Fragile items demand specialized attention, and CNC machining offers tailored solutions. Located in Holland, Ohio, advanced manufacturers use this technology to create precise, custom components for enhanced protection during transport and storage. Steel racks with specific features provide robust storage, integrating CNC-machined packaging components for optimal space utilization. This method improves product integrity, reduces waste, and streamlines processes, benefiting industries handling delicate products. Local adoption has positive impacts, revolutionizing traditional methods and ensuring safer goods transit. Advanced technologies in Holland, Ohio, are transforming fragile item handling with precision engineering support.

In today’s world, safely transporting fragile items is paramount across various industries. From delicate electronics to artistic creations, understanding the unique challenges of packaging these goods is essential. This article explores innovative solutions, focusing on the transformative role of CNC machining in creating custom packaging components tailored to specific needs. We delve into the advantages of steel racks for fragile items, highlighting their effectiveness through real-world examples from the Holland, Ohio industry. Additionally, we discuss future trends, including advanced technologies that promise to revolutionize fragile item handling.

- Understanding the Challenges of Packaging Fragile Items

- The Role of CNC Machining in Customizing Packaging Solutions

- Advantages of Steel Racks for Delicate Goods

- Designing and Manufacturing CNC-Machined Packaging Components

- Case Studies: Successful Implementation in the Holland, Ohio Industry

- Future Trends: Enhancing Fragile Item Handling with Advanced Technologies

Understanding the Challenges of Packaging Fragile Items

Fragile items present unique challenges when it comes to packaging and storage. These objects often require specialized handling due to their delicate nature, which means finding safe and secure containment solutions is paramount. In the world of precision engineering, Computer Numerical Control (CNC) machining has emerged as a game-changer for the packaging industry, especially in Holland, Ohio. By leveraging CNC machining technologies, manufacturers can create custom cnc-machined packaging components tailored to specific fragile item needs.

This innovative approach offers numerous benefits, such as enhanced protection through precise dimensions and material selection, reduced waste, and cost-efficiency. Customized CNC-machined parts ensure that every fragile item is safely enveloped, minimizing the risk of damage during transportation and storage. This is particularly valuable for industries where product integrity is paramount, demonstrating the significant advantages of integrating CNC machining into packaging processes.

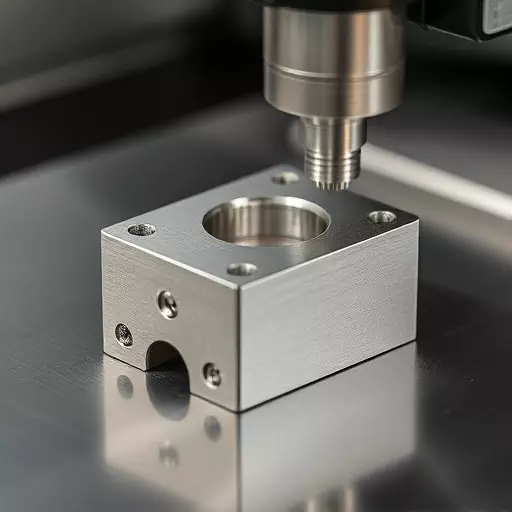

The Role of CNC Machining in Customizing Packaging Solutions

In today’s competitive marketplace, where products are often delicate and require specialized handling, custom packaging solutions are essential. This is where CNC (Computer Numerical Control) machining plays a pivotal role in the packaging industry, offering unparalleled precision and versatility. Located in Holland, Ohio, many cutting-edge manufacturers utilize CNC machining for packaging, providing innovative and tailored solutions to protect fragile items during transportation and storage. By employing advanced machinery and computer-aided design software, these specialists can create custom CNC-machined packaging components that perfectly accommodate specific product dimensions and needs.

The benefits of CNC machining in the packaging industry are manifold. It enables the production of intricate and precise components, ensuring secure fitment around delicate items. This customization goes beyond standard rack designs, allowing for unique storage solutions tailored to prevent damage and breakage. Moreover, CNC machining offers speed, efficiency, and cost-effectiveness, making it a game-changer in creating specialized steel racks for fragile products. These racks can be designed with specific considerations like moisture resistance or enhanced structural integrity, ensuring the safe transit of goods.

Advantages of Steel Racks for Delicate Goods

Steel racks offer numerous advantages when it comes to storing fragile items, making them an ideal choice for many businesses in the packaging industry. One of the key benefits is their durability and strength. These racks are designed with robust steel construction, capable of withstanding heavy loads and extreme conditions, ensuring your delicate goods remain safe and secure. This is especially important for products that require specialized handling, such as those produced through CNC machining in Holland, Ohio, where precision and stability are paramount.

