Pavement milling and grinding are essential processes for maintaining Toledo, Ohio's roadways, effectively addressing issues like potholes and cracks. These techniques involve removing damaged asphalt or concrete with specialized machines before smoothing the surface for repair. Toledo utilizes advanced laser guidance systems to ensure precise removal, enabling targeted repairs that preserve road integrity and extend service life. The city's approach to crack repair using these methods minimizes traffic disruptions while offering a durable and cost-effective solution. By focusing on repairing only damaged layers rather than entire roads, Toledo's strategy accelerates the repair process, reduces material usage, and cuts costs, all the while enhancing road safety and sustainability. The successful application of pavement milling and grinding in Toledo demonstrates its role as a key modern repair strategy for urban infrastructure maintenance.

When roadways bear the brunt of time and traffic, cracks emerge, posing a risk to drivers and vehicles alike. Pavement milling and grinding play a pivotal role in addressing these issues, particularly in Toledo, Ohio, where infrastructure maintenance is not just about safety—it’s an art honed over years. This article delves into the intricacies of this process, showcasing how advanced techniques are revolutionizing crack repair on Toledo roadways. Join us as we explore the transformative impact of pavement milling and grinding, a method that goes beyond mere repair to restore the integrity and longevity of our city’s infrastructure.

- Pavement Milling and Grinding: An Overview of the Process in Toledo, Ohio

- The Role of Advanced Techniques in Crack Repair via Milling and Grinding

- Case Study: Successful Implementation of Milling for Crack Repair on Toledo Roadways

Pavement Milling and Grinding: An Overview of the Process in Toledo, Ohio

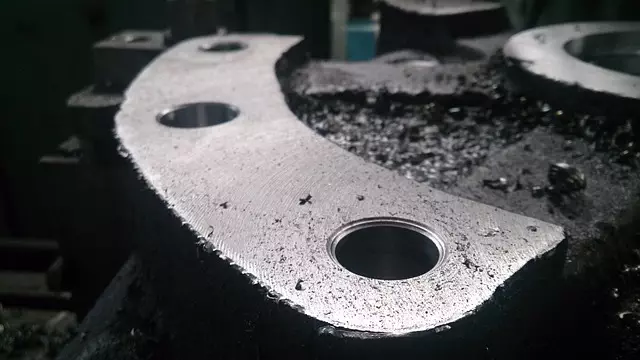

Pavement milling and grinding serve as indispensable processes in the maintenance and repair of roadways, with Toledo, Ohio being no exception. The process of pavement milling involves the precise removal of specified depths of asphalt or concrete from a road surface using specialized machinery known as milling machines. This operation is crucial for various reasons, including preparing the surface for repairs, resurfacing, or reconstruction. In Toledo, Ohio, this method is employed to address issues such as potholes, cracks, and other surface irregularities that can compromise the integrity of the road and endanger drivers.

The grinding phase follows milling and involves smoothing out the newly exposed layer of subgrade or base material. The machinery utilized in this step grinds down any rough edges left by the milling process, ensuring a seamless and even surface for the application of new asphalt or concrete layers. In Toledo’s context, this meticulous process is part of the city’s ongoing efforts to maintain its infrastructure. The combination of pavement milling and grinding in Toledo, Ohio, is a testament to the city’s commitment to safety and efficiency in road repairs. These operations are conducted with precision and care to minimize disruptions and restore traffic flow as quickly as possible while ensuring long-lasting and durable road surfaces.

The Role of Advanced Techniques in Crack Repair via Milling and Grinding

In the realm of infrastructure maintenance, pavement milling and grinding play a pivotal role in effectively addressing cracks within road surfaces. This process involves the precise removal of damaged asphalt or concrete to prepare for repairs. Advanced techniques in pavement milling and grinding have significantly enhanced the efficiency and quality of crack repair work. These advancements include the integration of sophisticated machinery equipped with laser guidance systems, which ensure accurate cuts and minimal disruption to surrounding materials. The precision of these tools allows for targeted repairs that address the specific issues without compromising the integrity of the remaining pavement structure.

Furthermore, the skillful application of milling and grinding techniques by experts in Toledo, Ohio, exemplifies the high standards of workmanship required for successful crack repair. The use of advanced machinery not only streamlines the repair process but also contributes to a more durable and long-lasting fix. In Toledo, these methods are applied with a keen understanding of local pavement conditions, ensuring that each intervention is tailored to the unique challenges presented by the area’s infrastructure. This combination of advanced technology and local expertise ensures that the repairs performed through pavement milling and grinding stand as a testament to the effectiveness of modern repair techniques in extending the lifespan of our roadways.

Case Study: Successful Implementation of Milling for Crack Repair on Toledo Roadways

The city of Toledo, Ohio, has successfully implemented pavement milling and grinding as a solution for crack repair in its roadways, showcasing an effective approach to infrastructure maintenance. This method involves precision removal of the damaged surface course, allowing for the replacement of the compromised material with fresh asphalt or concrete. In recent projects along Toledo’s road network, pavement milling and grinding were employed to address a network of cracks that had developed over time due to thermal expansion, traffic load, and subgrade settling. The meticulous process ensures minimal disruption to traffic flow while effectively treating the underlying issues. The removal of only the defective layer, as opposed to the entire road structure, not only accelerates the repair process but also significantly reduces material usage and associated costs. The result is a refined surface that not only extends the lifespan of the road but also enhances safety for drivers and pedestrians alike. This successful implementation of pavement milling and grinding in Toledo serves as a benchmark for urban infrastructure maintenance, demonstrating the viability and efficiency of this advanced repair technique.