Automotive foam inserts, custom-made to fit specific vehicle parts and protect them during transit, are a game-changer in the logistics industry. These advanced foams, showcased by a Holland, Ohio-based transport company, offer superior shock and impact resistance compared to traditional packing materials, ensuring the safe arrival of fragile automotive components. Customization is key, allowing precise fitting while preventing damage from vibrations and impacts, especially for unique part shapes and sizes. By sourcing from reputable suppliers and installing them correctly, businesses in Holland can enhance their shipping security, making them a valuable asset in the bustling automotive sector.

“In the realm of automotive safety and shipping solutions, custom automotive foam inserts play a pivotal role. This comprehensive guide explores the multifaceted benefits of these innovative insulators, particularly in Holland, Ohio. From understanding the intricate design of foam inserts for airbags to their crucial role in enhancing shipment security, we delve into how these specialized materials safeguard fragile automotive parts. Learn why choosing foam inserts is a game-changer for efficient and secure transportation.”

- Understanding Foam Inserts for Airbags: A Comprehensive Overview

- The Role of Custom Automotive Foam Inserts in Safety and Protection

- Why Choose Foam Inserts for Fragile Automotive Parts?

- How to Source and Install Automotive Foam Inserts in Holland, Ohio

- Unlocking the Benefits: Enhancing Shipment Security with Foam Inserts

Understanding Foam Inserts for Airbags: A Comprehensive Overview

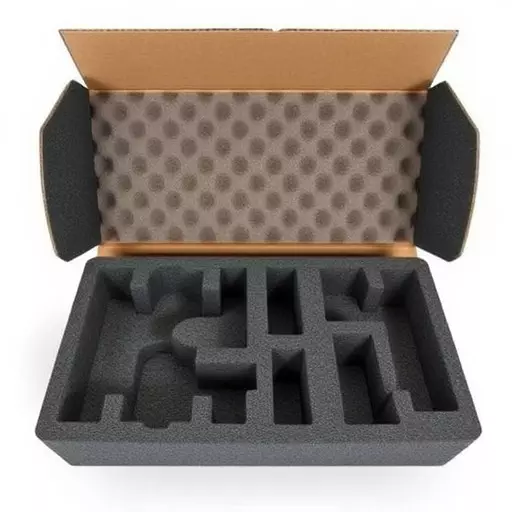

Foam inserts for airbags are integral components in the automotive industry, especially during shipping and transportation. These custom automotive foam inserts play a crucial role in protecting fragile automotive parts, ensuring they arrive at their destination intact and without damage. By carefully designing and implementing these inserts, manufacturers can navigate the challenges of shipping delicate items, maintaining their quality and functionality.

Automotive foam inserts are versatile materials that come in various shapes, sizes, and densities to accommodate different types of components. For instance, a shipping company in Holland, Ohio, specializing in automotive parts transport might use custom foam inserts to securely pack and ship airbags, ensuring they don’t move around during transit. This comprehensive overview highlights the importance of these foam inserts, their diverse applications, and the benefits they bring to the overall logistics process, especially when it comes to safeguarding valuable automotive parts.

The Role of Custom Automotive Foam Inserts in Safety and Protection

Custom automotive foam inserts play a vital role in ensuring safety and protection within the automotive industry, especially when it comes to shipping delicate components. These specialized inserts are designed to fit precisely into specific areas of vehicles, offering a tailored solution for various parts. By using advanced foaming techniques, manufacturers can create lightweight yet robust cushions that secure fragile items during transportation.

For instance, in Holland, Ohio, where the automotive industry thrives, custom foam inserts are widely utilized for shipping sensitive automotive parts. These inserts provide an additional layer of protection, preventing damage caused by shocks, vibrations, and impacts during the supply chain process. With their versatility, they can accommodate unique shapes and sizes, making them indispensable for safeguarding valuable and intricate automotive components.

Why Choose Foam Inserts for Fragile Automotive Parts?

When it comes to protecting fragile automotive parts during shipping and handling, choosing the right material is paramount. This is where foam inserts step in as an ideal solution. Automotive foam inserts, particularly those tailored for specific components, offer a range of benefits that make them a superior choice for many companies in Holland, Ohio, and beyond.

Compared to traditional packing materials, custom automotive foam inserts provide enhanced protection against shocks, vibrations, and impacts. Their rigid yet flexible nature ensures that fragile parts are securely cushioned, reducing the risk of damage during transit. Moreover, these inserts can be designed with precision to perfectly fit various automotive components, offering a snug and secure environment that prevents movement within the packaging. This level of customization is especially valuable for shipping delicate items, ensuring they arrive at their destination in pristine condition.

How to Source and Install Automotive Foam Inserts in Holland, Ohio

In Holland, Ohio, sourcing and installing custom automotive foam inserts is a straightforward process when done right. The first step involves identifying reputable suppliers who specialize in creating tailored foam solutions for various industries, including automotive. These specialists can offer advanced materials designed to protect fragile car parts during shipping and handling. Online platforms and local business directories are excellent resources for finding such suppliers, allowing you to compare prices, quality, and lead times.

When ordering custom automotive foam inserts, provide detailed specifications regarding the dimensions and shape required to accommodate your specific automotive components. Many manufacturers offer quick turnaround times, ensuring that you receive your orders promptly, which is crucial for maintaining efficient logistics operations in Holland, Ohio, or anywhere else. During installation, proper alignment and secure fixation of the foam inserts are essential to guarantee their effectiveness in safeguarding valuable automotive parts from damage during transit.

Unlocking the Benefits: Enhancing Shipment Security with Foam Inserts

Unlocking the Benefits: Enhancing Shipment Security with Foam Inserts

In today’s fast-paced world, ensuring the safe and secure transport of automotive parts is more crucial than ever. This is especially true for fragile components that require meticulous care during shipment. Custom automotive foam inserts have emerged as a game-changer in this domain, offering unparalleled protection for various parts, from delicate electronics to intricate mechanical pieces. By leveraging advanced materials and precise manufacturing techniques, these inserts are designed to perfectly cradle and secure items within shipping containers, significantly reducing the risk of damage during transit.

Located in Holland, Ohio, automotive foam inserts provide a robust solution for businesses seeking to safeguard their valuable inventory. These custom-made products are not one-size-fits-all; instead, they are meticulously engineered based on specific part dimensions and handling requirements. The use of high-quality foams ensures optimal shock absorption and impact resistance, acting as a silent guardian that protects parts from the harsh realities of transportation, whether it’s a long-distance haul or a local delivery.