In recent years, a shift towards eco-friendly packaging has been led by the electronics industry in Holland, Ohio. Custom foam inserts, crafted with advanced CNC technology, offer precise protection for sensitive electronic components during transit. These inserts not only guard against physical damage but also mitigate electrostatic discharge (ESD) and static electricity, preventing data loss and equipment failure. ESD-safe foam is crucial for maintaining product integrity, while custom designs optimize packaging space and minimize waste. Holland, Ohio has emerged as a hub for such innovative, eco-conscious packaging solutions, with businesses leveraging CNC machining to create specialized foam products that adhere to strict environmental standards. This focus on sustainable packaging contributes to reduced product damage, return rates, and environmental impact, positioning Holland as a leader in the green packaging revolution.

In today’s eco-conscious landscape, the demand for sustainable packaging solutions is rising, particularly within the electronics industry. This shift has spurred innovation in advanced CNC technology, revolutionizing custom foam inserts for enhanced protection. Holland, Ohio, has emerged as a hub for these groundbreaking green packaging solutions. This article explores how specialized protective foam inserts, including ESD-safe and anti-static options, combine sustainability with superior static discharge protection, positioning them as an indispensable tool for electronics manufacturers.

- The Rise of Eco-Friendly Packaging in Electronics Protection

- Advanced CNC Technology: A Game Changer for Custom Foam Inserts

- Creating ESD-Safe Environments with Anti-Static Foam

- Holland, Ohio: A Hub for Innovative Green Packaging Solutions

- The Benefits of Protective Foam Inserts for Electronics

- Sustainability and Static Discharge Protection: A Winning Combination

The Rise of Eco-Friendly Packaging in Electronics Protection

In recent years, there’s been a significant shift towards eco-friendly packaging solutions across various industries. This trend is particularly noticeable in the electronics sector, where environmental considerations have led to innovative approaches for protecting sensitive components during transportation and storage. One such advancement is the increasing demand for protective foam inserts designed specifically for electronics, with locations like Holland, Ohio, leading the way in custom foam insert manufacturing.

These custom foam inserts not only offer superior protection against physical damage but also address critical issues like electrostatic discharge (ESD) and static electricity, which can be detrimental to electronic devices. ESD-safe foam inserts are particularly crucial for preventing data loss and equipment failure during the packaging and shipping process. By utilizing anti-static foam for electronics, manufacturers ensure that their products arrive at their destinations in optimal condition, contributing to both customer satisfaction and environmental sustainability.

Advanced CNC Technology: A Game Changer for Custom Foam Inserts

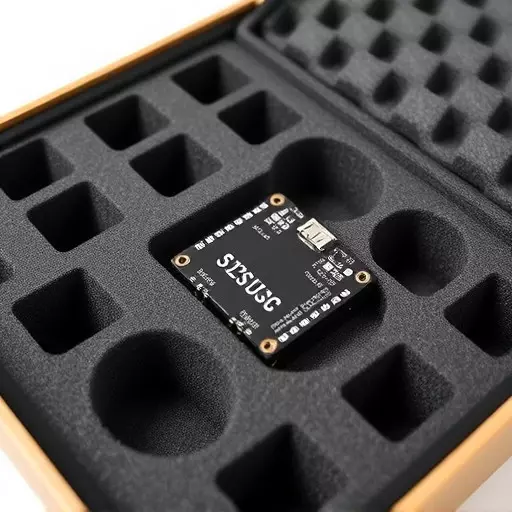

Advanced CNC technology has revolutionized the manufacturing process, particularly in the realm of custom foam inserts. This innovative approach allows for precise and intricate designs tailored to specific product requirements, making it an indispensable tool for industries seeking eco-friendly packaging solutions. When it comes to protective foam inserts for electronics in Holland, Ohio, or beyond, custom foam inserts offer unparalleled protection against damage during transit.

