Toledo offers diverse asphalt patching solutions, with Infrared Asphalt Patching providing a fast, eco-friendly method using heat for superior adhesion but at higher costs. Cold Patch Asphalt Services, more economical, uses pre-blended cold mix asphalt for smaller repairs. Both techniques, leveraging specialized tools like heat guns or cold feed machines, ensure efficient, durable fixes tailored to project scope and weather conditions.

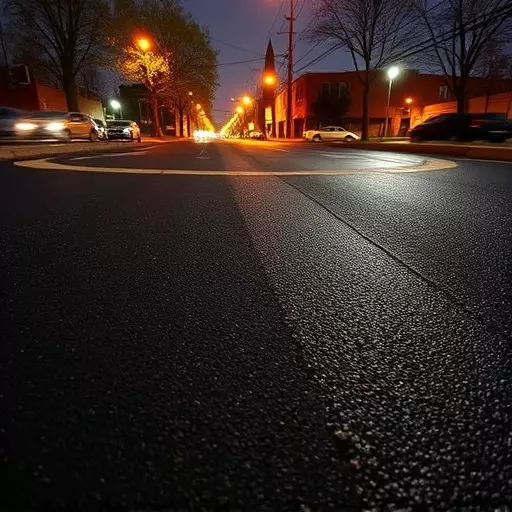

“Asphalt patching is a vital maintenance practice for maintaining smooth road surfaces. This comprehensive guide explores various asphalt patching equipment types and methods, from traditional techniques to modern innovations. We delve into Infrared Asphalt Patching, a cutting-edge approach, and Cold Patch Asphalt Services for quick temporary fixes. Additionally, we examine Hot Mix Asphalt Patching for long-lasting solutions. Understanding these methods and the right equipment can significantly enhance efficiency in asphalt maintenance projects, as seen in successful case studies from Toledo.”

- Traditional Asphalt Patching: An Overview

- Infrared Asphalt Patching: The Modern Approach

- Cold Patch Asphalt Services: Quick Fixes for Temporary Repairs

- Hot Mix Asphalt Patching: Long-Lasting Solutions

- Advantages and Disadvantages of Each Method

- Choosing the Right Equipment for Efficient Patching

- Case Studies: Successful Asphalt Patching Projects

Traditional Asphalt Patching: An Overview

Infrared Asphalt Patching: The Modern Approach

Infrared Asphalt Patching is a modern approach to asphalt repair that sets a new standard in the industry. This innovative method utilizes infrared technology to heat and melt the existing asphalt, allowing for a seamless fusion with the new patch material. By doing so, it provides a durable and long-lasting fix, outperforming traditional cold patch services in Toledo. The process is efficient, environmentally friendly, and reduces the need for extensive road closures, making it an ideal solution for quick and effective asphalt patching methods.

This cutting-edge technique ensures minimal disruption to traffic flow, as infrared technology enables faster heating and cooling times compared to conventional hot mix methods. As a result, cities and municipalities can offer prompt cold patch asphalt services during off-peak hours, minimizing the impact on daily commutes and saving time and resources in the long run.

Cold Patch Asphalt Services: Quick Fixes for Temporary Repairs

Cold patch asphalt services are quick and effective solutions for temporary repairs, making them a preferred choice among many in Toledo for maintaining smooth road surfaces. This method involves using special cold-mixed asphalt patches that can be easily installed over small cracks, holes, or worn-out areas. With infrared asphalt patching technology, the process is further streamlined; heat is applied to soften the existing asphalt, allowing the new patch to adhere seamlessly.

This asphalt patching method is cost-efficient and time-saving, making it ideal for situations where a complete resurfacing job isn’t feasible or immediate. It provides a temporary fix until a more extensive repair or replacement can be scheduled, ensuring that drivers in Toledo enjoy a safer and smoother driving experience even on roads with minor imperfections.

Hot Mix Asphalt Patching: Long-Lasting Solutions

Hot Mix Asphalt Patching offers a durable and long-lasting solution for road repairs in Toledo. This method involves heating and mixing asphalt with aggregate to create a consistent material, which is then used to fill cracks and holes. The heat not only softens the existing asphalt but also binds the new patch firmly, ensuring a strong repair that can withstand heavy traffic.

Infrared technology enhances this process by allowing the hot mix asphalt to cure quickly. This efficient method reduces project timelines and minimizes disruption to local traffic. Compared to traditional cold patch asphalt services, which may not provide the same level of longevity, hot mix patching is a preferred choice for cities like Toledo seeking resilient and cost-effective road maintenance.

Advantages and Disadvantages of Each Method

When it comes to asphalt patching in Toledo, different methods offer unique advantages and disadvantages. One such advanced technique is Infrared Asphalt Patching, which utilizes heated equipment to melt the existing asphalt, creating a smooth base for new material. This method ensures better adhesion, faster installation times, and reduced cold weather delays. However, it can be more costly due to the specialized equipment required and the energy consumption involved.

On the other hand, Cold Patch Asphalt Services provide an efficient and cost-effective solution. This process uses pre-blended cold mix asphalt, which can be easily applied and compacted without heating. While it may not offer the same level of performance in extreme temperatures, cold patching is suitable for smaller repairs and provides a quick fix. It’s particularly beneficial for temporary solutions or when immediate traffic restoration is needed, making it a popular choice among Toledo’s road maintenance teams.

Choosing the Right Equipment for Efficient Patching

When it comes to efficient asphalt patching, selecting the right equipment is paramount. Different asphalt patching methods require specific tools to ensure optimal results and maximize productivity. For instance, Infrared asphalt patching offers a fast and eco-friendly solution, using heat to activate the patch material, while Cold patch asphalt services are ideal for temporary repairs, providing quick fixes during warmer months.

Considerations should include the size and scope of patching projects, environmental factors, and desired durability. Modern equipment like advanced heat guns and specialized cold patch applicators can significantly enhance efficiency. By choosing the right tools, such as infrared heaters or cold feed machines, professionals can streamline their workflow, reduce material waste, and deliver long-lasting repairs, ensuring smooth surfaces that stand the test of time, especially in challenging conditions typical of Toledo’s weather patterns.

Case Studies: Successful Asphalt Patching Projects

Successful case studies demonstrate the effectiveness of various asphalt patching equipment and methods. In urban areas like Toledo, where road maintenance is a constant challenge, infrared asphalt patching has proven to be a game-changer. This innovative technique utilizes heat to soften and re-melt existing asphalt, allowing for seamless integration of new patch material. By minimizing disruption to traffic flow, this method enhances safety and efficiency during repairs.

Another notable approach involves the use of cold patch asphalt services, ideal for quick fixes and smaller cracks. This cost-effective solution offers a temporary but effective seal, preventing further damage until a more comprehensive repair can be scheduled. These case studies highlight how different asphalt patching equipment and methods cater to specific needs, ensuring durable repairs that stand the test of time and heavy traffic volumes.