In Toledo, Ohio, pavement milling and grinding are essential practices for maintaining the city's roadways, ensuring their longevity, safety, and efficiency within the transportation network. These processes involve precise removal of damaged asphalt or concrete layers from roads, airports, and other structures to facilitate repairs and resurfacing. Toledo employs advanced machinery and sustainable methods, recycling the milled materials into new pavements, thereby reducing environmental impact and conserving resources. The city's approach not only addresses immediate road conditions but also lays a foundation for long-term maintenance, minimizing future repair needs. The precision of the milling and grinding operations, guided by assessments based on traffic patterns and pavement conditions, ensures a smooth and durable surface for both drivers and pedestrians. Toledo's commitment to innovative infrastructure maintenance through pavement milling and grinding positions it as a leader in sustainable public works practices, reducing costs and improving road quality while upholding environmental stewardship. These initiatives demonstrate the city's dedication to integrating modern technology with sustainability, setting a benchmark for cities worldwide.

Pavement milling and grinding are critical processes in maintaining robust road networks. This article delves into their significance, particularly within Toledo, Ohio’s infrastructure maintenance strategies. We will explore the necessity of these operations, the equipment and techniques involved, and share insights from real-world applications in Toledo. By understanding the intricacies of pavement milling and grinding, communities can enhance safety, extend pavement lifespans, and improve overall travel experiences. Join us as we examine the transformative impact of these practices on Toledo’s roadways.

- Understanding Pavement Milling and Grinding: An Overview

- The Role of Pavement Milling and Grinding in Toledo, Ohio's Infrastructure Maintenance

- Assessing the Necessity for Pavement Milling and Grinding Operations

- The Process of Pavement Milling and Grinding: Equipment, Techniques, and Best Practices

- Case Study: Pavement Milling and Grinding Projects in Toledo, Ohio

Understanding Pavement Milling and Grinding: An Overview

Pavement milling and grinding are critical processes in the maintenance and rehabilitation of roadways, which are essential for safe and efficient transportation networks. These techniques involve the removal of the surface course or layers of a pavement structure to prepare it for repair or resurfacing. The equipment used for pavement milling typically consists of a milling machine that cuts into the pavement, removing specified depths with precision. This process is often the first step in a comprehensive pavement rehabilitation project and plays a significant role in ensuring the longevity and performance of the road. In Toledo, Ohio, for instance, these operations are executed by specialized crews who adhere to strict guidelines and utilize advanced machinery to perform milling and grinding tasks effectively. The process not only removes damaged or worn-out asphalt but also recycles the material, which can then be reused in new pavement construction, thereby supporting sustainable infrastructure practices. The precision of pavement milling and grinding ensures that the subsequent layers, once repaired or resurfaced, can bond effectively with the existing road structure, creating a smooth and durable road surface. This meticulous approach to pavement maintenance is vital for the upkeep of Toledo’s roadways and contributes to the overall safety and mobility of its residents and visitors.

The Role of Pavement Milling and Grinding in Toledo, Ohio's Infrastructure Maintenance

In Toledo, Ohio’s commitment to maintaining robust infrastructure, pavement milling and grinding play a pivotal role in the rehabilitation process. These techniques are integral to the city’s approach to infrastructure upkeep, as they facilitate the efficient removal of damaged or aged asphalt surfaces. Pavement milling and grinding in Toledo involves machinery that precisely cuts and grinds the existing pavement into uniform pieces, which are then removed for recycling. This process exposes the underlying layers, allowing city crews to assess their condition and make necessary repairs. The debris resulting from this operation is repurposed into new pavement materials, demonstrating Toledo’s dedication to sustainable practices within its public works initiatives. The recycle and reuse of these materials not only promotes environmental responsibility but also optimizes resource management, reducing the need for virgin materials and lowering associated costs.

The impact of this meticulous milling and grinding process extends beyond environmental considerations; it is instrumental in ensuring the longevity and safety of Toledo’s roadways. By removing surface irregularities and addressing sub-surface defects, the city’s roads become smoother and safer for drivers and pedestrians alike. This approach to pavement maintenance enhances the overall driving experience by minimizing tire and vehicle wear, which can translate into fuel savings and reduced environmental emissions. Furthermore, the consistent execution of these milling and grinding operations contributes to a predictable and maintainable infrastructure lifecycle for Toledo’s transportation network. As a result, the city’s roadways are not only rejuvenated but also prepared to withstand future wear and tear, ensuring that Toledo remains a leader in infrastructure maintenance through innovative pavement milling and grinding practices.

