CNC-cut foam inserts are custom solutions for protecting sensitive electronic devices during storage and transport. Made in Holland, Ohio with advanced CNC machining, these ESD-safe foams offer unparalleled protection against impact and static discharge, ensuring electronics remain secure and minimizing damage. Custom foam inserts tailored to shipping containers are essential for safe transportation of electronic components, reducing product damage and enhancing customer satisfaction. ESD-safe foam inserts, engineered to neutralize static charges, are crucial for industries in Holland, Ohio and beyond that rely on precise electronic components, preventing costly malfunctions caused by electrostatic discharge.

“Discover the transformative power of CNC-cut foam inserts in Holland, Ohio’s thriving electronics industry. This comprehensive guide explores the multifaceted world of protective foam solutions. From understanding the intricacies of CNC cutting to the crucial role of ESD (Electrostatic Discharge) safety, we delve into how these custom foam inserts ensure sensitive electronics are shielded during transit. Learn about their diverse applications and the importance of selecting the right anti-static, high-quality foam for optimal protection.”

- Understanding CNC-Cut Foam Inserts: A Comprehensive Overview

- The Role of Protective Foam Inserts in Electronics Packaging

- Customization: Creating Anti-Static Foam for Specific Electronics Needs

- ESD Safety: Why Electrostatic Discharge Protection is Crucial

- Applications of CNC-Cut Foam Inserts in Holland, Ohio's Electronics Industry

- Choosing the Right Material: Properties of High-Quality Anti-Static Foam

Understanding CNC-Cut Foam Inserts: A Comprehensive Overview

CNC-cut foam inserts are specialized components designed to offer protection and support for sensitive electronic devices. These custom foam solutions, often made from ESD (Electrostatic Discharge)-safe materials, play a vital role in maintaining the integrity and safety of electronics during storage and transportation. In industries where precision and protection matter most, such as manufacturing facilities in Holland, Ohio, protective foam inserts are indispensable.

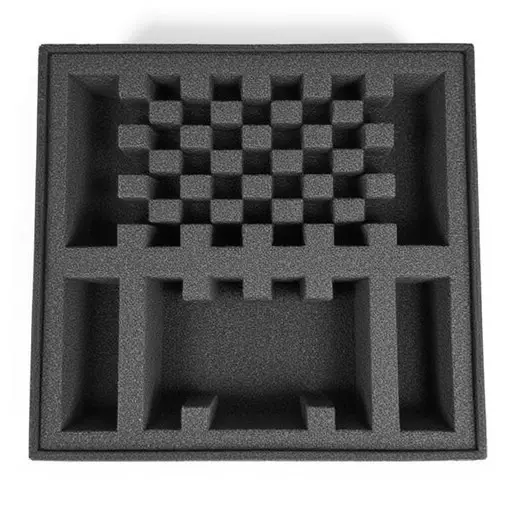

These innovative inserts are meticulously crafted using Computer Numerical Control (CNC) machines, ensuring precise dimensions and intricate designs tailored to specific electronic components. Whether for anti-static protection or impact absorption, CNC machining allows for the creation of unique shapes and structures that traditional foam cuts cannot match. This level of customization ensures electronics remain secure, minimizing damage and improving overall product quality.

The Role of Protective Foam Inserts in Electronics Packaging

Protective foam inserts play a crucial role in the packaging and transportation of electronic components, ensuring their safe arrival at their destination. These custom-cut foam inserts are designed to fit snugly within shipping containers, providing a cushioning effect that protects sensitive electronics from potential damage during transit. By utilizing ESD-safe (Electrostatic Discharge) foam, manufacturers can further safeguard delicate gear against the risk of static electricity discharge, which could cause costly malfunctions or even render devices useless.

For businesses in Holland, Ohio, and beyond, investing in high-quality custom foam inserts offers significant advantages. Not only do they reduce the likelihood of product damage, but they also contribute to maintaining the integrity of electronics packaging. This is particularly important for companies specializing in electronic components, ensuring their products reach customers in optimal condition, thereby enhancing customer satisfaction and loyalty.

Customization: Creating Anti-Static Foam for Specific Electronics Needs

CNC-cut foam inserts offer unparalleled customization options, allowing manufacturers to create protective foam solutions tailored to specific electronic components and assemblies. By employing advanced CNC machinery, precise shapes and intricate details can be achieved, ensuring optimal fit and functionality. This level of customization is particularly vital for electronics assembly, where different parts require unique protection against damage, shock, and static discharge.

One specialized application is the development of anti-static foam inserts, designed to meet the stringent ESD (Electrostatic Discharge) safety standards crucial for sensitive electronic devices. These custom foam solutions can be crafted from materials that effectively dissipate static electricity, safeguarding delicate components from potential harm. Manufacturers in Holland, Ohio, and beyond leverage this technology to produce protective foam inserts for electronics, catering to diverse industry needs with precision and efficiency.

ESD Safety: Why Electrostatic Discharge Protection is Crucial

In the manufacturing and assembly of electronic components, Electrostatic Discharge (ESD) safety is a critical concern that cannot be overlooked. When handling sensitive electronics, even minor static shocks can cause significant damage or render devices useless. This is particularly true for intricate devices packed with delicate parts inside protective foam inserts, as commonly used in various industries, including automotive and aerospace, based in Holland, Ohio. Custom foam inserts designed to protect these components must incorporate anti-static properties to mitigate the risks associated with ESD events.

ESD-safe foam inserts are engineered to neutralize static charges effectively while safeguarding electronic parts from sudden electrical discharges. This is crucial for maintaining product integrity and performance, especially during storage, transportation, or assembly processes. By integrating anti-static agents into their structure, these foam inserts ensure that any accumulated static electricity dissipates safely, preventing potential damage to sensitive electronics. Such precautions are vital for industries relying on precise, reliable electronic components, underscoring the importance of choosing ESD-safe protective foam inserts for electronics storage and transportation in Holland, Ohio, and beyond.

Applications of CNC-Cut Foam Inserts in Holland, Ohio's Electronics Industry

In Holland, Ohio’s thriving electronics industry, CNC-cut foam inserts play a vital role in ensuring the safe and secure packaging of sensitive electronic components. These custom foam inserts are meticulously designed to fit various equipment and enclosures, providing optimal protection during transportation and storage. One of their primary applications is in the creation of protective foam inserts for electronics, specifically tailored to meet the unique requirements of each client.

The demand for ESD-safe (Electrostatic Discharge) foam inserts has significantly grown within the industry. Anti-static foam for electronics is a specialized product that prevents the buildup and discharge of static electricity, which can cause severe damage to delicate electronic parts. CNC machining allows for the precise cutting of these foam materials, resulting in high-quality custom foam inserts that not only safeguard equipment but also adhere to strict quality control standards.

Choosing the Right Material: Properties of High-Quality Anti-Static Foam

When selecting materials for protective foam inserts designed for electronics in Holland, Ohio, or beyond, choosing anti-static foam is paramount. High-quality ESD (Electrostatic Discharge) safe foam inserts are crucial to safeguarding sensitive electronic components from damage caused by static electricity buildup. These specialized foams possess unique properties that ensure stability, durability, and a consistent static dissipative performance.

Key characteristics of top-tier anti-static foam include low electrical resistance, ensuring any built-up charge is safely discharged, and superior flexibility for conforming to various electronic devices’ shapes and sizes. Customizable foam inserts allow for precise protection, catering to the unique requirements of diverse electronics, from intricate gadgets to large industrial equipment. This level of customization, combined with the inherent ESD safety features of these foams, makes them indispensable in industries where static electricity can cause catastrophic failures or damage to sensitive components.