Toledo, Ohio is recognized for its cutting-edge advancements and innovation in automotive packaging design. Local manufacturers excel in creating robust solutions that protect vehicle components from environmental factors and transportation hazards, leveraging advanced materials and engineering expertise to ensure safety and support lean manufacturing processes. Toledo's packaging designs are not only durable and efficient but also focus on sustainability and adaptability for future industry shifts, such as the rise of electric vehicles and autonomous technologies. The city's dedication to research and development, along with predictive analytics and simulation for environmental testing, ensures that its automotive packaging design solutions remain at the forefront of quality, innovation, and efficiency, contributing to cost savings and a reduced carbon footprint in vehicle production. Toledo's standing as a leader in automotive packaging design is underscored by its commitment to meeting the stringent standards set by industry leaders and its ability to navigate the evolving automotive landscape with agility and foresight.

exploration of automotive packaging durability takes readers through the robust engineering and material science at the heart of Toledo, Ohio’s automotive packaging design prowess. This article delves into the innovative strategies and advanced materials that fortify vehicle components for transport. From the resilient designs born on the manufacturing floors of Toledo to the forward-thinking trends that are shaping the future of the industry, we uncover how these solutions not only protect parts during transit but also contribute to the overall efficiency and safety of the automotive supply chain. Join us as we navigate the intricacies of automotive packaging design, highlighting the exceptional work being done in this field.

- Navigating the Resilience of Automotive Packaging Design in Toledo, Ohio

- Material Mastery: The Role of Advanced Materials in Automotive Packaging Solutions

- Innovative Approaches to Enhancing Durability in Automotive Component Packaging

- Case Study: Success Stories in Automotive Packaging Design from Toledo's Industry Pioneers

- Future-Proofing Automotive Packaging: Predictions and Trends Shaping Tomorrow's Solutions in Toledo, Ohio

Navigating the Resilience of Automotive Packaging Design in Toledo, Ohio

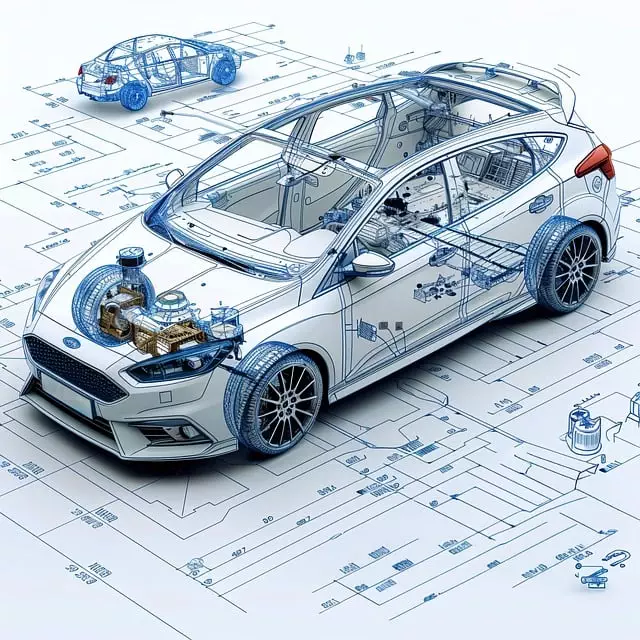

In Toledo, Ohio, the automotive packaging design industry is a testament to the region’s long-standing commitment to innovation and quality in the sector. Local manufacturers specializing in automotive packaging design are renowned for their resilient materials and robust construction methods, which are designed to withstand the rigors of transportation and storage. These packages protect critical components from environmental factors, impact, and other potential hazards during transit. The city’s proximity to major automotive producers has fostered a competitive environment where suppliers continuously improve their designs to meet the exacting standards required by these industry giants. Advanced technologies in materials science and engineering are employed here to ensure that each package not only safeguards its contents but also contributes to lean manufacturing practices, reducing waste and increasing efficiency.

The resilience of automotive packaging design in Toledo is not merely a response to the demands of the automotive industry but also a reflection of the region’s adaptive and forward-thinking approach. Suppliers in Toledo are at the forefront of developing packaging solutions that address new challenges, such as the integration of lightweight materials without compromising on protection. This commitment to both innovation and durability has solidified Toledo’s position as a hub for automotive packaging design excellence. The city’s dedication to maintaining high standards in this niche market ensures that vehicles across various segments receive the utmost care from production lines to dealerships, cementing Toledo’s reputation for quality and reliability in the automotive industry.

