Backflow preventers are essential for protecting water quality and public health in Fayetteville, especially in certified commercial settings and farms. A RPZ (Reduced Pressure Zone) backflow preventer is a robust solution for industrial sites, stopping contaminated water from flowing into potable sources. Proper installation by licensed professionals is crucial, following local regulations, to ensure ongoing effectiveness and safety. This safeguards both farmers and communities while adhering to strict environmental standards.

- Understanding Backflow Preventers: Their Role in Farm Safety

- Why Agricultural-Grade Backflow Preventers are Essential for Farms

- Certified Commercial Backflow Preventer Installation: A Step-by-Step Guide

- RPZ Backflow Preventer Setup: Optimizing Protection for Industrial Sites

- Best Practices for Maintaining and Testing Backflow Preventer Systems on Farms

Understanding Backflow Preventers: Their Role in Farm Safety

Backflow preventers play a crucial role in maintaining farm safety and water quality. These devices are designed to stop contaminated water from flowing back into potable water sources, protecting both farmers and their communities. In the event of a pressure surge or backup, backflow preventers create a physical barrier, ensuring that any harmful substances remain contained within the agricultural system. This is particularly important in Fayetteville and surrounding areas where certified commercial backflow preventer installation services are readily available to meet the unique needs of industrial sites and farms.

For agricultural operations, selecting the right backflow preventer setup, such as an RPZ (Reduced Pressure Zone) backflow preventer, is essential. This specialized equipment is tailored for industrial sites, offering advanced protection against a wide range of contaminants. By ensuring proper backflow preventer installation Fayetteville farms can safeguard their water supplies and comply with local regulations, fostering a safer and more sustainable agricultural environment.

Why Agricultural-Grade Backflow Preventers are Essential for Farms

Certified Commercial Backflow Preventer Installation: A Step-by-Step Guide

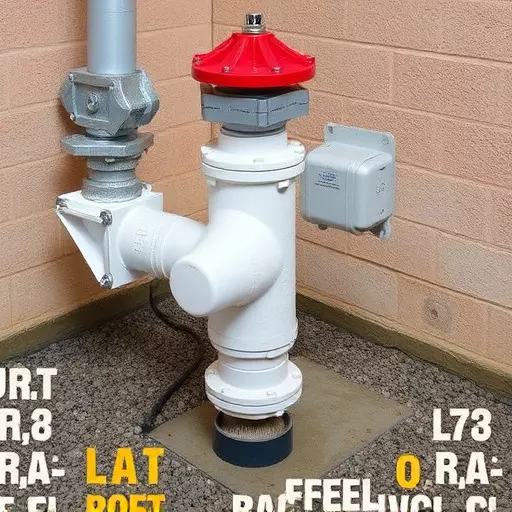

In the context of agricultural operations and farms, a certified commercial backflow preventer installation is a critical step in ensuring water safety and quality. The process involves a meticulous setup to safeguard potable water sources from potential contamination by chemicals or other pollutants. The RPZ (Reduced Pressure Zone) backflow preventer is particularly suited for industrial sites and agricultural settings due to its robust design, capable of withstanding demanding conditions.

A step-by-step guide for installing a certified commercial backflow preventer in Fayetteville or any agricultural setting begins by identifying the water supply and potential hazards. Next, select an appropriate RPZ device based on flow rates and chemical compatibility. Installation should be carried out by licensed professionals following local regulations. This involves connecting the backflow preventer to the main water line, ensuring proper pressure regulation, and installing check valves for added protection. Regular testing and maintenance are crucial to guarantee continuous effectiveness, thereby preserving the integrity of farm operations and the surrounding environment.

RPZ Backflow Preventer Setup: Optimizing Protection for Industrial Sites

In industrial sites and large farms, ensuring the safety of water supply lines is paramount. One effective solution is implementing a RPZ (Reduced Pressure Zone) backflow preventer setup. This device acts as a crucial barrier, guarding against hazardous backflow events that could contaminate potable water sources. A certified commercial backflow preventer installation in Fayetteville or any industrial area is essential to meet safety regulations and protect the community’s water supply.

The RPZ backflow preventer setup offers optimized protection by maintaining a constant pressure difference between the main supply and the farm’s internal plumbing. This ensures that even in the event of a breakdown or disruption upstream, the reverse flow of potentially contaminated water is prevented. By investing in this robust system, farms can safeguard their operations while adhering to strict environmental and health standards, making it a top choice for agricultural-grade backflow preventer setups.

Best Practices for Maintaining and Testing Backflow Preventer Systems on Farms