Steel packaging solutions are gaining popularity in heavy machinery industries for their exceptional strength and durability. Custom steel packaging, tailored to specific part dimensions and weights, offers superior protection during transportation and storage, ensuring safe delivery of mechanical components. This eco-friendly approach replaces traditional materials like plastic and wood with recyclable steel, reducing waste and carbon footprints while addressing environmental concerns. As a result, it becomes a strategic choice for manufacturers to maintain market competitiveness while adhering to sustainable practices.

In an era driven by robust industrial growth, the demand for reliable steel packaging solutions for heavy machinery is at an all-time high. This article delves into the multifaceted world of steel packaging, exploring its role in enhancing product durability and safety. We dissect the growing trend towards sustainable steel packaging, while also shedding light on how custom steel packaging designs cater to the unique protection needs of specialized machinery. Discover why these solutions are transforming industries worldwide.

- Steel Packaging Solutions for Heavy Machinery: Strength and Durability

- The Shift Towards Sustainable Steel Packaging in the Industry

- Custom Steel Packaging: Tailoring Protection for Unique Challenges

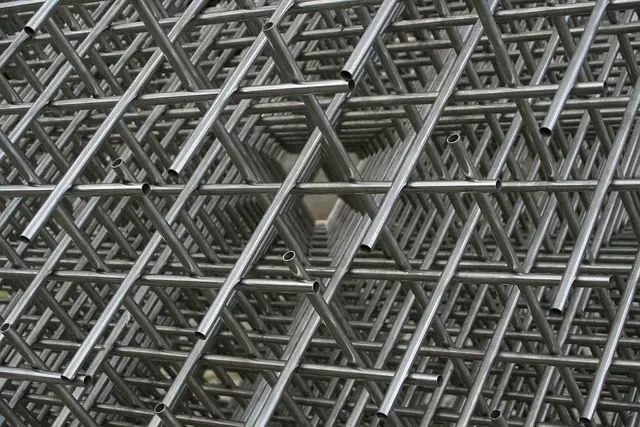

Steel Packaging Solutions for Heavy Machinery: Strength and Durability

Steel packaging solutions for heavy machinery are renowned for their unparalleled strength and durability. This robust material is specifically designed to withstand extreme conditions, making it ideal for protecting intricate mechanical parts during transportation and storage. Unlike alternative materials that may crack or deform under pressure, steel maintains its integrity, ensuring the safe delivery of critical components.

Moreover, the versatility of sustainable steel packaging offers a range of custom solutions tailored to specific machinery needs. From creating protective cases for oversized engines to designing robust crates for delicate sensors, steel’s malleability allows for intricate designs that perfectly cradle and secure various parts. This level of customization not only guarantees optimal protection but also enhances overall logistics efficiency through streamlined handling and reduced risk of damage during the supply chain.

The Shift Towards Sustainable Steel Packaging in the Industry

The manufacturing and construction industries, known for their reliance on robust materials, are increasingly embracing sustainable practices, and this shift is evident in their approach to packaging. Traditional plastic and wooden packaging solutions are being re-evaluated due to environmental concerns, leading to a growing adoption of steel packaging. This change is particularly notable among heavy machinery manufacturers who require durable and long-lasting packaging for their products.

Custom steel packaging offers an eco-friendly alternative that can be designed to meet specific product needs. With the ability to create robust, reusable containers, steel packaging solutions provide a viable route towards reducing waste and carbon footprints. As sustainability becomes a key focus for businesses worldwide, embracing sustainable steel packaging is not just an environmentally conscious decision but also a strategic move to stay competitive in an ever-evolving market.

Custom Steel Packaging: Tailoring Protection for Unique Challenges

In the realm of heavy machinery, where components are often large, intricate, and highly specialized, one-size-fits-all approaches to packaging simply won’t do. This is where custom steel packaging solutions step in as a game-changer. By working closely with manufacturers, steel packaging specialists can create tailored designs that not only accommodate the unique dimensions and weight of heavy machinery parts but also offer unparalleled protection during transit and storage.

Custom steel packaging goes beyond simple containment; it emphasizes sustainability by utilizing recycled materials and implementing eco-friendly production processes. These solutions are designed to withstand extreme conditions, including harsh weather, rough handling, and even potentially dangerous environments. The result? Machinery arrives at its destination in pristine condition, ensuring optimal performance and minimizing the risk of costly damage or downtime.