CNC machining is transforming packaging prototype development, especially for intricate and custom designs, by enabling precise creation of complex shapes from various materials. Companies in Holland, Ohio, utilize CNC machining to produce high-quality protective foam inserts tailored to specific product dimensions and protection needs, ensuring consistent quality and meeting exacting standards. ESD-safe and anti-static foams are crucial for protecting sensitive electronic components, as today's shrinking yet complex electronics are more susceptible to electrostatic discharge (ESD) damage during handling and transportation. Custom foam inserts, designed specifically for these needs, maintain product integrity by cushioning parts against shocks, vibrations, and impacts.

“Unleashing Innovation in Packaging: CNC Machining for Prototyping

In the realm of product development, creating robust packaging prototypes is paramount. This article explores how Computer Numerical Control (CNC) machining revolutionizes this process, particularly for electronic components. We delve into the benefits of custom foam inserts, which offer unparalleled protection against damage during transit. With a focus on ESD-safe and anti-static foams, we uncover material solutions tailored to sensitive electronics, ensuring product integrity. Discover how these advanced packaging techniques, centered around protective foam inserts for electronics in Holland, Ohio, are transforming the industry.”

- Understanding CNC Machining for Packaging Prototypes

- Benefits of Custom Foam Inserts in Electronics Protection

- Material Considerations: ESD-Safe and Anti-Static Foams

Understanding CNC Machining for Packaging Prototypes

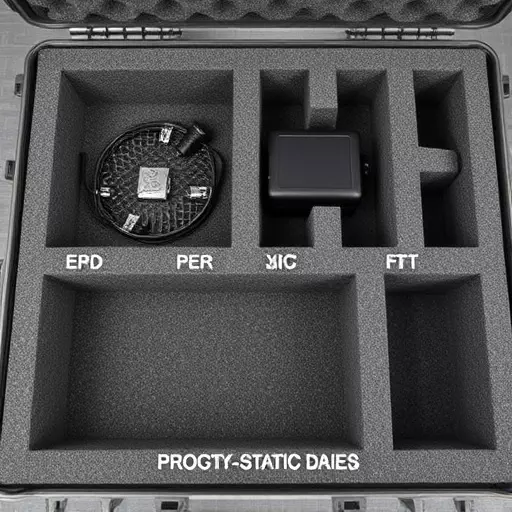

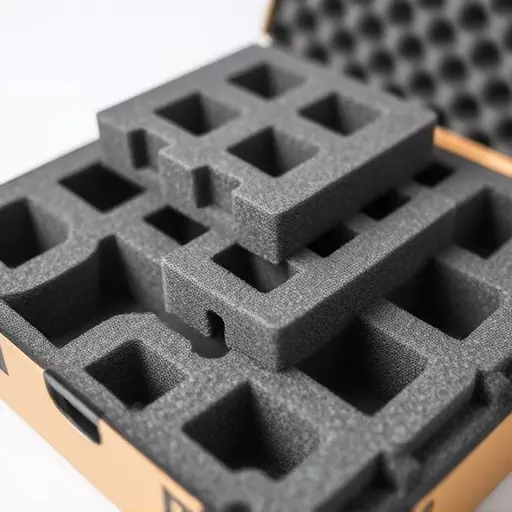

CNC machining is a revolutionary process transforming packaging prototype development, especially for intricate and custom designs. This advanced manufacturing technique allows for the creation of precise, complex shapes from a wide range of materials, making it ideal for crafting specialized protective foam inserts. For instance, companies in Holland, Ohio, offering services like custom foam inserts, ESD-safe (electrostatic discharge) foam for electronics, and anti-static foam, leverage CNC machining to produce high-quality packaging solutions.

By programming CNC machines with detailed designs, these businesses can quickly manufacture foam inserts tailored to specific product dimensions and protection needs. This level of customization ensures sensitive electronic components are securely nestled within protective foam, minimizing movement and potential damage during transportation. The precision of CNC machining also guarantees consistent quality, ensuring each prototype or production run meets exacting standards.

Benefits of Custom Foam Inserts in Electronics Protection

Custom Foam Inserts offer a multitude of benefits when it comes to protecting electronics during packaging and transportation. One of the key advantages is their ability to provide precise, tailored protection for complex electronic components. These inserts are designed to fit perfectly into packaging, ensuring that sensitive parts are securely cushioned against shocks, vibrations, and impacts. This level of customization means that delicate electronics can be handled with extra care, reducing the risk of damage during transit.

Additionally, ESD-safe (Electrostatic Discharge) foam inserts are a specialty within this realm. These custom solutions employ anti-static materials that safeguard sensitive electronic devices from potentially destructive static electricity build-up. By incorporating these protective measures, manufacturers can significantly lower the likelihood of electrostatic damage, ensuring the integrity and functionality of their products during distribution.

Material Considerations: ESD-Safe and Anti-Static Foams

When designing packaging prototypes, especially for sensitive electronic components, material considerations are paramount. One crucial aspect to keep in mind is using ESD-safe and anti-static foams. These specialized materials play a vital role in protecting delicate electronics from electrostatic discharge (ESD), which can cause significant damage during handling and transportation. Custom foam inserts, tailored to fit the specific dimensions of your packaging, offer an effective solution.

In the world of electronic packaging, protective foam inserts for electronics Holland Ohio are not just a convenience; they are an essential component in ensuring product integrity. Anti-static foams, designed to dissipate static electricity safely, prevent the buildup of charges that can interfere with sensitive components. This is particularly important as today’s electronics continue to shrink in size while increasing in complexity, making them ever more susceptible to ESD damage.