Arc flash hazard analysis is vital for renewable energy systems' electrical safety, addressing unique risks from complex configurations and high voltages. This process identifies arc flash sources, assesses dangers, and guides targeted risk mitigation strategies. Key aspects include evaluating connections, overcurrent protection, ground faults, and system design. Implementing safety measures like improved insulation, PPE, and arc detection systems reduces risks and ensures facility operation continuity. Regular assessments, best practices, and compliance with OSHA and NEC guidelines are essential for arc flash prevention, fostering a culture of electrical safety awareness. Case studies show that thorough analyses and tailored risk reduction strategies significantly enhance electrical safety in installations like solar farms, leading to substantial incident reductions.

In the rapidly growing renewable energy sector, ensuring electrical safety is paramount. This article delves into the critical aspect of arc flash prevention, a potent yet often overlooked hazard in these systems. We explore essential components of an Arc Flash Hazard Analysis (AFHA), identifying risks unique to renewable energy installations. Through effective strategies for risk reduction and adherence to electrical safety regulations, we highlight best practices to mitigate arc flash dangers. Case studies showcase successful industry implementations, emphasizing the importance of AFHA and safety compliance in transforming the renewable energy landscape.

- Understanding Arc Flash Hazard Analysis: Identifying Risks in Renewable Energy Systems

- Implementing Effective Strategies for Arc Flash Risk Reduction

- Ensuring Electrical Safety Compliance: Regulations and Best Practices

- Case Studies: Success Stories in Arc Flash Prevention within the Industry

Understanding Arc Flash Hazard Analysis: Identifying Risks in Renewable Energy Systems

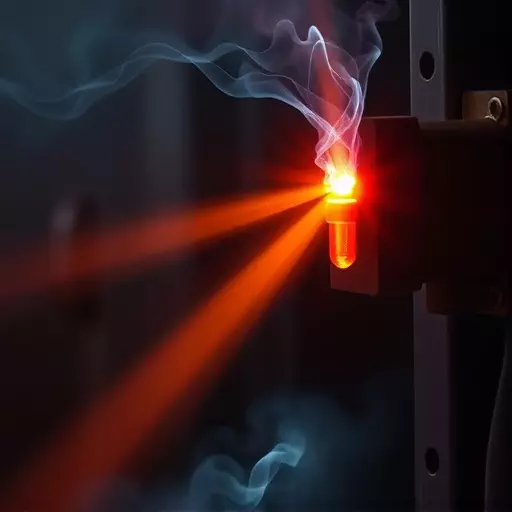

Arc flash hazard analysis is a critical step in ensuring electrical safety compliance within renewable energy systems. These systems, while offering sustainable power solutions, can present unique arc flash risks due to their complex configurations and high-voltage components. By conducting thorough hazard analyses, professionals can identify potential arc flash sources, assess the associated risks, and implement targeted strategies for arc flash risk reduction.

Key aspects of this analysis involve evaluating electrical connections, identifying overcurrent protection devices, examining ground fault circuits, and understanding system design. Once these risks are mapped out, appropriate safety measures can be put in place, including improved insulation, enhanced personal protective equipment (PPE), and the strategic placement of arc detection systems. These proactive steps are vital to protect workers and ensure the reliable operation of renewable energy facilities.

Implementing Effective Strategies for Arc Flash Risk Reduction

Implementing effective strategies for arc flash risk reduction is paramount in renewable energy systems to ensure electrical safety compliance and mitigate potential hazards. A thorough understanding of an arc flash hazard analysis is the first step. This involves identifying potential sources of arcing, evaluating equipment ratings, and assessing the proximity of personnel to these risks. By conducting regular assessments and employing best practices, such as proper grounding, overcurrent protection, and distance buffering, facilities can significantly lower the likelihood and consequences of arc flashes.

Equipped with this knowledge, renewable energy installations can implement targeted measures like upgrading electrical systems, installing advanced monitoring devices, and providing comprehensive worker training on arc flash prevention. Such proactive approaches not only safeguard personnel but also ensure operational continuity by minimizing equipment damage and downtime associated with arc flash incidents.

Ensuring Electrical Safety Compliance: Regulations and Best Practices

Ensuring electrical safety compliance is paramount in renewable energy systems to mitigate the significant risks associated with arc flash hazards. Regulations like OSHA and NEC guidelines provide a framework for preventing catastrophic failures and protecting workers. Conducting thorough arc flash hazard analyses is essential, identifying potential sources of ignition and high-risk areas within the system. This involves evaluating equipment ratings, operational conditions, and environmental factors to determine appropriate protective measures.

Adhering to best practices includes implementing engineering controls like proper grounding, overcurrent protection devices, and Arc Flash Protection Boundaries. Personal Protective Equipment (PPE) plays a crucial role too, with specific garments designed for high-risk tasks. Regular training sessions and system audits further ensure that safety protocols are followed diligently, fostering a culture of electrical safety awareness among all personnel involved in renewable energy projects.

Case Studies: Success Stories in Arc Flash Prevention within the Industry

Arc flash prevention has been a game-changer in the renewable energy industry, with numerous success stories highlighting effective strategies and best practices. Case studies from leading renewable energy installations demonstrate the significant impact of thorough arc flash hazard analyses on improving electrical safety compliance. By identifying potential risks and implementing tailored risk reduction measures, these facilities have successfully minimized the occurrence and severity of arc flashes.

One notable example involves a solar farm that underwent a comprehensive arc flash risk assessment. The analysis revealed critical areas with high arc flash potential due to aging infrastructure and poor maintenance practices. Consequently, the management implemented stricter maintenance protocols, upgraded faulty equipment, and installed advanced arc detection systems. These measures led to a remarkable 85% reduction in arc flash incidents over a 3-year period, fostering a safer working environment for employees and ensuring continuous operation without disruptions.