CNC machining is transforming POS packaging in Holland, Ohio's electronics manufacturing sector by creating precise custom foam inserts. These inserts, often ESD-safe (Electrostatic Discharge) foam, protect sensitive electronic components during transit, ensuring optimal shock absorption and secure placement. By offering enhanced protection against damage, these custom foam solutions are crucial for maintaining product integrity and quality in the local industry.

“Discover the revolution in point-of-sale (POS) packaging with CNC machining. This comprehensive guide delves into the intricacies of CNC technology and its transformative impact on the industry. From understanding the process to exploring its advantages, we uncover how custom foam inserts play a pivotal role in protecting electronics.

Learn about protective foam solutions tailored for delicate electronic components, including ESD-safe and anti-static materials. We focus on the specific needs of businesses in Holland, Ohio, showcasing how CNC machining enhances packaging for local electronics manufacturers.”

- Understanding CNC Machining for POS Packaging: A Comprehensive Guide

- The Role of Protective Foam Inserts in Electronics Packaging

- Customization at its Finest: Creating Unique Foam Inserts for Specific Needs

- ESD-Safe and Anti-Static Materials: Protecting Delicate Electronics

- Exploring the Benefits of CNC Machining for Electronics Packaging in Holland, Ohio

Understanding CNC Machining for POS Packaging: A Comprehensive Guide

CNC machining is revolutionizing point-of-sale (POS) packaging, offering unparalleled precision and customization for a variety of industries, including electronics manufacturing in Holland, Ohio. By utilizing computer numerical control (CNC) machines, manufacturers can create complex geometric shapes and precise dimensions with ease, ensuring optimal product protection during transit. This advanced technology is particularly beneficial when it comes to protective foam inserts designed for delicate electronic components.

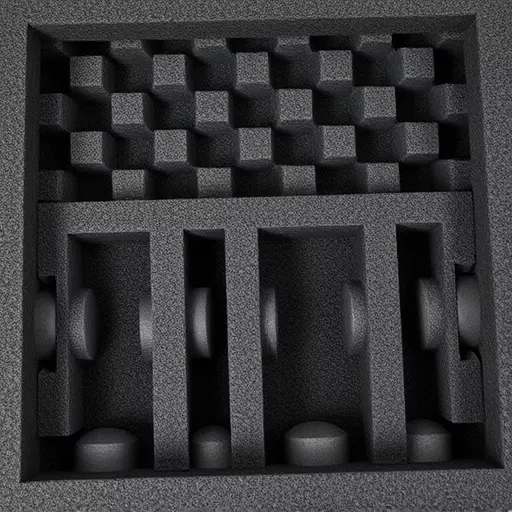

Custom foam inserts play a crucial role in safeguarding sensitive electronics from damage during shipping and handling. ESD-safe (Electrostatic Discharge) foam is a specialized material that prevents harmful static electricity build-up, a significant concern in the electronics industry. These custom-cut foam pieces not only provide shock absorption but also conform to the shape of various electronic devices, ensuring secure placement and minimizing movement inside packaging. With CNC machining, manufacturers can produce these anti-static foam inserts with exacting accuracy, catering to unique product requirements and contributing to a robust POS packaging system.

The Role of Protective Foam Inserts in Electronics Packaging

Protective foam inserts play a crucial role in ensuring the safe transportation and storage of electronic components, especially within point-of-sale packaging. These custom foam solutions are designed to cater to the specific needs of the electronics industry, offering enhanced protection against damage during handling and distribution. By utilizing ESD-safe (Electrostatic Discharge) foam inserts, manufacturers can mitigate the risk of electrostatic discharge, a significant concern in the sensitive world of electronics. This is particularly relevant for devices assembled in areas with high ESD risks or those requiring anti-static measures to prevent component damage.

The custom nature of these foam inserts allows for precise fitting within various packaging configurations, ensuring that electronic parts are snugly secured and prevented from shifting during transit. This level of customization not only guarantees the safety of delicate electronics but also optimizes space utilization, a key factor in efficient point-of-sale packaging designs. With their ability to provide both structural support and shock absorption, protective foam inserts for electronics in Holland, Ohio, and beyond, have become indispensable tools in maintaining product integrity and quality.

Customization at its Finest: Creating Unique Foam Inserts for Specific Needs

CNC machining offers unparalleled customization options when it comes to creating protective foam inserts for electronics in Holland, Ohio. This advanced manufacturing process enables precise cutting and shaping of foam materials to fit specific product dimensions and requirements. Custom foam inserts are a game-changer for packaging electronics, ensuring delicate components are securely nestled during transportation.

For instance, ESD (Electrostatic Discharge) safe foam inserts are crucial for protecting sensitive electronic devices from static electricity. These specialized inserts are meticulously designed to accommodate various gadgets, providing an anti-static barrier that safeguards against damaging sparks. By leveraging CNC machining, manufacturers can produce custom foam inserts with intricate details and exact specifications, catering to the unique needs of different electronics and enhancing overall product protection.

ESD-Safe and Anti-Static Materials: Protecting Delicate Electronics

ESD-Safe and Anti-Static Materials play a pivotal role in CNC machining for point-of-sale packaging, especially when handling delicate electronic components. In the dynamic landscape of retail, where products need to be not just visually appealing but also functional, the safety of sensitive electronics is paramount. Custom foam inserts, available in Holland, Ohio, offer an effective solution by acting as a protective barrier against Electrostatic Discharge (ESD). These ESD-safe and anti-static foam materials ensure that components like circuit boards, sensors, and microprocessors remain intact during transportation and handling.

By incorporating these specialized foams into packaging designs, manufacturers can prevent static electricity buildup, which could cause damage to the electronics. Customized to fit specific product dimensions, these protective foam inserts for electronics provide a snug yet safe environment, minimizing movement within the package. This proactive approach not only reduces the risk of functional failures but also upholds quality standards, ensuring that point-of-sale packaging delivers products in pristine condition to end users.

Exploring the Benefits of CNC Machining for Electronics Packaging in Holland, Ohio

CNC machining is transforming the landscape of packaging in Holland, Ohio, particularly within the electronics industry. One of its significant advantages lies in the creation of tailored protective foam inserts for electronic devices. These custom foam inserts are meticulously designed to fit various equipment, ensuring secure and safe transportation during distribution. With precision cutting and shaping capabilities, CNC machines produce anti-static foam that prevents damage caused by electrostatic discharge (ESD), a common concern in electronics packaging.

For businesses in Holland, Ohio, seeking reliable solutions for their point-of-sale packaging, CNC machining offers numerous benefits. It enables the production of unique and specialized protective materials, such as ESD-safe foam inserts, tailored to meet specific product requirements. This level of customization ensures that delicate electronic components arrive at their destination in pristine condition, reducing potential losses due to mishandling or damage during transit.