CNC machining, a precision manufacturing process using computer-controlled machines, is transforming the packaging sector in Holland, Ohio. This technology enables businesses to create custom, intricately designed packaging components with unparalleled accuracy and quality. By adopting CNC machining, local manufacturers streamline operations, rapidly prototype, and customize products to meet dynamic consumer demands. The versatility of CNC machining in handling various materials and its ability to accommodate intricate designs make it a valuable asset for diverse packaging applications, offering efficient, cost-effective solutions without sacrificing design complexity. This advanced technology has revolutionized the industry, providing Holland, Ohio manufacturers with significant advantages in productivity, product protection, presentation, material usage, and the ability to fulfill complex orders quickly and consistently.

“Discover how CNC machining for packaging industry Holland Ohio is transforming production with custom CNC-machined packaging components. This cutting-edge technology offers unprecedented efficiency and precision. In this comprehensive guide, we explore the benefits of CNC machining in packaging processes, highlighting its impact on modern facilities. From optimized space utilization to enhanced product quality, adjustable steel racks play a pivotal role. Dive into our article to uncover real-world case studies showcasing successful CNC machining implementations in packaging solutions.”

- Understanding CNC Machining for Packaging Industry Holland Ohio

- Custom CNC-Machined Packaging Components: Unlocking Efficiency

- Benefits of CNC Machining in Packaging Processes

- The Role of Adjustable Steel Racks in Modern Packaging Facilities

- Case Studies: Success Stories of CNC Machining in Packaging Solutions

Understanding CNC Machining for Packaging Industry Holland Ohio

In the world of modern packaging, efficiency and precision are paramount. This is where CNC (Computer Numerical Control) machining plays a pivotal role for industries like Holland, Ohio’s thriving packaging sector. CNC machining is a manufacturing process that utilizes computer-controlled machines to cut, shape, and form materials with incredible accuracy. For the packaging industry, this technology offers unparalleled benefits, enabling the production of custom CNC-machined packaging components. From creating intricate designs to ensuring consistent quality, CNC machining ensures every package is not only functional but also aesthetically pleasing.

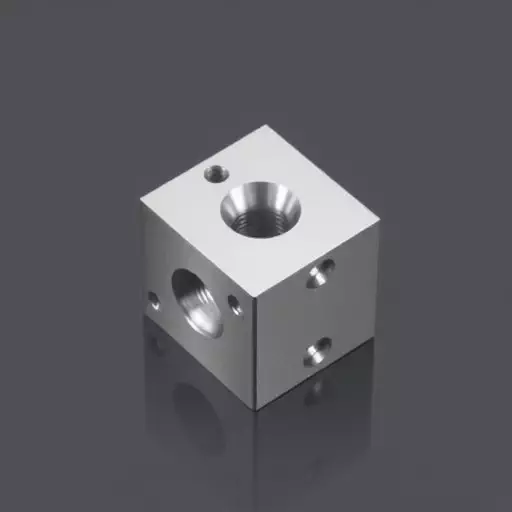

By implementing CNC machining for packaging in Holland, Ohio, local businesses can streamline their operations and stay competitive in the market. The process allows for rapid prototyping and customization, enabling companies to adapt quickly to ever-changing consumer demands. Moreover, CNC machinery’s ability to handle a wide range of materials, from plastics to metals, makes it versatile enough for diverse packaging applications. This technology is revolutionizing the industry by offering efficient, cost-effective solutions without compromising on quality or design complexity.

Custom CNC-Machined Packaging Components: Unlocking Efficiency

In today’s competitive market, efficiency is key for any business looking to stay ahead. Custom CNC-machined packaging components offer a game-changer solution for companies in the packaging industry. By utilizing advanced CNC machining techniques, manufacturers in Holland, Ohio, can create precise and tailored parts that streamline production processes. This technology allows for intricate designs and unique specifications, ensuring each component fits perfectly with adjustable steel racks or other packaging systems.

The benefits of CNC machining in packaging are numerous. It enhances productivity by reducing manual labor and minimizing errors, allowing businesses to meet tight deadlines. Custom components can also improve the overall quality of packaging, leading to better product protection and presentations. Furthermore, CNC machinery enables manufacturers to optimize material usage, resulting in cost savings and a smaller environmental footprint—a crucial aspect for eco-conscious companies.

Benefits of CNC Machining in Packaging Processes

In the realm of modern packaging, CNC (Computer Numerical Control) machining has emerged as a game-changer for manufacturers in Holland, Ohio, and beyond. This advanced manufacturing process offers a multitude of benefits specifically tailored to the packaging industry. By utilizing custom CNC-machined packaging components, businesses can achieve unparalleled precision and efficiency in their production lines. With CNC machining, creating intricate and complex shapes becomes straightforward, enabling the design of unique and specialized packages that enhance product presentation and protection.

Moreover, CNC machining for the packaging industry streamlines production, reduces waste, and minimizes errors. The automation and accuracy inherent in CNC machines ensure consistent quality across every component, resulting in faster assembly times and lower labor costs. This technology is particularly valuable for custom order fulfillment, where diverse and varied packaging demands can be efficiently met without compromising on quality or speed.

The Role of Adjustable Steel Racks in Modern Packaging Facilities

In modern packaging facilities, adjustable steel racks play a pivotal role in optimizing space and enhancing operational efficiency. These versatile storage solutions are designed to accommodate the dynamic nature of packaging operations, where product sizes, weights, and volumes can vary drastically. With CNC machining for packaging industry Holland Ohio leading the way, custom CNC-machined packaging components have become integral to creating these adjustable racks. This technology ensures precision engineering, allowing for precise adjustments to fit various product requirements, thereby maximizing shelf life and minimizing waste.

The benefits of CNC machining in packaging are manifold. It enables the production of complex rack designs that would be challenging or impossible with traditional manufacturing methods. Custom cnc-machined packaging components offer enhanced stability and durability, ensuring the safe storage and retrieval of goods. Moreover, these racks can be reconfigured quickly to adapt to changing market demands, new product lines, or facility layout adjustments, contributing to a more flexible and responsive packaging process.

Case Studies: Success Stories of CNC Machining in Packaging Solutions

The CNC machining for packaging industry Holland Ohio has seen remarkable success stories, revolutionizing traditional packaging solutions. Many businesses have embraced custom CNC-machined packaging components, reaping numerous benefits from this advanced manufacturing process. This technology enables precise and efficient creation of intricate packaging designs that were once deemed complex or unattainable.

By leveraging CNC machining in packaging, companies can achieve enhanced product protection, improved aesthetics, and reduced production times. Customized parts can be tailored to specific product dimensions and requirements, ensuring optimal fit and functionality. This level of precision is invaluable for industries demanding high-quality, reliable packaging solutions, solidifying the benefits of CNC machining in packaging across various sectors.