Revolutionizing Industrial Air Quality: High-Temperature Ventilation Solutions

Industrial facilities demand tailored ventilation solutions encompassing exhaust and supply systems…….

Industrial facilities demand tailored ventilation solutions encompassing exhaust and supply systems…….

Smoke and fume extraction systems are critical components of industrial ventilation solutions, along…….

Energy Recovery Ventilators (ERVs) are transforming industrial ventilation by recovering heat from e…….

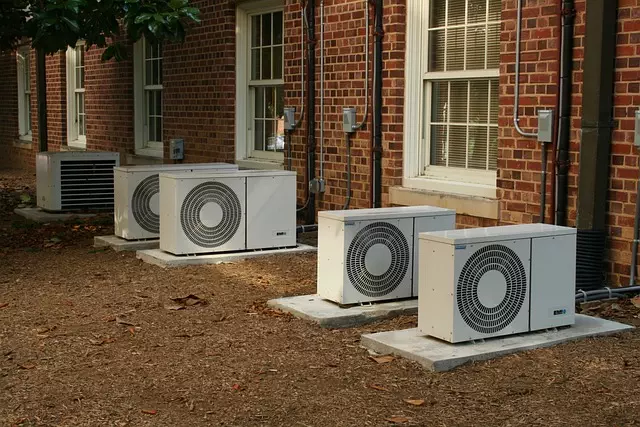

Industrial facilities face challenges in maintaining air quality, ensuring worker safety, and comply…….

In the manufacturing sector, proper ventilation is crucial for both efficiency and worker safety. Mo…….

In industrial settings, effective ventilation is crucial for worker safety, productivity, and overal…….

Implementing effective industrial ventilation solutions is crucial for creating safe, productive, an…….

In confined industrial settings, proper ventilation using industrial ventilation solutions is critic…….

Industrial ventilation solutions, combining exhaust and supply systems, are vital for maintaining ai…….