Automotive foam inserts from companies in Holland, Ohio, are crucial for protecting and securing delicate components during shipping. Customized to fit specific vehicle models and parts, these innovative padding materials offer superior shock absorption and impact resistance. Ideal for classic cars or advanced tech displays, the soft yet robust nature of the foam safeguards fragile automotive parts. By customizing inserts tailored to each vehicle model, car owners can achieve a personalized interior while safeguarding their valuable investments. Local manufacturers in Holland, Ohio, cater to these needs, ensuring product integrity throughout production and delivery processes with faster turnaround times and better communication.

“Revolutionize your vehicle’s interior with the power of custom automotive foam inserts. This comprehensive guide explores the multifaceted world of these innovative solutions, from their crucial role in shipping and protection to securing fragile auto components. Discover how foam inserts, made with advanced materials, offer unparalleled benefits for car makers and enthusiasts alike. Learn about customization, installation, and why choosing local experts like Holland, Ohio services can make all the difference in achieving optimal results for your automotive foam inserts needs, especially when prioritizing fragile auto parts safety.”

- Understanding Automotive Foam Inserts: Materials and Benefits

- Customization: Creating Inserts for Unique Vehicle Dashboards

- The Role of Foam Inserts in Shipping and Protection

- How to Choose the Right Foam Density for Different Parts

- Common Applications: Fragile Auto Components Secured

- Installation Process: A Step-by-Step Guide

- Why Select Local Experts: Benefits of Using Holland, Ohio Services

Understanding Automotive Foam Inserts: Materials and Benefits

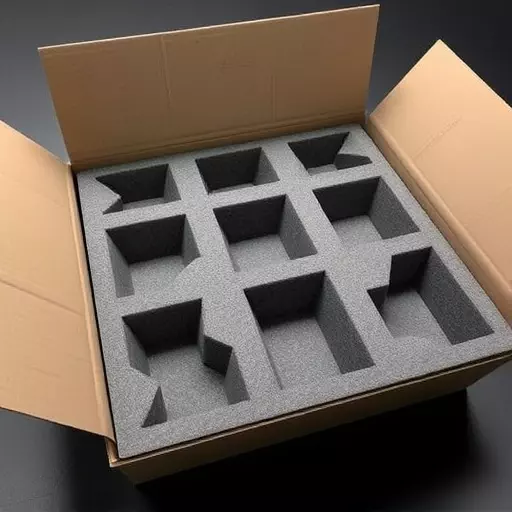

Automotive foam inserts are specialized padding materials designed to protect and secure various components within a vehicle’s interior, particularly during shipping and handling. These inserts are crafted from innovative foams that offer superior shock absorption and impact resistance, making them indispensable for safeguarding delicate automotive parts. The primary advantage lies in their customizability; businesses like Shipping Holland Ohio can create tailored foam solutions to fit the unique dimensions of specific car models and components.

By utilizing custom automotive foam inserts, fragile items such as electronic control units (ECUs), sensors, and other sensitive parts are shielded from potential damage caused by movement during transit. The foam’s flexibility allows it to conform to irregular shapes, providing a snug fit that prevents shifting and reducing the risk of breakage. This is especially crucial for industries that rely on efficient shipping processes, ensuring the safe arrival of automotive parts across long distances.

Customization: Creating Inserts for Unique Vehicle Dashboards

In the world of automotive customization, every detail matters, and that includes the dashboard. Custom automotive foam inserts offer a unique way to enhance both functionality and aesthetics. These precision-cut foams are designed to fit seamlessly into a vehicle’s dashboard, accommodating various shapes and contours. Whether it’s a classic car with intricate gauges or a modern SUV with advanced tech displays, custom foam inserts can transform the interior space.

For those seeking to protect fragile automotive parts during shipping or storage in Holland, Ohio, these inserts are an excellent solution. The soft yet robust nature of foam provides cushioning and impact absorption, ensuring that delicate components remain unscathed. This is particularly useful for rare classic cars or custom builds where every part must be preserved. With the ability to create inserts tailored to specific vehicle models, car owners can achieve a personalized touch while also safeguarding their precious automotive investments.

