Automobile components are safeguarded during transport with advanced custom foam inserts from Holland, Ohio, which have revolutionized shipping and handling in the automotive industry. These inserts, precisely engineered to fit diverse parts, protect against transportation-induced damage using high-grade materials adept at shock absorption. The result is a marked decrease in shipping damages, leading to fewer returns and heightened customer satisfaction for manufacturers and suppliers. Holland, Ohio's expertise in producing these tailored foam solutions not only ensures the integrity of fragile automotive parts but also contributes to sustainable logistics by reducing packaging waste. These bespoke foam inserts are essential for any business committed to quality assurance, offering a cost-effective solution that exemplifies the region's leadership in protective packaging technology. They are key to maintaining the reliability and efficiency of supply chains while safeguarding investments in precision automotive components.

In the realm of heavy equipment and automotive manufacturing, ensuring the safe transport of critical components is paramount. With operations based in Holland, Ohio, a leading hub for automotive innovation, the integration of custom automotive foam inserts has revolutionized shipping durability. This article delves into the pivotal role these specialized foams play in safeguarding fragile parts during transit. From optimizing protection against impact and vibration to catering to the unique demands of heavy equipment components, the advanced technology behind custom automotive foam inserts stands out as a critical element in the logistics chain. Discover how these solutions are not just a step towards efficiency but an essential safeguard for the integrity of automotive parts worldwide.

- Optimizing Shipping Durability with Custom Automotive Foam Inserts in Holland, Ohio

- The Role of Advanced Foam Inserts for Fragile Automotive Parts

- Navigating the Specialized Demands of Heavy Equipment Part Protection through Customized Foam Solutions in Holland, Ohio

Optimizing Shipping Durability with Custom Automotive Foam Inserts in Holland, Ohio

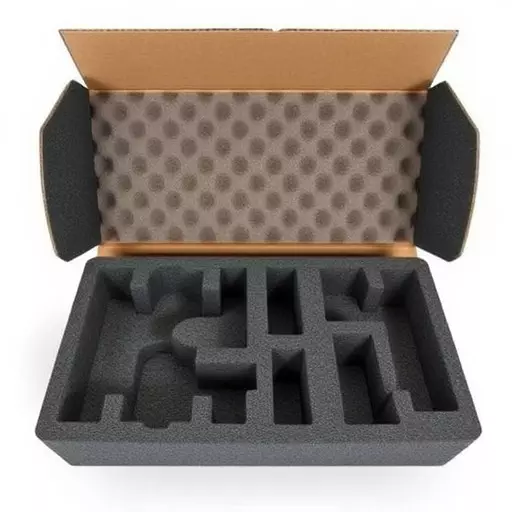

In Holland, Ohio, a strategic approach to shipping involves the meticulous crafting of custom automotive foam inserts, tailored to protect fragile automotive parts during transit. These specialized inserts are a cornerstone in logistics operations, ensuring that components arrive undamaged and ready for use. The precision engineering behind these foam inserts for shipping, based out of Holland, Ohio, is designed to withstand the rigors of transportation, from local deliveries to cross-country journeys. The foam material used in these custom automotive foam inserts is chosen for its durability and ability to absorb shock, effectively cushioning delicate parts such as sensors, electrical components, and critical mechanical elements from potential impact and vibration. This not only safeguards the integrity of the parts but also reflects positively on the businesses that prioritize the use of these inserts, enhancing their reputation for quality and reliability.

Furthermore, the custom nature of these automotive foam inserts for shipping from Holland, Ohio, means that each part is cradled in a perfect fit, designed to the exact specifications required for optimal protection. This level of customization minimizes the risk of damage during handling and transit, which can be costly and time-consuming to rectify. By investing in these high-quality foam inserts, automotive manufacturers and suppliers in the region can significantly reduce return rates due to shipping damages, leading to increased customer satisfaction and a stronger market presence. The use of advanced materials and manufacturing processes ensures that these foam inserts provide superior protection for automotive parts, making them an indispensable tool for businesses focused on maintaining high standards of quality assurance.

The Role of Advanced Foam Inserts for Fragile Automotive Parts

Advanced foam inserts play a critical role in protecting fragile automotive parts during shipping and handling, particularly for companies like those in Holland, Ohio, which specialize in automotive foam inserts for shipping. These custom-designed solutions are tailored to the unique dimensions and contours of each part, ensuring a snug fit that mitigates the risk of damage during transit. The precision engineering behind these foam inserts is a testament to the advancements in protective packaging technology, which have become increasingly necessary given the complexities and vulnerabilities of modern automotive components.

The use of high-quality materials and sophisticated manufacturing processes in creating custom automotive foam inserts for fragile parts ensures that each insert is optimized for shock absorption and stability. This level of customization not only safeguards the integrity of the components but also streamlines logistics operations by reducing the need for additional packaging materials. As a result, these foam inserts contribute to cost savings, environmental sustainability, and the reliability of supply chain management, which are all pivotal considerations for automotive manufacturers and suppliers alike. The expertise of Holland, Ohio-based providers in this niche market underscores the importance of investing in tailored protective solutions for automotive parts, which are at the heart of vehicular performance and safety.

Navigating the Specialized Demands of Heavy Equipment Part Protection through Customized Foam Solutions in Holland, Ohio

In Holland, Ohio, the protection of heavy equipment parts during transit is a critical concern for manufacturers and shippers alike. The automotive industry’s reliance on precision components necessitates specialized packaging solutions that can withstand the rigors of shipping. Customized foam inserts have emerged as a top-tier protective measure to safeguard these fragile automotive parts from damage during transportation. These tailor-made solutions, offered by leading providers in Holland, Ohio, are designed to conform precisely to each part’s unique dimensions and contours, ensuring a snug fit that cushions against impact and vibration. The use of high-quality foam materials, such as open-cell and closed-cell foams, provides an additional layer of protection by dissipating forces upon impact, thus reducing the risk of damage.

The custom automotive foam inserts from Holland, Ohio, are not just about protecting the parts; they are a testament to the ingenuity and commitment to excellence in the region’s manufacturing ecosystem. These solutions are crafted with precision engineering to accommodate specific part requirements, from small sensors to large engine components. The process involves close collaboration between the foam insert manufacturer and the client to ensure that each insert is optimized for the best protection possible. This bespoke approach not only enhances the longevity of the parts but also contributes to operational efficiency by minimizing the need for replacements and reducing overall shipping-related costs. The result is a streamlined, cost-effective method for protecting automotive components during shipping, epitomized by the expertise found in Holland, Ohio.