ESD-safe foam inserts, for instance, are crucial for safeguarding sensitive electronic components from electrostatic discharge (ESD). These anti-static foams play a vital role in maintaining the integrity of delicate gadgets by minimizing the risk of static electricity buildup, ensuring they arrive at their destination in optimal condition. With advanced CNC machining, manufacturers can create these specialized inserts with exacting specifications, catering to diverse product needs and contributing to sustainable packaging practices.

Creating ESD-Safe Environments with Anti-Static Foam

Creating ESD-Safe Environments with Anti-Static Foam

In the realm of eco-friendly packaging solutions, ensuring the safety and integrity of electronic components is paramount. One effective method to achieve this is by utilizing custom foam inserts that offer superior protection against electrostatic discharge (ESD). These protective foam inserts for electronics in Holland, Ohio, are designed to create ESD-safe environments, especially crucial for delicate components that can be damaged by even minor static charges. Anti-static foam for electronics plays a vital role in the packaging process, acting as a barrier against unwanted electrostatic buildup.

Custom foam inserts provide a tailored solution, allowing manufacturers to accommodate various component sizes and shapes while maintaining ESD safety. By incorporating these specialized inserts into packaging materials, companies can prevent costly damage during shipping and storage, ensuring that electronic devices arrive at their destination in optimal condition. This approach not only enhances product reliability but also underscores the commitment to eco-friendly practices by minimizing waste and maximizing resource efficiency.

Holland, Ohio: A Hub for Innovative Green Packaging Solutions

Holland, Ohio has emerged as a prominent center for cutting-edge, eco-friendly packaging solutions, driven by advancements in Computer Numerical Control (CNC) technology. The region is home to numerous innovative companies specializing in protective foam inserts for electronics, custom foam designs, ESD-safe foam inserts, and anti-static foams tailored for sensitive electronic components. This concentration of expertise has been catalyzed by the area’s thriving manufacturing base and its commitment to sustainability.

Local businesses leverage advanced CNC machining to create intricate, precise foam structures that safeguard products during transportation, ensuring they arrive in perfect condition. This precision craftsmanship, combined with a focus on sustainable materials, positions Holland as a leader in the green packaging revolution. The region’s companies are not just meeting but exceeding industry standards for environmental responsibility while delivering high-quality, specialized packaging solutions.

The Benefits of Protective Foam Inserts for Electronics

Protective foam inserts for electronics in Holland, Ohio, offer numerous benefits for packaging sensitive items like electronic devices. These custom foam inserts are designed to securely hold products in place while providing excellent shock absorption and impact protection during transportation. One of their key advantages is their ability to prevent damage caused by static electricity buildup—a significant concern in the electronics industry. ESD-safe (Electrostatic Discharge) foam inserts ensure that delicate components remain untouched, minimizing the risk of electrical failure or malfunction.

By incorporating anti-static foam for electronics into packaging designs, manufacturers can significantly reduce product damage and return rates. These foam inserts are not only cost-effective but also environmentally friendly when sourced responsibly, contributing to overall sustainability goals. Customizable shapes and sizes ensure perfect fitting, maximizing the interior space of packages while minimizing waste—a strategic move towards eco-friendly packaging solutions.

Sustainability and Static Discharge Protection: A Winning Combination

In today’s eco-conscious market, packaging plays a vital role in fostering sustainability. Advanced CNC (Computer Numerical Control) machining is revolutionizing the way we create protective packaging, especially for sensitive electronic components. One innovative solution gaining traction is the use of custom foam inserts designed to be both environmentally friendly and ESD (Electrostatic Discharge)-safe. These ESD-safe foam inserts, available in Holland, Ohio, are not just a trend but a necessity for industries looking to protect their products while minimizing environmental impact.

By employing CNC machining, manufacturers can produce precise, tailored foam inserts that perfectly accommodate electronic devices. This ensures secure packaging that protects against physical damage and, more importantly, static discharge. Anti-static foam for electronics is a game-changer, as it prevents harmful ESD events that could render delicate components useless. This combination of sustainability and static discharge protection offers businesses a competitive edge while promoting responsible waste management and the use of eco-friendly materials like protective foam inserts for electronics in Holland, Ohio.