Custom injection molded packaging from Holland, Ohio-based manufacturers is revolutionizing heavy machinery transportation. This innovative solution offers superior structural integrity, precise design for space optimization, and tailored features like ventilation and access points, ensuring unique machinery components arrive undamaged. By leveraging professional injection molding services, these manufacturers provide enhanced durability, corrosion resistance, reinforced corners, secure fastening mechanisms, and internal dividers, streamlining logistics, reducing damage during transit, and enhancing operational efficiency in diverse environments. The benefits of injection molded packaging include improved safety, visibility, and brand visibility through custom designs and logo integrations.

In today’s globalized world of heavy machinery, efficient storage and transportation are paramount. Steel containers have emerged as a game-changer in this domain, offering robust solutions for securing specialized equipment. This article delves into the significance of steel containers, highlighting their role in streamlining logistics. We explore custom injection molded packaging provided by Holland, Ohio-based manufacturers, discussing its advantages for heavy machinery storage and transport. Additionally, we scrutinize the benefits of professional injection molding services, focusing on design considerations and the overall impact on supply chain efficiency.

- Understanding Steel Containers: Their Role in Heavy Machinery Storage and Transport

- Custom Injection Molded Packaging: A Holland, Ohio-based Solution for Specialized Equipment

- Advantages of Injection Molding for Heavy Machinery Packaging

- Designing Steel Containers: Key Considerations for Safety and Efficiency

- The Impact of Professional Injection Molding Services on Supply Chain Logistics

Understanding Steel Containers: Their Role in Heavy Machinery Storage and Transport

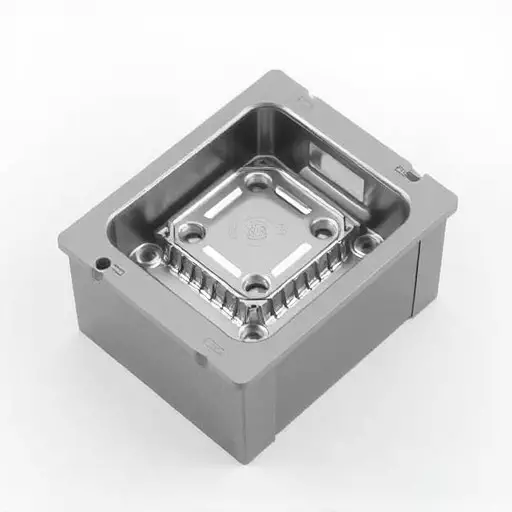

Steel containers have become indispensable for storing and transporting heavy machinery due to their robust construction and versatility. These containers, often formed through professional injection molding services in Holland, Ohio, offer a range of benefits tailored to demanding industrial needs. Custom injection molded packaging is designed to withstand extreme conditions, from harsh weather to rough handling during transit, ensuring that sensitive equipment arrives undamaged.

The advantages of injection molded packaging extend beyond structural integrity. Its precise design allows for optimal utilization of space, streamlining storage and simplifying transportation logistics. Moreover, these containers can be tailored with specific features like ventilation, access points, or specialized compartments to accommodate unique machinery components, enhancing safety and efficiency in both storage and movement of heavy machinery.

Custom Injection Molded Packaging: A Holland, Ohio-based Solution for Specialized Equipment

Holland, Ohio-based companies are at the forefront of revolutionizing heavy machinery transportation with their cutting-edge solution: custom injection molded packaging. This innovative approach offers unparalleled protection for specialized equipment, ensuring safe and secure delivery across various terrains. By leveraging professional injection molding services, manufacturers create bespoke containers tailored to the unique dimensions and requirements of each piece of machinery.

The benefits of this method are manifold. Injection molded packaging provides superior shock absorption, crucial for vulnerable components during transit. Its seamless design also eliminates potential crevices where debris can accumulate, a common issue with traditional packaging. Moreover, these customized containers offer enhanced visibility, allowing handlers to inspect equipment more efficiently. With a focus on both protection and efficiency, Holland’s injection molding experts are transforming the way heavy machinery is transported, setting a new standard in the industry.

Advantages of Injection Molding for Heavy Machinery Packaging

Injection Molding offers numerous advantages for heavy machinery packaging, especially when paired with custom injection molded packaging Holland Ohio provides. This manufacturing process allows for precise creation of complex shapes and structures tailored to specific machine components. By using Injection Molding, manufacturers can produce durable, lightweight, and cost-effective packaging solutions that ensure the safe transportation and secure placement of hefty equipment.

Professional injection molding services enhance product protection by incorporating specialized features like shock absorption, impact resistance, and precise fitment. The benefits of injection molded packaging extend to enhanced brand visibility as well. Custom designs and logo integrations on these packages not only elevate the overall aesthetics but also serve as a powerful marketing tool, reinforcing the company’s identity among its heavy machinery clientele.

Designing Steel Containers: Key Considerations for Safety and Efficiency

When designing steel containers for heavy machinery and industrial applications, safety and efficiency are paramount. Custom injection molded packaging from Holland, Ohio-based providers offers a range of benefits. These specialized packaging solutions are engineered to withstand extreme conditions, protect valuable equipment, and ensure easy handling and transportation.

Professional injection molding services allow for precise customization, incorporating features like reinforced corners, secure fastening mechanisms, and internal dividers to accommodate diverse machinery sizes and shapes. The use of high-quality steel ensures durability and corrosion resistance, vital factors in environments where moisture or harsh weather conditions are prevalent. By leveraging the benefits of injection molded packaging, businesses can streamline logistics, reduce damage during transit, and ultimately enhance operational efficiency.

The Impact of Professional Injection Molding Services on Supply Chain Logistics

In today’s competitive market, efficient supply chain logistics are paramount for businesses, especially those dealing in heavy machinery. One innovative solution gaining traction is the utilization of steel containers, meticulously crafted through professional injection molding services. These services, available in Holland, Ohio, offer a multitude of benefits, transforming traditional packaging methods. Custom injection molded packaging provides unparalleled strength and durability, ensuring the safe transportation of intricate machinery components.

By outsourcing to professionals, manufacturers can expect precise, cost-effective solutions tailored to their specific needs. Injection molding enables the creation of complex shapes and structures that traditional packaging may struggle with, enhancing overall efficiency in logistics. This advanced approach not only streamlines distribution but also reduces waste, making it an eco-friendly choice for forward-thinking businesses.