In Lake Orion, Michigan, advanced anti-corrosion glass treatments involve meticulous cleaning and application of specialized coatings like ceramic, silicone, or polymeric compounds using spraying, dipping, or brushing techniques. The glass then cures under heat or UV light to create a durable barrier against environmental corrosion, offering long-lasting protection for windows and other glass surfaces. Key services include corrosion-resistant glass coatings and glass anti-corrosion protection.

- Understanding Chemical-Resistant Glass Coatings: Their Role and Benefits

- The Process of Applying Anti-Corrosion Glass Treatments in Lake Orion, Michigan

- Choosing the Right Coating: Factors to Consider for Optimal Glass Protection

Understanding Chemical-Resistant Glass Coatings: Their Role and Benefits

Chemical-resistant glass coatings are specialized treatments designed to protect glass surfaces from corrosive substances, offering an effective solution for various industrial and commercial applications. These advanced coatings form a protective barrier on glass, preventing chemical penetration and potential damage. By applying anti-corrosion glass treatments, like those available in Lake Orion, Michigan, businesses can extend the lifespan of their glass infrastructure.

The role of corrosion-resistant glass coatings goes beyond mere protection; they enhance the durability and aesthetic appeal of glass. These coatings are particularly beneficial for environments with high chemical exposure, such as laboratories, food processing facilities, and industrial plants. By choosing glass anti-corrosion protection, facilities can ensure their equipment remains functional, safe, and visually appealing, contributing to a more efficient and productive workspace.

The Process of Applying Anti-Corrosion Glass Treatments in Lake Orion, Michigan

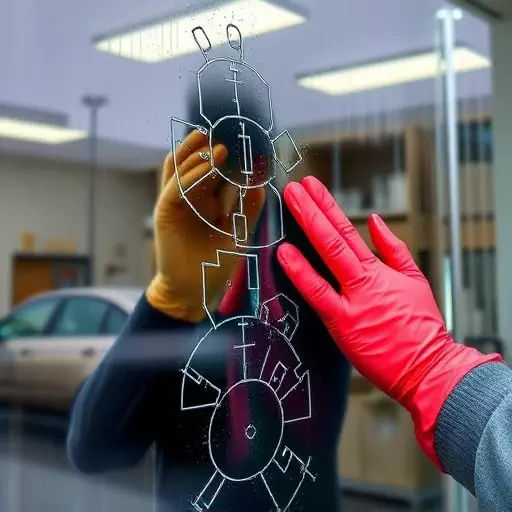

In Lake Orion, Michigan, the process of applying anti-corrosion glass treatments is a meticulous art that combines cutting-edge technology and specialized techniques to ensure superior protection for windows and other glass surfaces. The first step involves thorough cleaning and preparation of the glass to remove any contaminants or residue that could hinder the coating’s adhesion. This includes using specialized cleaning solutions and mechanical abrasives to create a smooth, clean surface.

Once the glass is ready, a range of advanced corrosion-resistant coatings are applied, tailored to meet specific needs. These coatings often include ceramic, silicone, or polymeric compounds known for their exceptional durability and resistance to chemical degradation. The application process typically involves spraying, dipping, or brushing, depending on the coating type and desired coverage. After application, the coated glass undergoes a curing process, where heat or UV light is used to harden the coating, making it an effective barrier against environmental elements and corrosion.

Choosing the Right Coating: Factors to Consider for Optimal Glass Protection

When selecting a chemical-resistant glass coating, several factors come into play to ensure optimal protection for your glass surfaces. One of the primary considerations is identifying the specific chemicals or substances that the glass will be exposed to. Different coatings offer varying levels of resistance against various chemicals, so understanding the environmental conditions is crucial. For instance, if the glass is in a laboratory setting, it might require a coating that can withstand frequent exposure to solvents or acids.

Additionally, the choice of coating should consider factors like temperature and humidity, as these elements can influence the durability and effectiveness of the protection. Some coatings are designed for harsh industrial environments with high temperatures and constant moisture, while others are suitable for more controlled settings. The surface preparation is another key aspect; proper cleaning, conditioning, and roughening of the glass can enhance the bonding of the coating, ensuring a longer-lasting anti-corrosion barrier.