Automotive foam inserts are crucial for protecting delicate components during shipping, with closed-cell and open-cell foams offering varying protection levels. Custom foam inserts, tailored to specific vehicle parts, are essential in Holland, Ohio's bustling automotive industry. These solutions minimize damage, streamline packaging, and enhance product reliability. A leading manufacturer in Holland adopted custom foam inserts, achieving significant reductions in damaged goods. Selecting a reliable manufacturer involves considering quality, cost, and specialized foam materials like closed-cell polyurethane. Future trends include smarter, sustainable foams and advanced customization techniques for versatile, efficient, and durable foam inserts.

“Unveiling the Revolution of Automotive Foam Inserts: A Comprehensive Guide

Automotive foam inserts are transforming the way we protect and enhance our vehicles. From shipping delicate parts to customizing interiors, these insulators offer a versatile solution. In this article, we explore the diverse world of automotive foam inserts. We’ll delve into materials, customization options, benefits for fragile parts, and their impact on shipping. Additionally, we study real-world applications in Holland, Ohio, and provide insights on selecting the perfect manufacturer. Uncover the future trends shaping this innovative technology.”

- Understanding Automotive Foam Inserts: Materials and Types

- The Role of Customization in Automotive Foam Inserts

- Benefits of Using Foam Inserts for Fragile Parts

- How Foam Inserts Improve Shipping and Protection

- Case Study: Automotive Foam Inserts in Action (Holland, Ohio)

- Choosing the Right Foam Insert Manufacturer

- Future Trends in Automotive Foam Insert Technology

Understanding Automotive Foam Inserts: Materials and Types

Automotive foam inserts are specialized materials designed to protect and cushion delicate components within vehicles. These inserts are crucial for maintaining the integrity and performance of various automotive parts, especially during shipping and handling. The market offers a diverse range of options, allowing manufacturers and technicians to choose the most suitable material for specific applications.

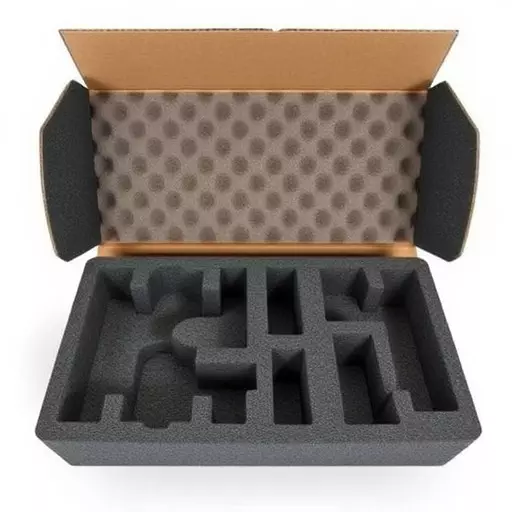

Common types include closed-cell foam, known for its lightweight yet robust properties, making it ideal for protecting fragile items like electronic modules and sensors. Open-cell foam, on the other hand, provides excellent shock absorption but is typically used for less critical components. Custom automotive foam inserts are also available, allowing precise tailoring to fit unique vehicle parts, ensuring optimal protection during transit for businesses based in shipping Holland, Ohio, or elsewhere.

The Role of Customization in Automotive Foam Inserts

In the world of automotive interior components, customization plays a pivotal role in enhancing both functionality and aesthetics. Customized foam inserts are no longer just about comfort; they are essential for protecting fragile automotive parts during shipping and handling. For instance, in Holland, Ohio, where the automotive industry is thriving, businesses often rely on custom automotive foam inserts to ensure the safe arrival of their products. These specialized inserts are tailored to fit specific part dimensions, providing a snug and secure environment that minimizes movement and potential damage during transit.

When it comes to shipping delicate parts, such as those found in high-end vehicles or specialized automotive applications, customization takes on added importance. The ability to design foam inserts precisely for each unique part ensures optimal protection, reducing the risk of cracks, chips, or other forms of damage that can occur due to irregular fitting or insufficient cushioning. By offering custom solutions, manufacturers and suppliers cater to a wide range of clients, from small local businesses to major automotive corporations, addressing diverse needs in the competitive market for automotive foam inserts.

