Custom-molded foam inserts made from lightweight expanded polypropylene (EPP) in Holland, Ohio, offer numerous advantages for various industries. They provide superior shock absorption, are environmentally friendly due to their recyclability and biodegradability, and can be tailored to specific product needs. These EPP foam solutions reduce transportation costs, minimize environmental impact, and enhance product protection during transit. Their versatility makes them a popular choice in the shipping, logistics, and packaging sectors for optimizing supply chains and reducing waste.

Discover the transformative power of custom-molded foam inserts, a game-changer in packaging innovation. This comprehensive guide explores the intricate world of Expanded Polypropylene (EPP) foam solutions, highlighting their advantages over traditional materials. From lightweight EPP molded foam packaging in Holland, Ohio, to its environmental sustainability, we delve into real-world applications and design customization options. Uncover how these inserts revolutionize shipping, ensuring fragile items arrive intact. Embrace the future of efficient, eco-friendly packaging.

- Understanding Custom-Molded Foam Inserts: A Comprehensive Overview

- Lightweight EPP Molded Foam Packaging: Unlocking Efficiency in Holland, Ohio

- The Advantages of Epp Foam Packaging Over Traditional Materials

- How Expanded Polypropylene (EPP) Foam Solutions Revolutionize Shipping

- Design and Customization Options for Your Unique Packaging Needs

- Environmental Impact and Sustainability with EPP Foam Inserts

- Case Studies: Real-World Success Stories of EPP Foam Packaging

Understanding Custom-Molded Foam Inserts: A Comprehensive Overview

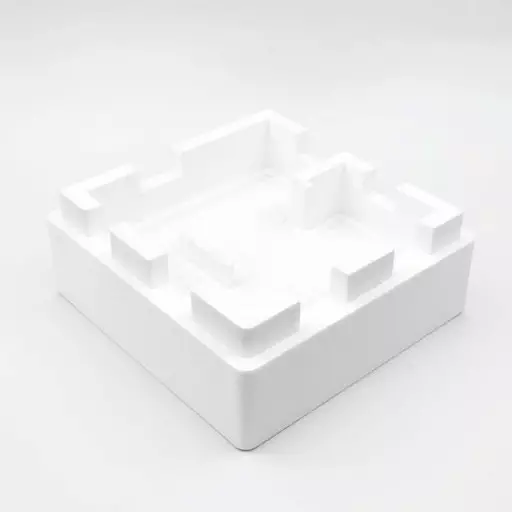

Custom-molded foam inserts are innovative packaging solutions that offer a multitude of benefits for various industries. These lightweight Epp molded foam packaging, often made from expanded polypropylene (EPP), are designed to perfectly fit and protect products of all shapes and sizes. With their unique structure, they provide excellent shock absorption and cushioning, ensuring fragile items arrive at their destination undamaged.

The versatility of custom-molded foam inserts is a significant advantage. They can be tailored to specific product requirements, offering both structural support and product presentation. This level of customization not only enhances product security but also allows brands to create visually appealing packaging that reflects their identity. Additionally, EPP foam solutions are known for their environmental benefits; they are recyclable and biodegradable, making them an eco-friendly alternative to traditional packaging materials.

Lightweight EPP Molded Foam Packaging: Unlocking Efficiency in Holland, Ohio

In Holland, Ohio, businesses are discovering the transformative power of lightweight EPP molded foam packaging. This innovative solution is revolutionizing the way products are protected during transit, offering numerous benefits that traditional packaging methods struggle to match. Expanded polypropylene (EPP) foam, known for its exceptional strength-to-weight ratio, provides superior shock absorption and impact resistance, ensuring delicate items arrive intact and undamaged.

By adopting lightweight EPP molded foam packaging, businesses in Holland, Ohio, can streamline their supply chains, reduce transportation costs, and minimize environmental impact. The versatility of EPP foam allows for custom-molded inserts tailored to the exact dimensions and shape of various products, maximizing space utilization and minimizing waste. This efficiency is particularly valuable for local companies looking to enhance their competitive edge in today’s fast-paced market.

