Backflow preventers are vital safety devices in Spring Lake, protecting potable water supplies from contamination. They come in various types, with reduced pressure backflow preventers (RPBP) for homes and more complex models for commercial use. Installation requires skilled technicians who assess needs, install devices, and ensure regulatory compliance, leading to secure plumbing systems. Regular maintenance and testing are crucial to keep these preventers effective, safeguarding water supplies from bacteria, chemicals, and sewer content. Property owners should understand these processes for both residential and commercial backflow preventer installations in Spring Lake.

“In Spring Lake, proper water flow management is crucial for both commercial and residential properties. This is where automated backflow preventers (ABPs) play a vital role in ensuring safe drinking water. This article guides you through the comprehensive process of ABP installation, from understanding these devices’ significance to maintaining their effectiveness. Whether you’re in need of commercial backflow preventer installation or residential, this step-by-step overview ensures property owners and managers are equipped with knowledge for a successful and secure setup.”

- Understanding Backflow Preventers: Their Role and Types for Spring Lake Properties

- Preparing for Installation: What to Expect During a Commercial or Residential Backflow Preventer Job

- The Step-by-Step Guide: How Professionals Install Backflow Preventers in Spring Lake

- Maintenance and Testing: Ensuring Your Backflow Preventer Remains Effective Over Time

Understanding Backflow Preventers: Their Role and Types for Spring Lake Properties

Backflow preventers are crucial safety devices designed to stop contaminated water from flowing back into potable water supplies. In Spring Lake, whether for commercial or residential properties, their installation is not just a regulatory requirement but also a vital step in safeguarding drinking water quality. These devices play a pivotal role in preventing the backward flow of water, ensuring that any potential contaminants remain contained and do not reach the main water supply.

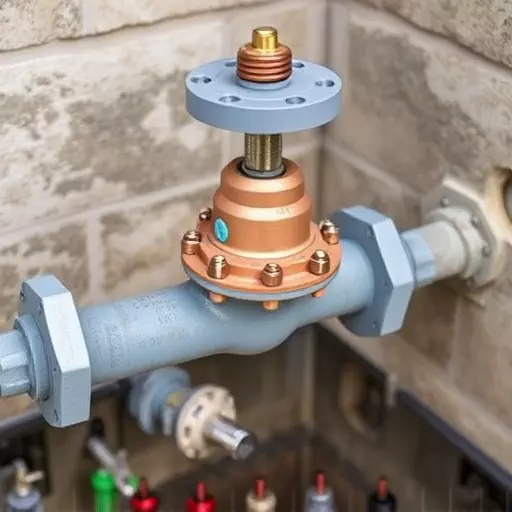

There are various types of backflow preventers available, each suited to specific applications. For instance, reduced pressure backflow preventers (RPBP) are commonly used in residential settings, offering a simple, reliable solution. In contrast, commercial backflow installations might require more sophisticated models that can handle higher pressures and flows. Understanding these options is essential for property owners and managers in Spring Lake to make informed decisions regarding their water safety and comply with local regulations, thus ensuring the integrity of the community’s water supply.

Preparing for Installation: What to Expect During a Commercial or Residential Backflow Preventer Job

Preparing for a backflow preventer installation is crucial, whether it’s for a commercial or residential property in Spring Lake. Before the experts arrive, there are several steps to anticipate and considerations to keep in mind. First, ensure all residents or business occupants are informed about the upcoming work and any necessary preparations. This may include temporary disruptions to water supply, so having alternative arrangements for essential needs is wise.

During the installation process, you can expect skilled technicians to assess the specific backflow preventer type suitable for your plumbing system. They will locate and prepare the entry points, ensuring all components are accessible. The job requires precision, as these professionals install and test the devices to meet local regulations, guaranteeing a safe water supply by preventing any potential contamination.

The Step-by-Step Guide: How Professionals Install Backflow Preventers in Spring Lake

When it comes to installing a backflow preventer in Spring Lake, professionals follow a meticulous step-by-step process to ensure safety and compliance with local regulations. The first steps involve assessing the water system and identifying the type of backflow preventer needed – be it for commercial or residential properties. This includes evaluating pressure and flow rates to select an appropriate device that can handle the specific demands of the location.

The installation itself commences with shutting off the water supply to the affected area. After preparing the pipe connections, professionals carefully install the backflow preventer, ensuring it’s securely fastened and aligned correctly. Rigorous testing is then conducted to verify its functionality. This includes pressure testing to confirm the device can withstand and regulate water pressure effectively. Only after successful tests is the water supply restored, guaranteeing a safe and reliable system.

Maintenance and Testing: Ensuring Your Backflow Preventer Remains Effective Over Time

Regular maintenance and testing are essential aspects of ensuring your backflow preventer remains effective over time, whether for commercial backflow preventer installation in Spring Lake or residential settings. It’s crucial to follow a structured schedule for inspection, cleaning, and testing to safeguard your water supply from potential contamination. Simply put, a well-maintained backflow preventer can significantly reduce the risk of harm caused by backflowing water, which could contain harmful substances like bacteria, chemicals, or even sewer content.

During maintenance, inspect the device for any signs of damage, corrosion, or leaks. Clean the backflow preventer as per the manufacturer’s guidelines to eliminate debris and contaminants that might accumulate over time. Testing should be done periodically to verify its functionality, with specific intervals recommended based on local regulations and the type of backflow preventer installed. This proactive approach to maintenance and testing not only ensures the safety of your water but also helps extend the lifespan of your backflow preventer, providing peace of mind for both commercial and residential properties in Spring Lake.