The Role of Foam Inserts in Shipping and Protection

Foam inserts play a crucial role in the shipping and protection of automotive components, especially when it comes to delicate and fragile items. In the bustling automotive industry, where precision and safety are paramount, custom automotive foam inserts have become indispensable. These specialized products are tailored to fit specific vehicle parts, ensuring a snug and secure hold during transportation. By using high-quality foams, manufacturers can create protective barriers that safeguard against potential damage caused by shocks, vibrations, or sudden impacts during shipping.

For example, in Holland, Ohio, where automotive manufacturing and distribution centers are prevalent, foam inserts are widely utilized to protect valuable components. Customized for various parts, from engine blocks to dashboard panels, these inserts provide a buffer zone that absorbs and distributes force, preventing costly damages. This is particularly important for fragile automotive parts, ensuring they reach their destinations in pristine condition, which is essential for maintaining customer satisfaction and the reputation of automotive businesses.

How to Choose the Right Foam Density for Different Parts

When it comes to selecting the ideal foam density for your automotive dashboard components, understanding the specific needs of each part is key. Density is measured in pounds per cubic foot (lb/ft³) and plays a crucial role in both the performance and protection of fragile automotive parts during shipping. For instance, custom automotive foam inserts designed for delicate items like screens or sensors should have lower densities (around 1.5-2 lb/ft³) to ensure minimal damage and maximum cushioning.

In contrast, sturdier components like armrests or console panels can accommodate slightly higher density foams (2.5-3.5 lb/ft³) as they require more support while still offering shock absorption. Companies specializing in automotive foam inserts for shipping in Holland, Ohio, often cater to these variations by offering a range of custom options. By choosing the right foam density, you can guarantee that your automotive parts arrive safely and securely, tailored to their unique vulnerabilities.

Common Applications: Fragile Auto Components Secured

In the automotive industry, the need for effective protection during transportation is paramount, especially when dealing with delicate components. This is where custom automotive foam inserts step in as a game-changer. These specialized inserts are designed to securely cradle and protect fragile auto parts, ensuring they arrive at their destination in pristine condition. Whether it’s a precision-engineered engine component or a delicate interior panel, the custom foam inserts act as a protective cocoon during shipping.

For instance, in Holland, Ohio, automotive foam insert manufacturers cater to the region’s flourishing automotive sector by offering tailored solutions for various components. From shipping sensitive electrical systems to safeguarding glass parts during installation, these foam inserts play a crucial role in maintaining the integrity of automotive products throughout their lifecycle, from production to delivery.

Installation Process: A Step-by-Step Guide

Installation Process: A Step-by-Step Guide

The installation of custom automotive foam inserts is a precise art that requires attention to detail. It begins with meticulous measuring to ensure the perfect fit for each dashboard component. These foam inserts, designed specifically for shipping fragile automotive parts from Holland, Ohio, are cut to size using advanced techniques, ensuring they snugly accommodate various shapes and contours. Once measured, the installer cleans the dashboard surface, applying a suitable adhesive to create a strong bond. The foam is then carefully positioned, aligning it precisely with the dashboard’s features.

Using specialized tools, the edges of the foam are secured, creating a seamless finish. This process demands patience and skill to avoid damage to both the foam and the dashboard. As the adhesive sets, the final step involves trimming any excess material, resulting in a tailored, protective layer for the automotive parts inside. This guided approach ensures that the custom foam inserts not only enhance the aesthetic appeal but also safeguard valuable components during transit.

Why Select Local Experts: Benefits of Using Holland, Ohio Services

When considering foam inserts for dashboards or protecting fragile automotive parts during shipping in Holland, Ohio, choosing local experts offers a multitude of benefits. Local companies like those based in Holland have an intimate understanding of the regional market and specific needs, ensuring tailored solutions that might be overlooked by broader national providers. They are attuned to local regulations and guidelines regarding packaging and transportation, enhancing compliance and safety.

Moreover, Holland-based businesses often possess advanced equipment and a wealth of experience in crafting custom automotive foam inserts. This capability is invaluable when dealing with unconventional shapes or delicate items. Their proximity allows for faster turnaround times, which is critical for time-sensitive shipments. Additionally, local expertise fosters better communication, ensuring your specific requirements are met precisely, be it special materials for enhanced protection or innovative designs for efficient packing.