Backflow preventers are vital for safeguarding potable water sources in Spring Lake and surrounding areas from chemical plant contamination. Both commercial and residential spaces require these devices' installation to isolate contaminated water, with maintenance and tailored selection key for effectiveness. Commercial installations need expert knowledge to meet regulatory standards, while residential setups demand meticulous attention to protect local water supplies. Regular testing and maintenance are crucial for long-term protection against hazardous backflow in chemical plants, ensuring a safe distribution network. Professional backflow preventer installation services in Spring Lake cater to both commercial and residential needs, adhering to industry standards and regulations.

In the dynamic landscape of chemical manufacturing, understanding backflow prevention is paramount. This intricate process involves safeguarding plants from hazardous fluid reversal, a critical safety measure to mitigate risks and ensure operational continuity. This article explores the multifaceted aspects of backflow control, offering insights into its dangers, the indispensable role of backflow preventers, various system types for commercial and residential applications, installation guidelines, and the importance of regular maintenance. For tailored solutions, consider expert backflow preventer installation in Spring Lake for both industrial and domestic settings.

- Understanding Backflow and Its Dangers in Chemical Plants

- The Role of Backflow Preventers in Safety Measures

- Types of Backflow Preventer Systems for Commercial Applications

- Guidelines for Installing Residential Backflow Preventers

- Regular Maintenance and Testing: Ensuring Long-Term Protection

Understanding Backflow and Its Dangers in Chemical Plants

Backflow, a phenomenon where contaminated water flows backward through pipes intended for clean water supply, poses significant risks in chemical plants. This can happen due to backpressure from processes or system failures, leading to the potential introduction of harmful substances into potable water sources. In Spring Lake and beyond, commercial and residential areas alike require backflow preventer installation as a critical safety measure. These devices are designed to stop backflow, ensuring that any contaminated water remains isolated within the chemical plant’s systems.

Regular maintenance and proper selection of backflow preventers, tailored to the specific needs of each facility, are essential. Commercial backflow preventer installation demands expertise to meet regulatory standards while residential installations require a similar level of attention to safeguard local water supplies. By implementing these safety mechanisms, chemical plants can mitigate environmental hazards and protect public health.

The Role of Backflow Preventers in Safety Measures

Backflow preventers play a vital role in maintaining safety within chemical plants and facilities. These devices are critical components of any robust security system, designed to stop contaminated water from flowing back into potable or clean water sources. In the event of a breach or failure in the main supply line, backflow preventers act as a barrier, safeguarding both the water supply and the surrounding environment.

For commercial and residential properties alike, proper backflow preventer installation in Spring Lake is essential. Commercial backflow preventer installations are tailored to meet the demanding needs of industrial settings, ensuring that hazardous substances cannot reverse flow into municipal water systems. Similarly, residential installations protect homes and communities from potential contamination, underscoring the importance of these devices in everyday life.

Types of Backflow Preventer Systems for Commercial Applications

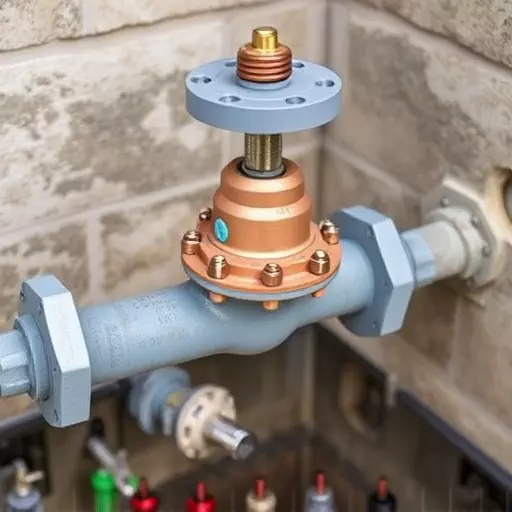

In commercial applications, especially in chemical plants, effective backflow prevention is crucial for maintaining safety and compliance. Various types of backflow preventer systems are available to suit different needs. One common and reliable option is the reduced pressure backflow preventer (RPBP). This device operates by maintaining a lower pressure on the inlet side than the outlet side, preventing contaminants from flowing back into the main supply line. RPBPs are suitable for a wide range of chemicals and are often required in locations where potential hazards exist.

Another type is the check valve assembly, which uses a one-way valve to prevent backflow. These are typically used in residential backflow preventer installation scenarios. While they may not be as complex as RPBPs, they still play a vital role in stopping contaminated water from flowing backward. The choice between these systems depends on factors such as the nature of the chemicals being handled, pressure levels, and regulatory requirements, with professional installation services like those offered in Spring Lake ensuring optimal performance and safety.

Guidelines for Installing Residential Backflow Preventers

When it comes to installing backflow preventers in residential settings, Spring Lake residents should adhere to strict guidelines to ensure safety and compliance with local regulations. The process involves careful selection of the appropriate device for the specific water system, followed by precise installation. It’s crucial to engage licensed professionals who understand the nuances of both residential plumbing systems and backflow prevention technology.

Commercial backflow preventer installation requires a different approach, catering to larger-scale operations with more complex water management needs. In these cases, specialized equipment and robust safety measures are essential. The goal is to safeguard drinking water sources from potential contamination by harmful substances used in chemical processing or other industrial activities.

Regular Maintenance and Testing: Ensuring Long-Term Protection

Regular maintenance and testing are vital components of ensuring long-term protection against hazardous backflow in chemical plants. A comprehensive maintenance schedule should include periodic inspections, cleaning, and replacement of critical components in backflow preventer systems. This proactive approach helps to identify any potential issues early on, preventing costly breakdowns and more severe accidents.

Commercial and residential backflow preventer installation require specialized expertise to ensure the system’s effectiveness. Spring Lake residents and businesses can benefit from professional services that adhere to industry standards and regulations. Regular testing, typically every 3 to 6 months, is essential to verify the backflow preventer’s integrity and functionality, guaranteeing a safe and secure chemical distribution network.