Automotive foam inserts, tailored to specific engine components in Holland, Ohio, are a cutting-edge solution for safe shipping. These custom insulators provide structural support and superior cushioning, reducing damage risk during transit. Crafted from high-quality materials, they safeguard fragile items, saving time and costs for manufacturers and shipping companies. With advanced technologies and precise molding techniques, specialists create foam inserts that perfectly conform to unique component shapes and sizes, emphasizing precision in the automotive industry. Custom automotive foam inserts are a game-changer, offering unparalleled protection and cost savings for diverse, delicate parts.

“Revolutionize your automotive engineering with innovative foam inserts—a game-changer for protecting and optimizing engine components. This comprehensive guide explores the world of custom automotive foam inserts, their material science, and diverse applications. From enhancing safety during shipping to tailored solutions for specific needs, we delve into the benefits and future trends. Discover how Dutch Ohio automotive companies harness foam technology to create lightweight, durable protections for fragile parts, ensuring efficiency and peace of mind.”

- Understanding Foam Inserts: Material and Benefits for Automotive Parts

- Customization in Action: Creating Foam Inserts for Specific Automotive Needs

- The Role of Foam Inserts in Safe Shipping of Fragile Automotive Components

- Case Study: How Automotive Companies in Holland, Ohio Use Foam Inserts

- Selecting the Right Foam: Properties and Applications in Automotive Insulation

- Future Trends: Innovations in Foam Insert Technology for the Automotive Industry

Understanding Foam Inserts: Material and Benefits for Automotive Parts

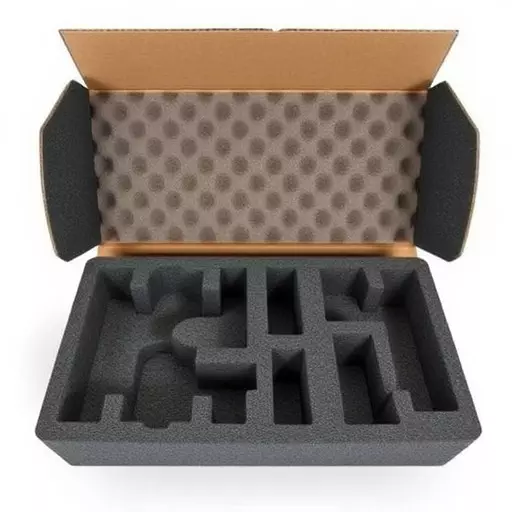

Foam inserts are an innovative solution for protecting and supporting sensitive automotive components during shipping and storage. These custom-made insulators are designed to fit precisely around various engine parts, offering both structural support and cushioning. Crafted from high-quality materials, they ensure the safe transit of fragile items, which is especially crucial in the automotive industry where precision and reliability are paramount.

Automotive foam inserts provide numerous benefits. They offer superior shock absorption, minimizing the risk of damage to delicate parts during transportation. The material’s flexibility allows it to conform to the shape of irregular components, offering customized protection. Moreover, these inserts can be tailored to specific dimensions, making them ideal for unique automotive parts. This level of customization ensures that valuable engine components arrive at their destination intact, saving manufacturers and shipping companies time and money.

Customization in Action: Creating Foam Inserts for Specific Automotive Needs

In the world of automotive maintenance and shipping, customization is key to ensuring optimal protection for various components. This is where custom automotive foam inserts come into play. These meticulously designed insulators are not one-size-fits-all; instead, they are tailored to fit specific automotive needs, be it a unique engine part shape or a fragile component requiring extra care during transit.

For instance, companies in Holland, Ohio, specializing in automotive foam inserts offer a range of services catering to diverse vehicle requirements. From custom-cut foams for shipping delicate parts to creating specialized molds for irregular engine components, these specialists ensure that every automotive need is addressed. By utilizing advanced cutting technologies and state-of-the-art molding techniques, they produce foam inserts that not only protect but also perfectly accommodate the specific dimensions of various automotive parts.

The Role of Foam Inserts in Safe Shipping of Fragile Automotive Components

In today’s fast-paced automotive industry, ensuring the safe transportation of delicate components is paramount to maintaining quality and minimizing damage during shipping. This is where custom automotive foam inserts step in as invaluable tools. These specialized inserts are meticulously designed to fit specific parts, providing a protective cushion that prevents movement and potential harm. By utilizing advanced materials, foam inserts create a secure environment for fragile automotive components, whether they’re heading to dealers or being installed in new vehicles.

When it comes to shipping from Holland, Ohio, or any other location, the role of these custom foam solutions is crucial. They safeguard against vibrations, shocks, and impacts that could occur during transit, ensuring that valuable parts reach their destinations intact. This is especially critical for intricate engine components where precision and safety are paramount. With automotive foam inserts, shipping becomes a more secure process, reflecting the meticulous attention to detail required in the automotive manufacturing sector.

Case Study: How Automotive Companies in Holland, Ohio Use Foam Inserts

Automotive companies in Holland, Ohio have been leveraging custom foam inserts as a game-changer in their operations, particularly for shipping delicate engine components. These innovative solutions are designed to provide unparalleled protection during transit, ensuring the safe arrival of fragile automotive parts. By employing foam inserts tailored to specific part sizes and shapes, these manufacturers can significantly reduce damage and return rates, thereby enhancing overall efficiency.

In this case study, Holland’s automotive giants have discovered that custom foam not only secures parts but also optimizes space utilization in shipping crates. This efficient packaging method is especially beneficial for various engine components, from intricate valve trains to delicate sensors. With the right foam insert strategy, these companies can meet the stringent quality standards required in the modern auto industry while keeping logistics costs manageable.

Selecting the Right Foam: Properties and Applications in Automotive Insulation

When it comes to selecting the right foam for automotive applications, especially for shipping sensitive engine parts from Holland, Ohio, understanding the properties is key. Custom automotive foam inserts offer a tailored solution for protecting fragile components during transit. The ideal material should possess excellent shock absorption and cushioning capabilities to prevent damage caused by vibrations and impacts during transport.

Automotive foam inserts are designed with specific density and rigidity levels to cater to diverse part shapes and sizes. For instance, low-density foams are lightweight yet effective in cushioning delicate parts, while higher-density options provide more robust protection for heavier components. This customization ensures that engine parts, no matter how intricate or fragile, receive the appropriate insulation during shipping, enhancing overall safety and reducing the risk of damage.

Future Trends: Innovations in Foam Insert Technology for the Automotive Industry

The future of automotive foam inserts is looking bright with continuous innovation and advancements in technology. One prominent trend is the development of custom, tailored foam inserts designed specifically for unique and fragile automotive parts. This personalized approach ensures optimal protection during shipping and handling, which is especially crucial for high-value components. Manufacturers are leveraging advanced materials and manufacturing techniques to create lightweight yet robust foams capable of withstanding extreme conditions while providing superior shock absorption.

Additionally, there’s a growing emphasis on sustainable foam insert solutions. Environmental considerations drive the exploration of eco-friendly materials that minimize waste and reduce the carbon footprint associated with traditional automotive shipping. As the industry shifts towards more sustainable practices, we can expect to see innovative foam inserts made from recycled content or biodegradable materials, aligning with the global push for greener logistics in Holland, Ohio, and beyond.