The Advantages of Epp Foam Packaging Over Traditional Materials

Custom-molded foam inserts made from Expanded Polypropylene (EPP) offer a range of advantages over traditional packaging materials, making them a popular choice for many industries. One of the key benefits is their lightweight nature; EPP is significantly lighter than many alternative foams, which makes it more cost-effective to transport and handles with ease. This feature is especially valuable for businesses in Holland, Ohio, aiming to reduce shipping costs and carbon footprints.

Additionally, EPP foam provides superior shock absorption and protection, making it ideal for safeguarding delicate items during transit. Its unique cellular structure creates a lightweight yet robust barrier, ensuring products reach their destination intact. Moreover, this material is highly versatile, allowing for precise molding into custom shapes, providing an excellent fit for various products while minimizing material waste—a significant advantage over traditional packaging solutions.

How Expanded Polypropylene (EPP) Foam Solutions Revolutionize Shipping

In the world of shipping and logistics, the need for innovative and sustainable packaging solutions is paramount. This is where Expanded Polypropylene (EPP) Foam Solutions step in as true game-changers. These lightweight epp molded foam packaging from Holland, Ohio, offer a multitude of benefits that traditional packaging methods simply can’t match. By utilizing advanced molding techniques, EPP transforms into customizable, lightweight, and durable protective materials.

The versatility of EPP foam is particularly evident when it comes to protecting delicate items during transit. Its unique cellular structure provides superior shock absorption, ensuring fragile products arrive safely at their destination without the need for excessive bulk. Moreover, the benefits of EPP foam packaging extend beyond its performance; it’s also environmentally friendly, as EPP is recyclable and biodegradable, contributing to a greener supply chain.

Design and Customization Options for Your Unique Packaging Needs

When it comes to designing and customizing your packaging needs, especially for unique or specialized products, lightweight EPP molded foam offers an array of options. This versatile material is renowned for its exceptional impact resistance and ability to provide precise protection for fragile items. The process begins with understanding your product’s dimensions and requirements; from there, skilled manufacturers can create custom inserts tailored to fit perfectly within your packaging.

One of the key advantages of EPP foam is its adaptability. It can be molded into various shapes and densities, ensuring that your products are securely nestled during transit. Whether you’re in need of a delicate instrument kit or a specialized container for electronic components, expanded polypropylene foam solutions provide both protection and convenience. The benefits extend to cost-effectiveness, as the material’s light weight reduces overall packaging expenses, making it an ideal choice for many businesses in Holland, Ohio, and beyond.

Environmental Impact and Sustainability with EPP Foam Inserts

Custom-molded foam inserts made from Expanded Polypropylene (EPP) offer a sustainable solution for packaging in Holland, Ohio and beyond. EPP foam is known for its lightweight nature, which significantly reduces the environmental impact of transportation compared to denser materials. This is particularly beneficial for shipping delicate items, as it minimizes the risk of damage during transit while cutting down on fuel consumption and carbon emissions.

The production process of EPP foam also aligns with eco-friendly practices. Made from a 100% recyclable thermoplastic polymer, EPP can be recycled multiple times without loss of quality. This extended recyclability, coupled with its superior cushioning properties, makes EPP foam an attractive choice for businesses seeking to adopt greener packaging solutions while reaping the benefits of lightweight epp molded foam packaging.

Case Studies: Real-World Success Stories of EPP Foam Packaging

In the world of packaging, custom-molded foam inserts made from Expanded Polypropylene (EPP) foam are a game-changer. Holland, Ohio-based companies have successfully leveraged these lightweight EPP molded foam packages to offer unparalleled protection for diverse products, from fragile electronics to delicate glassware. Real-world success stories highlight several key benefits of EPP foam packaging: its exceptional shock absorption properties, ability to conform to irregular shapes, and superior cost-effectiveness compared to traditional packaging materials.

These case studies demonstrate how EPP foam solutions can significantly enhance product security during transit, reduce overall shipping costs, and minimize environmental impact due to the material’s recyclability. The versatility of custom-molded foam inserts ensures that businesses across various sectors can benefit from these innovative packaging innovations, solidifying EPP foam as a preferred choice for modern, efficient, and sustainable logistics.