CNC machining has revolutionized aerospace manufacturing, particularly in securing sensitive electronic equipment. Holland, Ohio, stands out with specialized manufacturers producing custom ESD-safe (Electrostatic Discharge) foam inserts. These inserts offer unparalleled shock absorption, isolate vibration, and provide anti-static protection, ensuring the safe transport and storage of high-tech components. By leveraging CNC machining, aerospace companies can efficiently produce these tailored solutions, enhancing supply chain management and safeguarding valuable electronics. ESD-safe foam inserts from Holland manufacturers are vital for protecting sensitive electronic parts during shipping, preventing electrostatic damage, and meeting stringent industry standards.

“The aerospace industry demands precision and innovation in packaging to safeguard sensitive components during transit. CNC machining has emerged as a game-changer, offering tailored solutions for complex packaging requirements. This article explores the intricate world of CNC machining for aerospace packaging, highlighting its benefits through protective foam inserts. From custom designs to ESD-safe foams, we delve into how these innovative materials protect electronics in Holland, Ohio, and beyond, ensuring data integrity and component safety.”

- Understanding CNC Machining for Aerospace Packaging

- The Role of Protective Foam Inserts in Electronics Storage

- Custom Foam Inserts: Tailoring Solutions for Complex Parts

- ESD-Safe Foam Inserts: Ensuring Data Integrity in Electronics Shipping

- Benefits of Anti-Static Foam for Sensitive Electronic Components

- Case Study: Holland, Ohio's Aerospace Packaging Innovation

- Future Trends in CNC Machining for the Aerospace Industry

Understanding CNC Machining for Aerospace Packaging

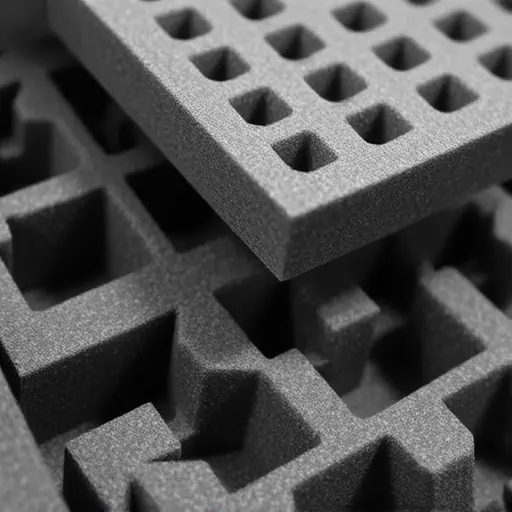

CNC machining plays a pivotal role in shaping and producing precise components for the aerospace industry, particularly when it comes to packaging sensitive electronic equipment. This advanced manufacturing process allows for the creation of intricate protective foam inserts tailored to specific needs. These custom foam inserts are designed to ensure the safe transportation of electronics by providing shock absorption, vibration isolation, and anti-static protection—all crucial elements for maintaining the integrity of high-tech components.

In Holland, Ohio, manufacturers specialize in crafting ESD-safe (Electrostatic Discharge) foam inserts that safeguard sensitive electronics from potential damage. These custom solutions are meticulously engineered to fit various packaging requirements, ensuring electronics remain secure during transit and storage. By leveraging CNC machining, aerospace companies can benefit from efficient production of anti-static foam for electronics, revolutionizing the way they protect valuable assets in their supply chain.

The Role of Protective Foam Inserts in Electronics Storage

Protective foam inserts play a pivotal role in ensuring the safe storage and transportation of electronic components, especially in the aerospace industry where precision and reliability are paramount. These custom-made inserts are designed to fit snugly within packaging, safeguarding delicate electronics from physical damage during transit. By utilizing ESD-safe (Electrostatic Discharge) foam, manufacturers can mitigate the risk of electrostatic damage, a common issue with electronic components. This anti-static foam for electronics acts as a buffer, preventing any harmful static electricity from accumulating and potentially destroying sensitive parts.

With their ability to conform to intricate shapes and dimensions, custom foam inserts offer unparalleled protection. In environments like Holland, Ohio, where aerospace packaging is a significant industry, these specialized inserts are crafted to meet specific requirements. They not only provide shock absorption but also prevent the movement of components inside the package, ensuring they arrive at their destination in pristine condition.

