Automotive foam inserts, custom-made to fit specific car parts, are vital for protecting delicate components like headlights during shipping and storage in regions like Holland, Ohio. These specialized solutions prevent damage from shocks, vibrations, and movements, ensuring the longevity and functionality of fragile automotive parts through advanced foaming technologies. By selecting reputable manufacturers specializing in custom automotive foam inserts, auto industry professionals can enhance safety, efficiency, and cost-effectiveness in shipping processes.

Protective foam inserts are essential components in ensuring the safe transportation of headlights and other delicate automotive parts. In this article, we explore the significance of these specialized solutions, particularly in the context of automotive shipping. From understanding why custom automotive foam inserts matter to choosing the right fit for your specific needs, we delve into the diverse applications that safeguard fragile automotive components during transit. Discover how these innovative products contribute to minimizing damage and enhancing overall part integrity, especially relevant for businesses specializing in auto shipping in Holland, Ohio.

- Understanding the Importance of Protective Foam Inserts for Headlights

- Custom Automotive Foam Inserts: A Tailored Solution

- The Role of Foam Inserts in Safe Automotive Shipping

- How to Choose the Right Foam Insert for Your Headlights

- Real-World Applications: Protecting Fragile Automotive Parts with Foam Inserts

Understanding the Importance of Protective Foam Inserts for Headlights

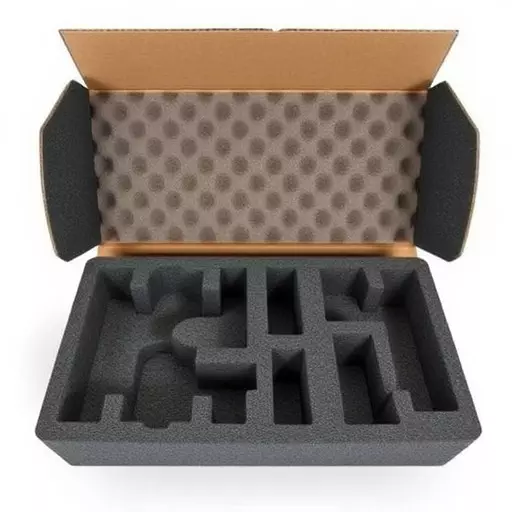

Protective foam inserts play a pivotal role in ensuring the safe transportation and preservation of headlights and other delicate automotive components. These custom automotive foam inserts are designed to fit precisely around the contours of various car parts, offering unwavering protection during shipping and handling. This is particularly crucial for regions like Holland, Ohio, where automotive industries thrive and fragile parts need to be transported over long distances.

When it comes to shipping or storing headlights—which are both intricate and valuable—using the right foam inserts can prevent damage from shocks, vibrations, or sudden movements. Custom-made foam solutions create a secure environment, cushioning against impacts that could otherwise lead to cracks, chips, or complete headlight failure. This is not just about cost savings for auto manufacturers and repair shops; it also guarantees customer satisfaction by ensuring the longevity and functionality of their vehicles’ headlights.

Custom Automotive Foam Inserts: A Tailored Solution

Custom automotive foam inserts have emerged as a tailored solution for protecting delicate and fragile automotive parts during shipping and handling. These specialized inserts are designed to fit precisely within the voids and contours of various vehicle components, offering unparalleled customization and protection. For instance, in Holland, Ohio, where many automotive manufacturers and suppliers are based, custom foam inserts play a crucial role in ensuring that headlights remain unscathed during transit.

By utilizing advanced foaming technologies, these custom automotive foam inserts can be crafted to accommodate the unique dimensions and shapes of specific headlight assemblies. This level of customization ensures that every nook and cranny is padded, preventing damage from impacts or vibrations often encountered during shipping and installation. As a result, automakers and technicians in Holland, Ohio, benefit from enhanced product integrity and reduced warranty claims associated with damaged headlights and other fragile automotive parts.

The Role of Foam Inserts in Safe Automotive Shipping

In the world of automotive shipping, ensuring the safe arrival of components is paramount, especially for delicate items like headlights. This is where custom automotive foam inserts step in as game-changers. These specialized insulators are meticulously designed to fit around fragile automotive parts, providing a protective cushion during transit. By employing foam inserts for fragile automotive parts, such as those in Holland, Ohio, shipping companies can significantly reduce the risk of damage, ensuring that headlights and other components arrive at their destination intact.

The role of automotive foam inserts goes beyond simple protection; they offer a customized solution tailored to the unique dimensions and contours of various car parts. This level of customization is particularly beneficial for odd-shaped or rare components, ensuring they receive the specialized care they need. With custom automotive foam inserts, shipping processes become more efficient and secure, allowing companies to meet the high standards required in the auto industry while maintaining cost-effectiveness.

How to Choose the Right Foam Insert for Your Headlights

When selecting a protective foam insert for your headlights, understanding your specific needs is paramount. Custom automotive foam inserts offer unparalleled precision and customization options to ensure your fragile automotive parts are safeguarded during shipping or storage. Consider factors like the size and shape of your headlights, as well as the level of protection required – whether it’s simply padding for regular transportation or robust cushioning for high-risk scenarios.

Researching reputable manufacturers specializing in automotive foam inserts, such as those found in Holland, Ohio, is wise. These professionals can provide tailored solutions that incorporate advanced materials designed to absorb impact and prevent damage. Look for options that are not only custom-fit but also durable, lightweight, and moisture-resistant to ensure optimal protection for your headlights under various conditions.

Real-World Applications: Protecting Fragile Automotive Parts with Foam Inserts

Protecting Fragile Automotive Parts with Foam Inserts

In today’s fast-paced automotive industry, where components are constantly in transit, from manufacturing plants to dealerships and ultimately to consumers, ensuring the safe arrival of intricate and delicate parts is paramount. This is where custom automotive foam inserts step into the spotlight as a game-changer. These specialized foams, meticulously designed for specific parts like headlights, serve as an essential buffer during shipping, safeguarding against potential damage caused by jostling or impacts.

Real-world applications highlight the effectiveness of these foam inserts in Ohio and beyond. For instance, automotive foam inserts for shipping in Holland, Ohio, have proven invaluable for protecting fragile components during their journey across vast distances. By customizing the foam to fit the unique dimensions of headlights or other parts, manufacturers can ensure that even the most delicate items arrive at their destination intact, enhancing customer satisfaction and reducing returns due to damage.