Benefits of Using Foam Inserts for Fragile Parts

Using foam inserts offers numerous advantages when it comes to protecting fragile automotive parts during shipping and handling. These custom-made inserts are specifically designed to fit various car dashboard configurations, ensuring that delicate components like air bags, sensors, and interior panels are securely cushioned. The primary benefit lies in their ability to absorb shock and impact, significantly reducing the risk of damage during transit. This is especially crucial for automotive manufacturers and shipping companies based in areas like Holland, Ohio, where ensuring the integrity of these parts is vital.

Custom automotive foam inserts provide a tailored solution, allowing for precise protection of specific fragile parts. They are crafted from high-quality materials that are both durable and flexible, accommodating different part shapes while offering superior insulation. By utilizing these inserts, manufacturers can streamline their packaging processes, as they simplify the overall packaging design and reduce the likelihood of damage, leading to cost savings and enhanced product reliability.

How Foam Inserts Improve Shipping and Protection

Foam inserts play a pivotal role in enhancing shipping and protection within the automotive industry, particularly for delicate components. These custom-made solutions are designed to provide an extra layer of security during transit, ensuring that fragile automotive parts arrive at their destination unscathed. By creating a padded interior around these items, foam inserts minimize the risk of damage caused by shifting or impact during transportation.

For businesses specializing in shipping automotive parts from Holland, Ohio, or beyond, incorporating foam inserts into their packaging strategy is a game-changer. Customized to fit specific part dimensions, these inserts offer a tailored protection system. This approach not only prevents potential damage but also reduces the likelihood of returns due to defective or broken goods, ultimately streamlining the logistics process and fostering customer satisfaction.

Case Study: Automotive Foam Inserts in Action (Holland, Ohio)

In Holland, Ohio, a leading automotive manufacturer discovered the power of custom automotive foam inserts in protecting their delicate components during shipping. This case study highlights how innovative packaging solutions can significantly reduce damage and improve efficiency. By employing foam inserts tailored to fit specific parts, the company successfully minimized breakage and enhanced the overall quality control process.

The implementation of these advanced foam inserts for shipping in Holland resulted in a notable decrease in damaged goods. The custom-designed foam not only secured the automotive parts but also absorbed shocks and vibrations during transit, ensuring the fragile items arrived safely. This success story underscores the importance of adopting cutting-edge packaging technologies to meet the stringent requirements of modern automotive manufacturing and distribution.

Choosing the Right Foam Insert Manufacturer

When selecting a manufacturer for your custom automotive foam inserts, especially for protecting fragile parts during shipping in Holland, Ohio, it’s crucial to strike a balance between quality and cost-effectiveness. Look for a company with an established track record in the industry, known for their expertise in creating precise, durable foam solutions tailored to specific vehicle models and parts. Experience matters when it comes to understanding the intricacies of different automotive components and ensuring they receive adequate protection during transit.

Reputable manufacturers will offer a wide range of materials suitable for various applications. For fragile parts, opt for inserts made from closed-cell polyurethane foams, renowned for their superior shock absorption and water resistance. These attributes are vital to safeguard delicate automotive components from potential damage during the shipping process. Additionally, consider manufacturers that provide customization options, allowing you to define exact dimensions and specifications to fit seamlessly into your vehicle’s dashboard or any other intricate automotive space.

Future Trends in Automotive Foam Insert Technology

The future of automotive foam insert technology looks promising, with innovative solutions tailored to meet evolving needs in the industry. As companies like those based in Holland, Ohio, specializing in custom automotive foam inserts, continue to lead the way, we can expect to see advanced materials and designs that enhance both performance and protection. One trend is the development of smarter foams that can adapt to different conditions, offering superior shock absorption and insulation for fragile automotive parts during shipping and handling.

Additionally, there’s a growing emphasis on sustainability in the automotive sector, driving research into eco-friendly foam materials that reduce environmental impact without compromising quality. Customization will also play a significant role, with advanced machining techniques enabling precise engineering of foam inserts to fit unique vehicle interior designs and accommodate specialized parts. This trend ensures that automotive foam inserts become even more versatile and efficient, catering to the diverse requirements of modern vehicles and shipping practices.