Custom Foam Inserts: Tailoring Solutions for Complex Parts

In the aerospace industry, where every component must meet stringent standards and specifications, protective foam inserts have become an indispensable tool for ensuring the safe transport of delicate parts, especially electronics. These custom foam inserts are meticulously designed to fit complex shapes and sizes, offering a tailored solution for challenging packaging needs. By utilizing advanced CNC machining techniques, manufacturers can produce ESD-safe (Electrostatic Discharge) foam inserts that safeguard sensitive electronic components from potential damage during transit.

Holland, Ohio, has emerged as a hub for such innovative solutions, with local manufacturers specializing in custom foam inserts. Their expertise lies in creating anti-static foam for electronics, which not only provides cushioning but also neutralizes static electricity buildup—a significant concern when handling and transporting electronic devices. This localized capability allows aerospace companies to benefit from precise, cost-effective packaging solutions tailored to their unique requirements.

ESD-Safe Foam Inserts: Ensuring Data Integrity in Electronics Shipping

ESD-Safe Foam Inserts play a pivotal role in safeguarding sensitive electronic components during shipping. These specialized protective foam inserts, meticulously designed and custom-made for various electronic packaging requirements, are crucial in maintaining data integrity. The primary concern with electronics lies in preventing Electrostatic Discharge (ESD), which can cause irreversible damage to delicate circuitry. Anti-static foam materials used in these inserts effectively dissipate static electricity, creating a safe environment for the components during transit.

Manufacturers in Holland, Ohio, have recognized this need and pioneered custom foam insert solutions tailored to specific electronic packaging challenges. By utilizing advanced CNC machining techniques, they produce ESD-Safe Foam Inserts that perfectly accommodate unique product dimensions. This precision not only ensures secure placement of electronics but also minimizes the risk of damage caused by improper cushioning or shifting during shipping—a vital consideration in today’s fast-paced electronics industry.

Benefits of Anti-Static Foam for Sensitive Electronic Components

In the aerospace industry, where precision and safety are paramount, protective foam inserts play a vital role in packaging sensitive electronic components. Custom foam inserts, meticulously designed for specific part dimensions, offer more than just a physical barrier; they ensure the delicate electronics remain secure during transit and storage. One such advanced solution is anti-static foam, an innovative material that goes beyond standard protective measures.

Anti-static foam for electronics, often found in packaging from Holland, Ohio, companies specializing in custom foam inserts, provides an esd-safe (Electrostatic Discharge) environment. This property is crucial for protecting sensitive components from harmful static electricity buildup. By incorporating anti-static agents into the foam, these specialized inserts minimize the risk of electrostatic damage, ensuring the integrity and functionality of the electronic parts throughout their supply chain journey.

Case Study: Holland, Ohio's Aerospace Packaging Innovation

In Holland, Ohio, a pioneering aerospace packaging innovation has taken center stage, revolutionizing the way delicate electronic components are protected during transit. This case study highlights the success of a local manufacturer who specialized in creating custom foam inserts tailored to the unique needs of the aerospace industry. By developing protective foam inserts for electronics in Holland, Ohio, they addressed a significant challenge faced by aerospace companies: ensuring the safe transportation of sensitive equipment.

These custom foam inserts are designed with precision and an understanding of electrostatic discharge (ESD) sensitivity. The ESD-safe foam inserts are crafted to prevent damaging static electricity buildup, a critical factor for protecting high-tech electronics. By utilizing specialized materials, the Holland-based manufacturer produced anti-static foam for electronics that not only cushions and stabilizes components but also maintains a static-free environment, ensuring the integrity of sensitive parts during their journey from manufacturing to installation in aircraft.

Future Trends in CNC Machining for the Aerospace Industry

The future of CNC machining in the aerospace industry looks promising, with advancements pushing the boundaries of precision and efficiency. One key trend is the increasing demand for customized protective solutions, such as anti-static and ESD-safe foam inserts designed to safeguard delicate electronics components during transport and storage. Companies like those offering protective foam inserts for electronics Holland Ohio are at the forefront of this shift, developing innovative custom foam inserts tailored to specific part requirements.

These specialized foams play a crucial role in mitigating static electricity build-up, which can damage sensitive electronic parts. With the aerospace industry’s relentless pursuit of lighter, more compact designs, the need for lightweight yet robust anti-static packaging solutions is on the rise. CNC machining technology will continue to evolve, enabling the creation of intricate foam structures that not only protect but also optimize space utilization within aircraft components, contributing to overall design efficiency and performance.