CNC machining in Holland, Ohio, creates custom protective foam inserts designed to safeguard delicate electronic components during shipping. These ESD-safe (Electrostatic Discharge) foam solutions minimize waste, offer environmental protection, and provide proper support, reducing damage risk. Specialized businesses use CNC machines to design tailored anti-static foams that act as physical barriers against mechanical impacts and electrical disturbances, ensuring electronics reach their destination intact. Custom foam inserts cater to specific industry needs, incorporating adjustable durometers and densities for optimal shipping crate optimization.

“Revolutionize your shipping crate game with CNC-machined inserts designed specifically for electronic protection. In today’s digital era, securing delicate electronics during transit is paramount, especially in the Columbus, Ohio region. This article explores the role of CNC machining in creating protective foam inserts, enhancing product safety. We delve into customization options, from anti-static foams to ESD (Electrostatic Discharge) safety measures, ensuring your electronics arrive unscathed. Discover how these innovative inserts are transforming the industry and safeguarding valuable components.”

- Understanding CNC Machining and Its Role in Insert Creation

- The Importance of Protective Foam Inserts for Electronics

- Customization Options: Designing Anti-Static Foams for Specific Needs

- ESD Safety: Why It Matters and How Our Inserts Ensure Protection

Understanding CNC Machining and Its Role in Insert Creation

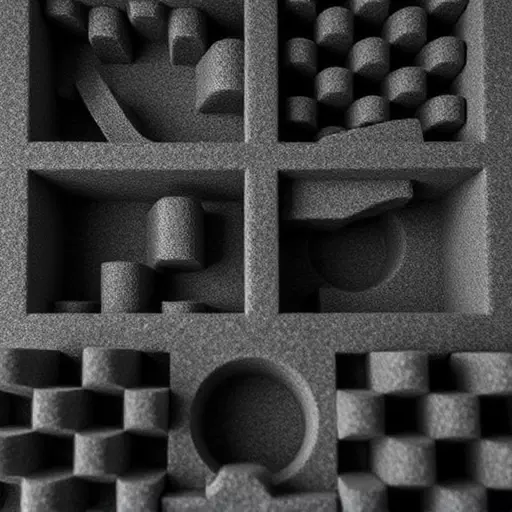

CNC machining is a highly precise and automated process that plays a pivotal role in creating custom protective foam inserts for various industries, especially in the electronics sector. This advanced manufacturing technique allows for the production of intricate designs with minimal waste, making it an ideal method for crafting ESD-safe (Electrostatic Discharge) foam inserts. These specialized inserts are crucial for shipping delicate electronic components, ensuring they reach their destinations without any damage caused by static electricity.

In Holland, Ohio, businesses specializing in custom foam solutions offer tailored protective foam inserts designed to accommodate specific electronics. With the use of CNC machines, they can cut and form anti-static foam materials into precise shapes, creating a secure environment for electronic devices during transit. This level of customization ensures that the sensitive components are not only protected but also properly supported, reducing the risk of damage during shipping.

The Importance of Protective Foam Inserts for Electronics

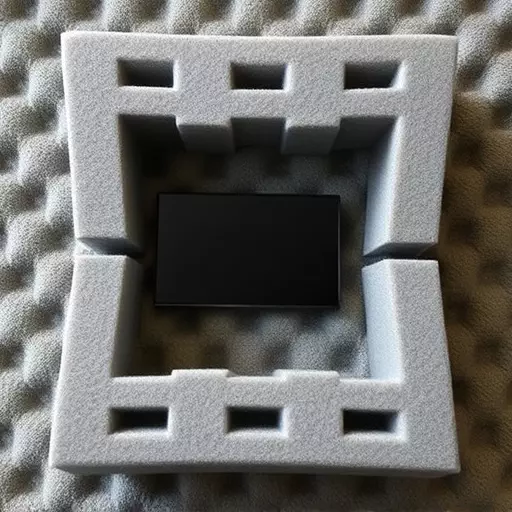

In the realm of electronic shipping and storage, ensuring the safety and integrity of delicate components is paramount. This is where protective foam inserts step in as indispensable tools for packaging professionals, especially those catering to the electronics industry in Holland, Ohio. These custom foam inserts are not just ordinary packing materials; they play a crucial role in safeguarding electronics during transit. By providing an ESD-safe (Electrostatic Discharge) environment, the right foam inserts prevent harmful static shocks that can damage sensitive electronic parts.

Customized to fit shipping crates and boxes, these foam inserts act as a physical barrier and insulation against mechanical impacts and electrical disturbances. Anti-static foam for electronics is designed to dissipate static charges, thus minimizing the risk of electrostatic discharge that could cause irreversible damage to circuits and components. This is particularly vital in industries where even minor static shocks can compromise product quality and functionality.

Customization Options: Designing Anti-Static Foams for Specific Needs

When it comes to shipping electronic components, customization is key to ensuring safe and secure delivery. That’s where CNC-machined inserts excel, offering a range of options for specialized protective foam inserts for electronics in Holland, Ohio. Businesses can collaborate with manufacturers to design custom foam inserts tailored to their unique requirements. This level of personalization is especially critical when transporting delicate items that require specific anti-static or ESD-safe (Electrostatic Discharge) protection.

For example, CNC machining allows the creation of intricate foam shapes capable of securely cradling sensitive electronics, preventing movement during transit and reducing the risk of damage. Anti-static foams can be engineered with specific durometers and densities to accommodate various product sizes and weight distributions. This customization ensures that each shipping crate is optimized for its intended contents, providing a safe haven for electronics in every stage of their journey from manufacturer to end user.

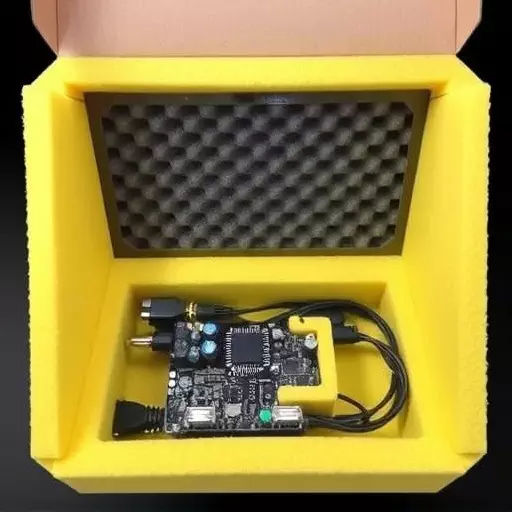

ESD Safety: Why It Matters and How Our Inserts Ensure Protection

In the manufacturing and shipping of electronic components, ESD (Electrostatic Discharge) safety is paramount to prevent damage and ensure product integrity. Our CNC-machined protective foam inserts for electronics in Holland, Ohio, are specifically designed with this in mind. We utilize specialized materials that act as an anti-static barrier, preventing the build-up of static electricity that can harm sensitive electronics during transit. Unlike generic foam, our custom foam inserts incorporate ESD-safe foams that absorb and dissipate electrostatic charges, safeguarding your valuable cargo from potential damage.

Whether you require standard or customized configurations for unique packaging needs, our foam inserts offer a reliable solution. We take pride in providing high-quality products that meet the stringent requirements of electronics manufacturers, ensuring the safe delivery of components across various industries.