Additionally, custom CNC-machined packaging components can be seamlessly integrated into these steel racks. The flexibility of CNC machining allows for the creation of unique, tailored solutions to accommodate various product shapes and sizes, optimizing space utilization. This is a significant advantage for businesses seeking efficient storage systems, especially in a dynamic packaging environment where benefits of CNC machining in packaging processes play a pivotal role in enhancing overall productivity and ensuring product integrity.

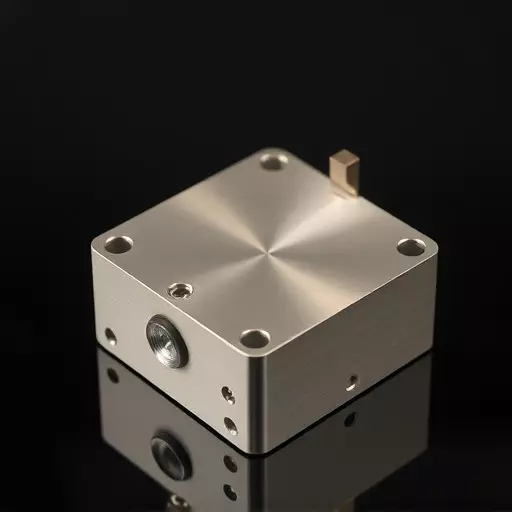

Designing and Manufacturing CNC-Machined Packaging Components

In the world of modern packaging, precision and customization are key to ensuring product safety and enhancing brand image. This is where CNC (Computer Numerical Control) machining plays a pivotal role, especially in Holland, Ohio, where advanced manufacturing techniques have made significant strides. Custom CNC-machined packaging components offer unparalleled accuracy and detail, catering specifically to the unique requirements of fragile items like glassware, ceramics, or delicate electronics. By employing CNC machinery, manufacturers can produce intricate designs with tight tolerances, ensuring a perfect fit for various products.

The benefits of CNC machining in the packaging industry are multifaceted. It allows for complex geometry and custom shapes that traditional manufacturing methods may struggle to achieve. Moreover, CNC-machined parts offer improved consistency and quality, reducing waste and enhancing overall efficiency. Customization enables designers to incorporate specific features like precise dimensions, intricate patterns, or integrated protection mechanisms directly into the packaging, making it suitable for diverse product needs. This level of tailoring ensures that fragile items receive specialized care during transportation and storage, thereby minimizing damage and loss.

Case Studies: Successful Implementation in the Holland, Ohio Industry

In Holland, Ohio, the manufacturing landscape has seen a significant transformation with the adoption of advanced technologies, particularly in the packaging industry. One such innovation is the utilization of steel racks for fragile items, enhanced through custom CNC-machined packaging components. This approach has not only streamlined production processes but also significantly improved product protection during storage and transportation.

Case studies from local manufacturers highlight the benefits of CNC machining in packaging. For instance, a leading CNC machining company in Holland has successfully implemented custom-designed steel racks for various fragile items, including glass bottles and delicate electronics components. The precision engineering ensures these racks provide robust support while minimizing the risk of damage. This implementation has led to reduced shipping costs, faster turnaround times, and enhanced customer satisfaction due to the improved quality and integrity of packaged goods.

Future Trends: Enhancing Fragile Item Handling with Advanced Technologies

The future of fragile item handling is poised for a significant upgrade with advanced technologies emerging from industries like CNC machining for packaging in Holland, Ohio. Custom CNC-machined packaging components are becoming increasingly popular due to their precision and ability to cater to complex product requirements. This technology revolutionizes traditional manufacturing methods, enabling the production of intricate designs and precise dimensions that were once challenging to achieve. By leveraging CNC machining, manufacturers can create specialized racks and containers tailored to the unique needs of fragile items, ensuring enhanced protection during transportation and storage.

The benefits of CNC machining in the packaging industry are vast. It offers unparalleled accuracy, allowing for meticulous creation of components that perfectly accommodate various fragile items. This precision reduces the risk of damage, which is crucial for maintaining product integrity. Moreover, CNC machining facilitates rapid prototyping and customization, enabling businesses to adapt quickly to changing market demands and customer preferences. As technology advances, we can expect even more innovative solutions, further streamlining fragile item handling processes and ensuring that products reach their destinations safely and intact.