Water-resistant custom automotive foam inserts are essential for protecting delicate parts during transit in Holland, Ohio. These specialized cushions prevent damage from moisture intrusion, warping, and corrosion, especially over long distances and through varying climates. For local manufacturers and distributors shipping fragile items, investing in these tailored solutions enhances product integrity, customer satisfaction, and market competitiveness.

Water-resistant foam inserts are revolutionizing the way we protect delicate automotive components during transit. This comprehensive guide delves into the world of these innovative solutions, exploring their crucial role in ensuring safe transportation. From understanding the technology to examining real-world applications in Holland, Ohio, we uncover how custom automotive foam inserts safeguard fragile parts. Discover why these inserts are essential for various industries and learn about their versatility in catering to unique automotive needs.

- Understanding Water-Resistant Foam Inserts: A Comprehensive Guide

- Automotive Foam Inserts for Shipping: Protecting Delicate Parts in Holland, Ohio

- Customization is Key: Creating Foam Inserts for Unique Automotive Needs

- The Role of Foam Inserts in Ensuring Safe Automotive Transportation

Understanding Water-Resistant Foam Inserts: A Comprehensive Guide

Water-resistant foam inserts are an essential component in protecting valuable and delicate automotive parts during shipping and handling, especially when transported over long distances or through varying weather conditions. These specialized inserts are designed to offer a secure fit within packaging, ensuring that fragile items like glass, mirrors, or custom-made automotive components remain intact and undisturbed. By utilizing water-resistant foam, shippers in Holland, Ohio, and beyond can mitigate the risks associated with moisture intrusion, which often leads to damage during transit.

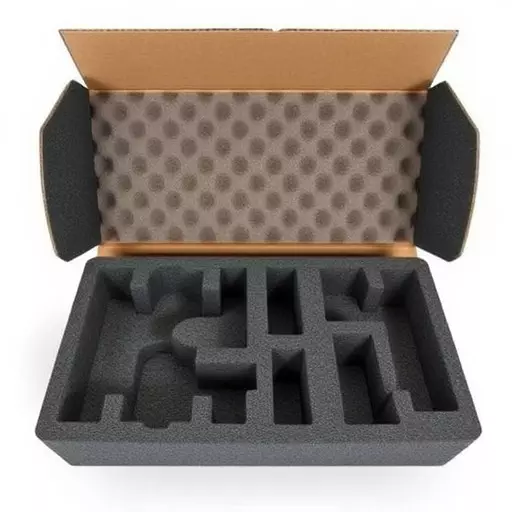

Custom automotive foam inserts are a key aspect of this protection strategy. These inserts are meticulously crafted to fit specific part dimensions, ensuring optimal coverage without causing any harm to the item’s surface. The water-resistant nature of these foams provides an extra layer of defense against humidity and rain, which can cause warping or corrosion in certain environments. This comprehensive guide aims to educate readers on the significance of such foam inserts, highlighting their role in preserving the integrity of automotive parts during the shipping process, particularly for businesses specializing in the transport of fragile items across diverse climates and landscapes.

Automotive Foam Inserts for Shipping: Protecting Delicate Parts in Holland, Ohio

In the bustling automotive industry of Holland, Ohio, the protection of delicate components during shipping is paramount to maintaining quality and ensuring timely deliveries. This is where custom automotive foam inserts play a pivotal role, offering a robust solution for safeguarding sensitive parts. These specialized foam materials are meticulously designed to fit various vehicle components, providing an ideal cushion that prevents damage during transit. By employing these innovative foam inserts, automotive manufacturers and distributors in Holland can confidently protect their fragile items, ensuring they reach customers without any adverse effects.

Custom automotive foam inserts offer a tailored approach to shipping vulnerabilities, addressing the unique dimensions and characteristics of each automotive part. This personalized touch ensures an effective barrier against shocks, vibrations, and impacts that could otherwise cause significant damage. With precision-cut foam designs, these inserts create a secure environment within packaging, minimizing movement and potential harm. As a result, businesses in Holland, Ohio, can rely on efficient shipping processes while maintaining the integrity of their automotive components, fostering customer satisfaction and building a reputation for excellence in the industry.

Customization is Key: Creating Foam Inserts for Unique Automotive Needs

In the world of automotive shipping and protection, customization is key when it comes to foam inserts. Each vehicle has unique dimensions and requirements for its interior components, especially when dealing with fragile or delicate parts. That’s where custom automotive foam inserts come into play. These specialized products are designed to perfectly fit specific car models, ensuring that every nook and cranny is accounted for. This level of customization is crucial for safeguarding valuable items during shipping, whether across Ohio or beyond.

For instance, when it comes to shipping sensitive automotive parts from Holland, Ohio, custom foam inserts offer a tailored solution. They can accommodate the precise shape and size of rare or specialized components, providing a snug fit that prevents shifting and potential damage during transit. This attention to detail ensures that fragile items arrive at their destination in the same condition they left, enhancing peace of mind for automotive professionals and enthusiasts alike.

The Role of Foam Inserts in Ensuring Safe Automotive Transportation

Automotive transportation is a complex process that demands meticulous attention to detail, especially when dealing with fragile and valuable components. This is where foam inserts play a pivotal role in ensuring safety during shipping and handling. Custom automotive foam inserts are designed specifically to cater to the unique needs of various vehicle parts, offering a protective cushion against impacts and shocks. These innovative solutions are particularly essential for high-value items, such as antique vehicles or specialized automotive machinery, requiring meticulous care throughout their journey from manufacturers in Holland, Ohio, to dealers or customers across the country.

By utilizing custom foam inserts, shipping companies can safeguard fragile automotive parts, reducing the risk of damage and ensuring that these valuable assets arrive at their destination in pristine condition. The carefully crafted design of these inserts provides a secure fit around the parts, minimizing movement during transit, and absorbing any potential energy from impacts, thus preventing dents, cracks, or more severe damage. This level of protection is invaluable for maintaining the integrity of automotive components, ensuring customer satisfaction, and upholding the reputation of both manufacturers and shipping services in the competitive market for automotive transportation solutions.