CNC machining is transforming protective foam insert manufacturing in Holland, Ohio, offering tailored solutions for electronic component packaging. Advanced computer-controlled machines create custom foams with precise dimensions and intricate geometries, ideal for anti-static or ESD-safe packaging. These specialized foams safeguard electronics from damage during shipping by mitigating shocks, vibrations, and static discharge. Custom foam inserts are essential for secure transportation of sensitive components in competitive markets, enhancing product integrity, reducing costs, and improving retail appeal. Key terms: protective foam inserts for electronics Holland Ohio, custom foam inserts, ESD-safe foam, anti-static foam for electronics.

“Discover how CNC machining is revolutionizing custom packaging solutions, especially for the electronics industry. This article explores the intricate world of precision engineering, focusing on protective foam inserts tailored to sensitive components. We delve into the benefits of custom foam, ensuring device integrity with ESD-safe and anti-static foams. From understanding CNC machining to a real-world case study of a Holland, Ohio-based electronics company, read on to learn how this technology enhances product protection and packaging efficiency.”

- Understanding CNC Machining for Custom Packaging

- The Role of Protective Foam Inserts in Electronics Packaging

- Benefits of Custom Foam Inserts for Sensitive Components

- ESD-Safe and Anti-Static Foams: Ensuring Device Integrity

- Case Study: Implementing CNC Machining for a Holland, Ohio-Based Electronics Company

Understanding CNC Machining for Custom Packaging

CNC machining offers unparalleled precision and customization for creating protective foam inserts tailored to specific product needs, such as those for electronics in Holland, Ohio. By utilizing advanced computer-controlled machines, manufacturers can produce complex geometries and precise dimensions that are ideal for designing anti-static or ESD-safe foam inserts, ensuring the safe transport of sensitive electronic components.

These custom foam solutions are designed to fit perfectly within packaging, safeguarding delicate items from damage during shipping and handling. The versatility of CNC machining allows for the creation of diverse materials, including specialized foams that provide superior protection against shocks, vibrations, and static discharge—crucial factors in maintaining the integrity of electronics.

The Role of Protective Foam Inserts in Electronics Packaging

Protective foam inserts play a vital role in ensuring the safe transportation and handling of electronic components. In the competitive market for custom packaging solutions, especially in regions like Holland, Ohio, manufacturers are seeking innovative ways to safeguard delicate electronics from potential damage during transit. Custom foam inserts are designed to fill the voids within packages, offering shock absorption and impact protection. This is particularly crucial for sensitive devices that require meticulous handling due to their intricate nature and potential for high value.

One of the key considerations in choosing protective foam inserts for electronics packaging is static discharge prevention. ESD-safe (Electrostatic Discharge) foam inserts are specifically engineered to mitigate the risk of electrostatic damage, which can cause irreversible harm to electronic components. These inserts are often made from materials that have low dielectric constants and excellent electrical conductivity, ensuring that any built-up static charges dissipate safely. This is especially important for industries dealing in high-tech electronics, where anti-static foam packaging can be a game-changer in maintaining product integrity.

Benefits of Custom Foam Inserts for Sensitive Components

Custom foam inserts offer unparalleled protection for sensitive electronic components during transportation and storage. These innovative solutions are especially valuable in industries where static electricity discharge (ESD) can damage delicate parts, such as electronics manufacturing in Holland, Ohio. ESD-safe foam inserts are designed to minimize the risk of electrostatic discharge by providing a safe, conductive path for any accumulated charge, thus safeguarding components from potential harm.

The benefits extend beyond ESD protection. Custom foam inserts can be tailored to fit specific component sizes and shapes, ensuring secure placement and minimizing movement during transit. This not only reduces the likelihood of damage but also cuts down on packaging costs by optimizing space utilization. Furthermore, these inserts enhance product presentation and retail appeal when incorporated into custom packaging solutions.

ESD-Safe and Anti-Static Foams: Ensuring Device Integrity

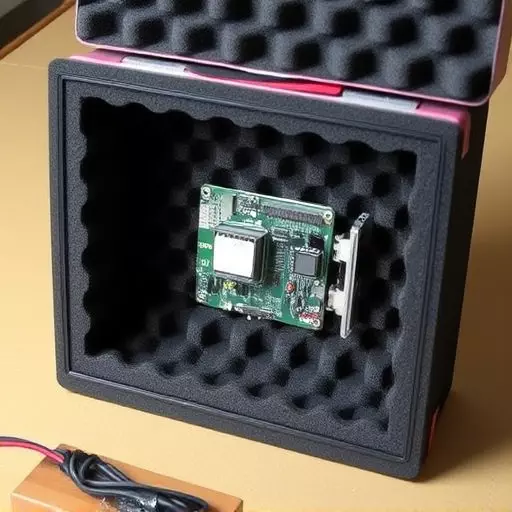

ESD-Safe and anti-static foams play a critical role in CNC machining for custom packaging solutions, especially when it comes to protecting delicate electronics. These specialized foams are designed to prevent electrostatic discharge (ESD), which can cause significant damage to sensitive components. In environments where static electricity buildup is a concern, like manufacturing facilities or storage warehouses, ESD-safe foam inserts for electronics Holland Ohio are essential. They ensure the integrity and functionality of electronic devices by creating a conductive path that safely dissipates any accumulated charge.

Custom foam inserts offer more than just protection; they also enhance the overall packaging design. By tailoring the shape, size, and density of the foam to fit specific device requirements, these inserts provide secure holding and minimize movement during transportation. This reduces the risk of internal component damage or misalignment, ensuring that electronics reach their destination in optimal condition. Whether for protecting intricate circuit boards, delicate sensors, or complex assembly components, ESD-safe and anti-static foams are indispensable elements in crafting effective custom packaging solutions.

Case Study: Implementing CNC Machining for a Holland, Ohio-Based Electronics Company

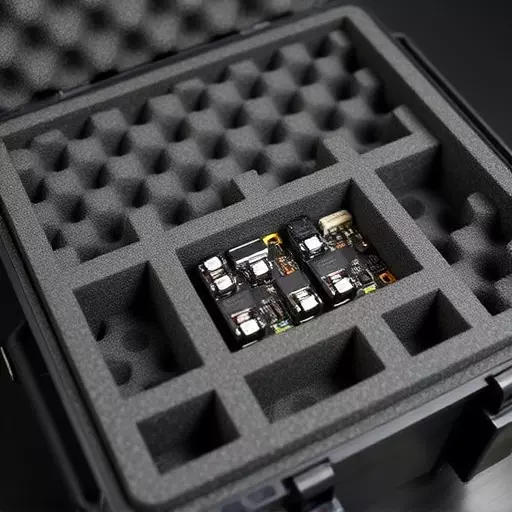

A Holland, Ohio-based electronics company faced a challenge in meeting the unique packaging needs of their specialized products. They required protective foam inserts designed to safely accommodate sensitive electronic components, ensuring no damage during transit. Traditional methods proved insufficient, highlighting the need for a tailored solution. This is where CNC machining stepped in as a game-changer.

By implementing CNC machining, the company was able to create custom foam inserts that perfectly fit their electronics’ dimensions. These ESD-safe (Electrostatic Discharge) foam inserts, crafted with anti-static materials, provided an ideal protective layer for the delicate components. The precision of CNC machining ensured no static buildup, a significant concern in the electronic industry. This innovative approach revolutionized their packaging process, leading to increased product integrity and customer satisfaction.