Material Mastery: The Role of Advanced Materials in Automotive Packaging Solutions

In the realm of automotive packaging design, Toledo Ohio stands out as a pivotal hub where material mastery plays a crucial role in advancing the field. The region’s long-standing legacy in the automotive industry has fostered a fertile ground for innovation, particularly in the development and application of advanced materials. These materials are not just any off-the-shelf options; they are meticulously selected and engineered to meet the stringent demands of the automotive sector. The focus is on enhancing durability, reliability, and safety while optimizing weight and reducing environmental impact. In Toledo, leading packaging design entities collaborate with material scientists to create solutions that protect sensitive components from the rigors of transportation and storage. This synergy ensures that each package is a testament to precision engineering, capable of safeguarding against shock, vibration, and other potential hazards during transit. The integration of high-performance materials, such as composites and plastics with enhanced properties, into the automotive packaging design process in Toledo underscores the importance of material selection and innovation. These advanced materials not only contribute to the longevity and integrity of the packaged goods but also reflect the industry’s commitment to sustainable practices, ensuring that the automotive supply chain remains robust and resilient.

Innovative Approaches to Enhancing Durability in Automotive Component Packaging

Innovations in automotive packaging design are pivotal for ensuring the durability and protection of components from Toledo, Ohio to global markets. In Toledo, a city historically associated with the automotive industry, advancements in packaging techniques are being pioneered to meet the stringent demands of vehicle part resilience. These developments focus on creating packaging solutions that can withstand the rigors of transportation, which includes protecting against shocks, vibrations, and environmental factors that could compromise component integrity during transit. By employing sophisticated materials and designs, these packages not only safeguard the components but also optimize space for increased efficiency in shipping and handling.

The evolution of automotive packaging design goes beyond mere containment; it encompasses a systematic approach to protect sensitive parts from potential damage. This involves rigorous testing protocols that simulate real-world conditions, ensuring that each package is tailored to the specific needs of its contents. Additionally, there is a growing emphasis on sustainable practices within the packaging design process, aiming to minimize environmental impact without compromising on durability and performance. This holistic approach not only enhances product protection but also positions companies at the forefront of innovation in automotive packaging solutions, setting new industry benchmarks for component longevity and safety.

Case Study: Success Stories in Automotive Packaging Design from Toledo's Industry Pioneers

Toledo, Ohio, has long been a hub for innovative automotive packaging design, with industry pioneers setting benchmarks in the field. One notable success story emerges from a local firm that specialized in designing packaging solutions for the automotive sector. Their approach to automotive packaging design in Toledo, Ohio, was both methodical and visionary, leveraging advanced materials and cutting-edge technology to create packages that not only protected the vehicle components but also reduced weight and improved overall efficiency in production lines. This company’s commitment to excellence led to a significant reduction in damages during transportation, which translated to substantial cost savings for their clients. Their design ingenuity was not limited to functionality; aesthetics played a crucial role as well, with packaging that effectively branded the products and provided an unboxing experience that resonated with end-users. This fusion of form and function in automotive packaging design has become a hallmark of Toledo’s industry leaders, who continue to push the boundaries of what is possible, ensuring their clients remain at the forefront of the automotive industry.

Future-Proofing Automotive Packaging: Predictions and Trends Shaping Tomorrow's Solutions in Toledo, Ohio

In Toledo, Ohio, the landscape of automotive packaging is undergoing a transformative shift with a focus on future-proofing designs. The city’s rich history in automotive manufacturing has laid a solid foundation for innovation within its automotive packaging design sector. As industry leaders and designers in Toledo look ahead, they are prioritizing sustainability and resilience in their packaging solutions to meet the evolving demands of the automotive sector. These forward-thinking designs are not only optimized for current vehicle models but are also adaptable to accommodate future advancements, such as electric vehicles and autonomous technologies. The integration of smart materials that can withstand environmental stressors and new regulatory compliance requirements is a key trend shaping tomorrow’s automotive packaging solutions in Toledo. By investing in research and development, local experts are ensuring that their designs will remain relevant and effective, even as the automotive industry continues its rapid evolution.

The predictive analytics and data-driven approach employed by Toledo’s automotive packaging design professionals are setting new benchmarks for durability and efficiency. These professionals are leveraging advanced software tools to simulate various environmental conditions, ensuring that each package is rigorously tested before reaching production. The collaboration between designers, engineers, and material scientists in Toledo is leading to breakthroughs in lightweighting and material optimization, which not only contribute to cost savings but also have a positive impact on the overall carbon footprint of vehicle production. As the automotive industry heads towards an electrified and increasingly autonomous future, Toledo’s commitment to pioneering automotive packaging design will ensure that its contributions remain at the forefront of innovation.