Lightweight EPP Molded Foam Packaging: Holland, Ohio’s Sustainable Solution

Lightweight EPP molded foam packaging from Holland, Ohio, is a revolutionary, eco-friendly alternati…….

Lightweight EPP molded foam packaging from Holland, Ohio, is a revolutionary, eco-friendly alternati…….

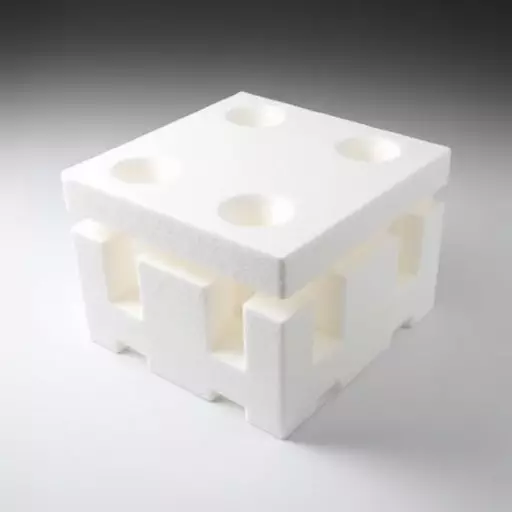

Custom EPP foam inserts made from lightweight expanded polypropylene (EPP) foam are revolutionizing…….

Expanded Polypropylene (EPP) foam packaging in Holland, Ohio, offers a lightweight yet robust soluti…….

UV-resistant expanded polypropylene (EPP) foam inserts, meticulously designed in Holland, Ohio, offe…….

Custom-molded EPP foam from Holland, Ohio, offers innovative and sustainable packaging for diverse i…….

In Holland, Ohio, Expanded Polypropylene (EPP) molded foam packaging is revolutionizing logistics an…….

Expanded Polypropylene (EPP) foam packaging, a lightweight and versatile material, is transforming i…….

Expanded Polypropylene (EPP) molded foam packaging from Holland, Ohio, offers a revolutionary soluti…….

Expanded Polypropylene (EPP) foam is a revolutionary, eco-friendly packaging material produced in Ho…….

Lightweight EPP molded foam packaging from Holland, Ohio, has transformed mobile device protection……..