Assessing the Necessity for Pavement Milling and Grinding Operations

Pavement milling and grinding operations play a pivotal role in maintaining the integrity and safety of roadways. These processes involve the removal of the surface layer or specific sections of a paved area to repair or resurface roads, airports, and other infrastructure. In Toledo, Ohio, as in many cities, these operations are conducted to address issues such as pavement deterioration, surface irregularities, and to prepare for overlay applications. The necessity for milling and grinding is assessed through a comprehensive evaluation of the pavement condition. This includes analyzing traffic volumes, identifying areas with significant wear or damage, and evaluating the thickness and condition of the existing pavement layers. The data collected from these assessments helps determine the appropriate depth of milling required to achieve a safe and smooth driving surface. Advanced technologies like infrared scanning and 3D laser mapping are employed to pinpoint precise areas that need attention, ensuring efficient use of resources and minimizing disruptions to traffic flow. By utilizing pavement milling and grinding operations in Toledo, Ohio, city planners can effectively extend the lifespan of roadways, enhance safety, and maintain a high standard of infrastructure quality for residents and commuters alike. These operations are not only critical for immediate repairs but also serve as a foundation for long-term pavement management strategies, contributing to the overall sustainability and performance of the transportation network.

The Process of Pavement Milling and Grinding: Equipment, Techniques, and Best Practices

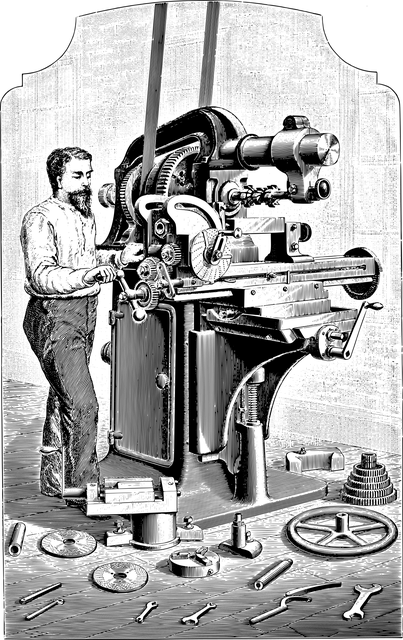

Pavement milling and grinding are critical processes in road maintenance and reconstruction, ensuring the longevity and safety of our transportation infrastructure. These operations involve removing the surface layer of asphalt or concrete pavement to repair or resurface roads. The process begins with the selection of appropriate equipment, which includes specialized milling machines and grinding equipment. These machines come in various sizes and capabilities, designed for different types of pavement structures and conditions. For instance, in Toledo, Ohio, where diverse climates and traffic volumes challenge roadways, operators use milling machines equipped with carbide-tipped teeth to precisely cut the pavement layer to a specified depth.

In Toledo, Ohio, as in many locations, the success of pavement milling and grinding operations hinges on the expertise of the operators and adherence to best practices. These include careful planning and precise execution to minimize disruptions to traffic flow and ensure the highest quality finish for the new surface. Techniques involve setting up the equipment with the correct blade configuration, adjusting the cutting depth according to project specifications, and maintaining optimal speeds to achieve a uniform removal of pavement material. Additionally, environmental considerations are paramount; best practices include managing dust suppression, recycling milled materials into new pavements, and employing noise mitigation measures during the process. This not only contributes to sustainability but also ensures that the community experiences minimal inconvenience during these necessary road improvement projects.

Case Study: Pavement Milling and Grinding Projects in Toledo, Ohio

In Toledo, Ohio, the city has undertaken a series of pavement milling and grinding projects that exemplify innovative infrastructure maintenance. These initiatives are not merely about repairing worn-out roads; they represent a strategic approach to maintaining the longevity and safety of the transportation network. Pavement milling and grinding involve the precise removal of asphalt layers from existing pavements, which is then repurposed or recycled. This process allows for the inspection and repair of sub-surface issues, ensuring that any structural deficiencies are addressed before fresh asphalt is laid down. The Toledo projects have utilized state-of-the-art milling machines that can control both depth and pattern, enabling them to remove only the necessary amount of material. This targeted approach minimizes waste and reduces the environmental impact associated with road maintenance. Furthermore, the ground-up material from the pavement is often reused in new construction, promoting sustainability within the city’s infrastructure projects. The end result is a smoother, more durable road surface that not only enhances driver safety but also contributes to extended pavement life and cost savings over time. These milling and grinding initiatives in Toledo serve as a model for other cities looking to implement efficient and eco-friendly pavement rehabilitation practices.