High-capacity steel racks enabled by custom CNC machining in Holland, Ohio, are transforming the packaging industry. These solutions offer improved product organization, streamlined inventory management, and optimized space utilization, reducing waste and maximizing storage capacity. CNC machining enhances product stability, security, and brand identity, leading to cost savings and improved customer satisfaction. This technology revolutionizes packaging, boosting efficiency and visual appeal in competitive markets.

High-capacity steel racks are transforming the packaging landscape in Holland, Ohio, and beyond. This article explores how CNC machining for packaging industry Holland Ohio is revolutionizing storage solutions with custom CNC-machined packaging components. We delve into the benefits of CNC machining in packaging, highlighting precision, time/cost savings, and adaptability to diverse needs. Through real-world case studies, we showcase successful implementations that underscore the profound impact these innovations have on production capacity and workflow efficiency.

- Revolutionizing Packaging with High-Capacity Steel Racks

- – The Rise of CNC Machining in the Packaging Industry

- – How Custom CNC-Machined Components Enhance Efficiency

Revolutionizing Packaging with High-Capacity Steel Racks

High-capacity steel racks are transforming the landscape of the packaging industry, particularly in Holland, Ohio, where CNC machining plays a pivotal role. By leveraging custom CNC-machined packaging components, manufacturers can significantly enhance their operations’ efficiency and effectiveness. These innovative solutions offer numerous benefits, from improved product organization to streamlined inventory management.

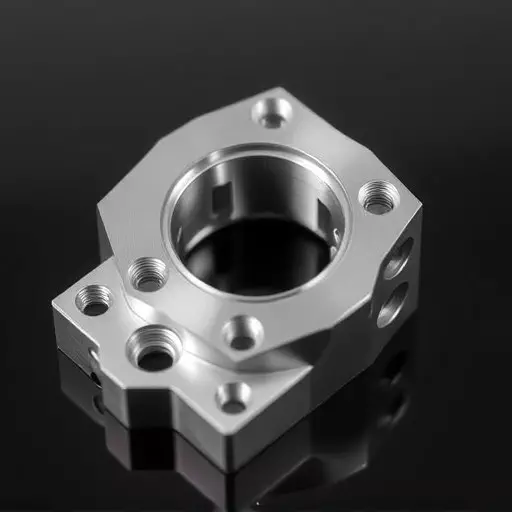

CNC machining allows for precise manufacturing of steel racks tailored to specific packaging needs. This customization ensures optimal space utilization, reducing waste and maximizing storage capacity. Moreover, the precision engineering of these racks enhances product stability and security, minimizing damage during handling and transportation. Embracing CNC machining in the packaging industry, therefore, is a game-changer, revolutionizing how businesses manage their products, ultimately contributing to cost savings and improved customer satisfaction.

– The Rise of CNC Machining in the Packaging Industry

In recent years, the packaging industry has witnessed a significant transformation with the advent and increasing popularity of CNC (Computer Numerical Control) machining. Located in Holland, Ohio, many businesses are leveraging CNC machining for packaging industry applications, leading to the creation of custom, high-precision packaging components. This innovative technology offers numerous benefits that have elevated the standards of product packaging and presentation.

CNC machining provides a range of advantages, such as enhanced speed, accuracy, and efficiency in manufacturing custom packaging solutions. It enables the production of intricate and complex designs that were once challenging or impossible to achieve with traditional methods. As a result, brands can now create unique, visually appealing, and tailored packages for their products, enhancing the overall unboxing experience for consumers. This shift towards CNC machining has not only revolutionized the way products are packaged but also set new benchmarks for brand identity and customer satisfaction in competitive markets.

– How Custom CNC-Machined Components Enhance Efficiency

In the dynamic landscape of modern packaging, efficiency is key to staying competitive. High-capacity steel racks, when combined with custom CNC-machined components, offer a powerful solution for optimising storage and handling operations. These tailored, precision-engineered parts are designed to fit perfectly within specific rack systems, enhancing overall system performance. By leveraging CNC machining techniques, manufacturers can produce complex geometry components with unparalleled accuracy and repeatability, ensuring seamless integration within the packaging industry’s stringent requirements.

Custom CNC machining for the packaging industry in Holland, Ohio, brings numerous benefits. It allows for the creation of bespoke parts that cater to unique rack configurations and specific task demands. This level of customisation results in improved productivity by reducing time spent on manual adjustments or adapting standard components. Moreover, CNC-machined packaging components offer enhanced durability, precision alignment, and consistent performance, ultimately contributing to a more streamlined and efficient workflow across various stages of the packaging process.