Automotive foam inserts, customized from polyether or closed-cell foam, offer superior protection for vehicle components during shipping. They are particularly valuable in Holland, Ohio, where efficient logistics require robust cushioning for delicate parts. Customization allows manufacturers to fit specific part sizes and shapes, enhancing both space utilization and overall protection. These inserts are crucial for global automotive manufacturers, minimizing damage risks and customer dissatisfaction by safeguarding fragile items like glass, sensors, and electronics. By balancing protection and cost-efficiency through tailored foam solutions, companies in Holland, Ohio can significantly reduce shipping-related damage claims.

“In today’s automotive industry, hybrid components demand innovative protection solutions. This is where custom automotive foam inserts step in, offering unparalleled advantages for safe component transportation. From safeguarding delicate parts during shipping to enhancing overall vehicle performance, these inserts are a game-changer.

This article explores the world of automotive foam technology, focusing on how customized inserts are revolutionizing hybrid component protection. We’ll delve into materials, benefits, and real-world applications, including a case study of a Holland, Ohio-based auto shipping company.”

- Understanding Automotive Foam Inserts: Materials and Benefits

- Customization in Action: Creating Inserts for Unique Hybrid Components

- The Role of Foam Inserts in Safeguarding Fragile Car Parts During Shipping

- A Case Study: Implementing Foam Inserts at a Holland, Ohio-Based Auto Shipping Company

- Choosing the Right Foam Density: Ensuring Optimal Protection and Cost Efficiency

Understanding Automotive Foam Inserts: Materials and Benefits

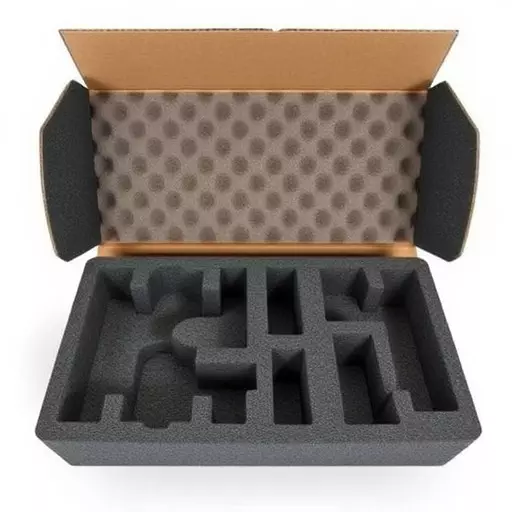

Automotive foam inserts are specialized components designed to protect and secure various parts within a vehicle’s interior or during shipping. These inserts are crafted from a range of materials, each offering unique advantages. Commonly used foams include polyether foam, polypropylene foam, and closed-cell foam, each with distinct properties to cater to different needs. Polyether foam, for instance, is known for its excellent flexibility and shock absorption, making it ideal for wrapping delicate automotive parts like electronics or glass components.

The benefits of incorporating custom automotive foam inserts are multifaceted. They provide exceptional cushioning, ensuring fragile parts arrive intact during shipping, especially in regions like Holland, Ohio, where efficient logistics are key. Additionally, these inserts can create tailored compartments, optimizing space utilization within the vehicle, which is crucial for modern automotive design. Customization allows manufacturers to address specific part sizes and shapes, enhancing overall protection and efficiency, thereby meeting the diverse requirements of the automotive industry.

Customization in Action: Creating Inserts for Unique Hybrid Components

In the realm of hybrid component design, customization is key to ensuring optimal performance and protection. Automotive foam inserts play a vital role in this process, especially when it comes to shipping delicate automotive parts from Holland, Ohio. These specialized insulators are crafted to fit unique dimensions precisely, safeguarding fragile items during transit. Custom automotive foam inserts offer unparalleled versatility, catering to the specific needs of diverse hybrid components.

By utilizing cutting-edge technology and precise manufacturing processes, companies can create foam inserts tailored for intricate shapes and complex geometries. This level of customization ensures that every nook and cranny of a hybrid component is protected, minimizing the risk of damage during shipping. Whether for engine parts, sophisticated electronics, or delicate glass components, custom foam inserts provide a secure environment, ensuring the safe delivery of automotive parts across various distances.

The Role of Foam Inserts in Safeguarding Fragile Car Parts During Shipping

In today’s fast-paced automotive industry, ensuring the safe transportation of delicate components is paramount to maintaining quality and reducing damage during shipping. This is where custom automotive foam inserts play a pivotal role. These specialized insulators are meticulously designed to safeguard fragile parts, such as glass, sensors, and intricate electronics, from potential hazards like impacts, vibrations, and sudden temperature changes. By employing advanced materials and precise cutting techniques, these custom foam inserts create a protective cushion around the components, mitigating risks associated with standard shipping methods.

For automotive manufacturers and suppliers in Holland, Ohio, or across the globe, opting for tailored foam inserts offers significant advantages. Customization allows for perfect fitment within specific part packaging, maximizing protection and minimizing the risk of damage. Moreover, using innovative materials like closed-cell foam enhances shock absorption, ensuring that fragile car parts arrive at their destination intact and undamaged. This not only reduces costs associated with returned or replaced components but also maintains customer satisfaction by delivering superior-quality automotive parts every time.

A Case Study: Implementing Foam Inserts at a Holland, Ohio-Based Auto Shipping Company

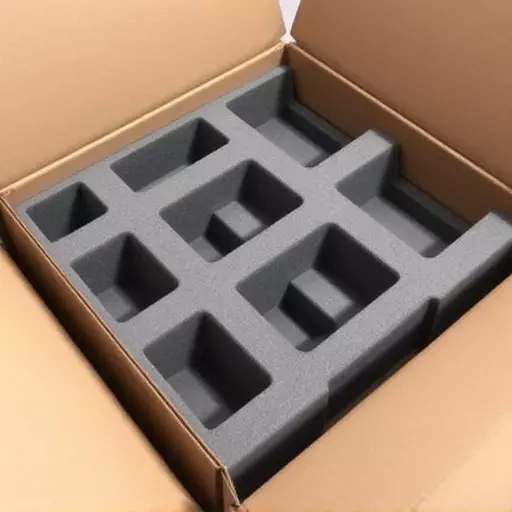

A Holland, Ohio-based auto shipping company faced a challenge when it came to securing and protecting their valuable, fragile automotive parts during transit. The traditional packaging methods were failing to prevent damage, resulting in frequent claims from clients. In light of this issue, they decided to implement custom automotive foam inserts as a game-changer solution.

By collaborating with experts in the field, the company designed and integrated specialized foam inserts tailored to their specific shipping requirements. These custom foam solutions provided a protective cushion around each fragile part, ensuring that even during the hustle and bustle of transportation, the items remained intact. The use of automotive foam inserts for shipping in Holland, Ohio, not only reduced damage but also enhanced the overall efficiency of their operations.

Choosing the Right Foam Density: Ensuring Optimal Protection and Cost Efficiency

When selecting the appropriate foam density for automotive foam inserts, balancing protection and cost-efficiency is crucial. For fragile automotive components, a higher density foam offers superior shock absorption and cushioning, ensuring parts arrive safely during shipping from Holland, Ohio or anywhere else. However, this comes at a price; denser foams are generally more expensive.

To strike the right balance, consider the fragility of your specific automotive parts. Delicate items like glass, ceramic, or intricate plastic components may require a higher density foam to withstand potential impacts and vibrations during transit. In contrast, less fragile parts could use lower density foams, which are more cost-effective while still providing adequate protection. Custom automotive foam inserts allow for precise tailoring to your needs, ensuring both optimal protection and budget management.