CNC machining is revolutionizing the manufacturing of wind turbine components in Holland, Ohio, offering unparalleled precision and efficiency. Custom CNC-machined packaging components for wind turbines showcase enhanced structural integrity, precise dimensions, efficient storage/transportation, improved productivity, reduced material waste, and intricate designs. These benefits make CNC machining a vital asset for the renewable energy industry, meeting the growing demand for specialized steel racks to store and organize turbine components with superior quality standards.

The wind energy sector’s rapid growth demands efficient solutions for manufacturing, storing, and transporting its intricate parts. This article explores how steel racks, a critical component manufactured using CNC machining, are revolutionizing the wind turbine industry. We delve into the precision-milling technology behind these custom parts, highlighting their benefits for supply chain optimization. From reduced lead times to enhanced environmental resilience, CNC-machined packaging components in Holland, Ohio, are setting new standards in wind energy manufacturing, ensuring projects meet stringent deadlines and performance requirements.

- The Role of CNC Machining in Wind Turbine Component Manufacturing

- – Exploring the demand for precise and custom parts

The Role of CNC Machining in Wind Turbine Component Manufacturing

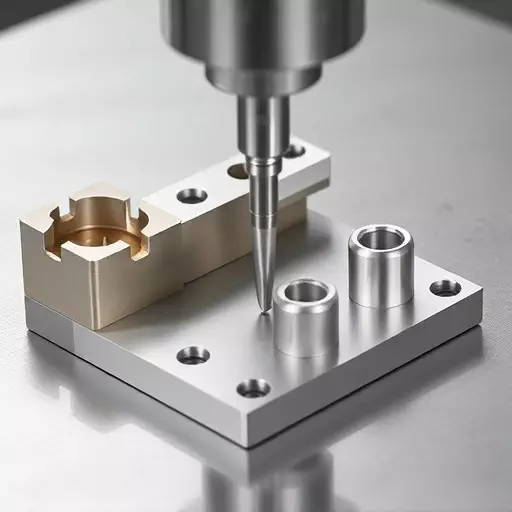

CNC machining plays a pivotal role in the manufacturing process of wind turbine components, offering precision and efficiency that are crucial for this industry. In the context of wind turbine part production, CNC (Computer Numerical Control) machining is used to create complex geometric shapes with tight tolerances from various materials, such as steel. This advanced manufacturing technique ensures the consistent production of high-quality, custom-designed parts, which are essential for the optimal performance and reliability of wind turbines.

For instance, in Holland, Ohio’s packaging industry, CNC machining has evolved beyond traditional applications to cater to the specialized needs of wind energy components. Custom CNC-machined packaging components designed for wind turbine parts exhibit enhanced structural integrity and precise dimensions, facilitating efficient storage and transportation. The benefits of CNC machining in this sector include improved productivity, reduced material waste, and the ability to accommodate intricate designs—all contributing to the overall advancement of wind turbine technology.

In today’s competitive market, the packaging industry is constantly seeking innovative solutions to enhance efficiency and product quality. One such game-changer is the adoption of CNC machining for custom cnc-machined packaging components. This advanced manufacturing process offers unparalleled precision and speed, enabling the production of complex and tailored parts for various applications, including steel racks designed for wind turbine parts. By leveraging CNC machining, manufacturers in Holland, Ohio, and beyond can streamline their production lines, reduce waste, and create packaging solutions that meet the exacting standards of demanding industries like renewable energy.

The benefits of CNC machining in packaging are multifaceted. It allows for highly customized designs, ensuring each component is tailored to specific product needs. This precision engineering results in improved product protection during transportation, reducing damage and returns. Moreover, CNC machining offers cost-effectiveness through efficient material utilization and faster production times. With its ability to handle intricate details, this technology revolutionizes packaging design, making it a vital asset for businesses aiming to stay ahead in the competitive landscape of industries like wind energy, where reliable and robust packaging is essential for efficient supply chain management.

– Exploring the demand for precise and custom parts

In today’s competitive wind energy market, there’s a growing demand for precise and custom parts to meet the unique challenges of turbine manufacturing. Steel racks, specifically designed for storing and organizing wind turbine components, are no exception. These specialized structures require intricate design and fabrication, pushing the boundaries of traditional manufacturing methods. Enter CNC machining, a game-changer in the packaging industry, not just in Holland, Ohio, but globally.

CNC machining offers unparalleled precision and customization, making it ideal for creating custom cnc-machined packaging components tailored to specific turbine part requirements. The benefits are vast: enhanced structural integrity due to precise dimensions, improved efficiency through streamlined production, and reduced material waste. This advanced technology ensures that every rack is engineered to withstand the demanding environments of wind turbine installations, contributing to safer, more reliable operations.