Insulated medical packaging is revolutionizing pharmaceutical logistics with advanced design, materials, and real-time monitoring for temperature-sensitive medications and vaccines. Sustainable medical packaging options minimize environmental impact while custom medical packaging caters to unique healthcare needs, enhancing patient safety and regulatory compliance. These innovations not only preserve product integrity but also support global sustainability goals by reducing waste and carbon emissions, aligning with the growing demand for eco-friendly solutions in healthcare practices.

Insulated medical packaging is transforming healthcare logistics, ensuring temperature-sensitive medications and treatments remain effective during transit. This comprehensive guide explores the multifaceted world of medical packaging solutions, highlighting the essential features and benefits that make it indispensable. We delve into the growing emphasis on sustainable medical packaging and how customization options cater to diverse needs. From innovative applications to emerging trends, discover how these advancements are shaping the future of healthcare delivery worldwide.

- Understanding Insulated Medical Packaging: Essential Features and Benefits

- The Role of Sustainable Practices in Modern Medical Packaging Solutions

- Customization Options: Creating Tailored Medical Packaging for Specific Needs

- Applications: Where Insulated Medical Packaging Makes a Difference

- Future Trends: Innovations Shaping the Landscape of Medical Packaging

Understanding Insulated Medical Packaging: Essential Features and Benefits

Insulated medical packaging plays a vital role in ensuring the safe and effective transport of pharmaceuticals, vaccines, and other temperature-sensitive medical goods. These innovative medical packaging solutions are designed to protect contents from environmental factors, particularly extreme temperatures. By maintaining consistent and controlled conditions, they safeguard the integrity and potency of medications and biologics during distribution.

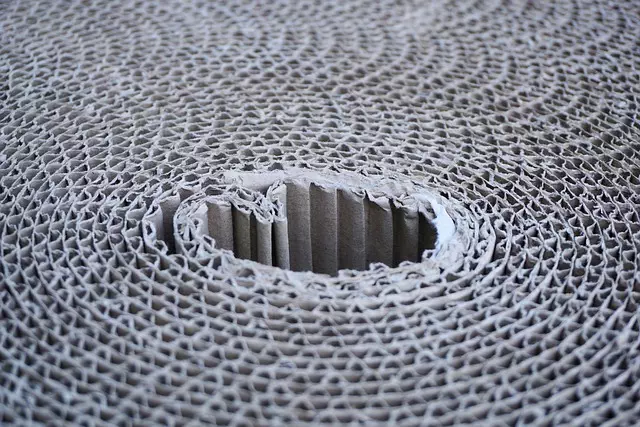

Key features include insulation materials that trap heat or cold, robust construction for durability and protection against damage, and integrated monitoring systems to track temperature fluctuations in real-time. The benefits extend beyond product preservation; sustainable medical packaging options minimize environmental impact while offering tailored solutions for specific medical products. Custom medical packaging allows healthcare providers and manufacturers to address unique requirements, enhancing patient safety and ensuring compliance with regulatory standards.

The Role of Sustainable Practices in Modern Medical Packaging Solutions

In today’s world, sustainable practices play a pivotal role in shaping the future of medical packaging solutions. The demand for eco-friendly and biodegradable materials has surged due to the growing awareness of environmental impact. Sustainable medical packaging is not just a trend but an essential shift towards reducing waste and carbon footprint. Manufacturers are now offering custom medical packaging options that prioritize using recycled, recyclable, or compostable materials, ensuring products remain safe while minimizing ecological damage.

This approach aligns with global sustainability goals, allowing healthcare providers to transport medications and medical devices responsibly. Customization enables precise design for specific products, balancing protection with environmental considerations. As a result, sustainable medical packaging not only supports healthcare’s mission to improve patient outcomes but also contributes to preserving the planet for future generations.

Customization Options: Creating Tailored Medical Packaging for Specific Needs

Insulated medical packaging offers a realm of customization options, allowing for tailored medical packaging solutions to meet specific needs. From specialized shapes and sizes to advanced insulation materials and temperature control systems, manufacturers can create sustainable medical packaging that ensures the safe transport of pharmaceuticals, vaccines, and other temperature-sensitive goods. Custom medical packaging goes beyond basic design, incorporating innovative features like GPS tracking, tamper-evident seals, and real-time monitoring capabilities to enhance safety and efficiency throughout the supply chain.

These customization possibilities are driven by evolving demands in healthcare logistics, where ensuring product integrity is paramount. By leveraging cutting-edge materials and technologies, custom medical packaging can address unique challenges related to moisture control, shock absorption, and barrier protection, all while maintaining compliance with stringent regulatory standards. This level of adaptability positions insulated medical packaging as a game-changer, revolutionizing how healthcare products are packaged, transported, and delivered worldwide.

Applications: Where Insulated Medical Packaging Makes a Difference

Insulated medical packaging plays a pivotal role in various sectors, offering specialized solutions to ensure the safe transportation of temperature-sensitive medical goods. From pharmaceuticals to diagnostics, these innovative packaging designs maintain critical storage conditions throughout the supply chain. For instance, they are invaluable for shipping vaccines, ensuring their potency and efficacy reach patients globally.

Sustainable medical packaging is another area where insulated options shine. Customized insulators made from eco-friendly materials reduce waste and environmental impact without compromising performance. This not only aligns with growing sustainability goals but also provides businesses with a competitive edge by appealing to environmentally conscious consumers and adhering to regulatory standards, thereby driving the demand for efficient and eco-friendly medical packaging solutions.

Future Trends: Innovations Shaping the Landscape of Medical Packaging

The future of medical packaging is poised for significant shifts, driven by advancements in technology and a growing emphasis on sustainability. Innovations such as smart packaging, which integrates sensors to monitor temperature and humidity, are set to revolutionize how medical goods are transported, ensuring their integrity and safety throughout the supply chain. These technologies not only enhance product quality but also offer real-time data for better inventory management.

Additionally, there’s a rising trend towards sustainable medical packaging solutions, with eco-friendly materials like biodegradable plastics and recycled content gaining traction. Custom medical packaging is another area of focus, allowing manufacturers to design specific solutions tailored to unique medical products. This approach not only improves product protection but also reduces waste by eliminating over-packaging, aligning with global efforts to create a more sustainable healthcare industry.