Pavement milling and grinding plays a critical role in maintaining Toledo, Ohio's road infrastructure by enhancing drainage systems and ensuring the longevity of roadways. In 2021, Toledo's Department of Transportation utilized this process to address aging infrastructure and weather-related damage, recycling the removed asphalt into new pavement materials, thereby supporting sustainable construction practices. The precise removal of asphalt layers to specified depths not only prepares the roadbed for resurfacing but also improves the adherence of new layers, leading to safer and more durable roads over time. This method promotes effective water flow, which is essential for preventing drainage issues. The city's commitment to pavement milling and grinding exemplifies an eco-friendly approach to infrastructure maintenance, with minimal landfill use and a focus on long-term roadway sustainability. Pavement milling and grinding in Toledo, Ohio, serves as a model for urban infrastructure management, emphasizing the importance of proactive maintenance for the safety and functionality of public roads. This technology advancement has been instrumental in transforming Toledo's drainage systems, reducing future maintenance needs by providing a smooth base for new installations and promoting efficient water flow into them. Keywords include "pavement milling and grinding" and "pavement milling and grinding Toledo Ohio."

explored through “Pavement Milling and Grinding: Enhancing Drainage for Better Infrastructure,” this article delves into the transformative role of pavement milling and grinding in improving drainage systems. Beginning with a comprehensive overview of the process, its mechanical benefits, and environmental advantages, we then focus on a real-world application through a case study highlighting Toledo, Ohio’s innovative approach to this method. Finally, we examine how recent advancements in pavement milling and grinding techniques specifically contribute to more effective drainage solutions, ensuring safer and more efficient roadways for communities nationwide.

- Pavement Milling and Grinding: An Overview of the Process and Its Benefits

- Case Study: Pavement Milling and Grinding Operations in Toledo, Ohio

- The Impact of Advanced Pavement Milling and Grinding Techniques on Drainage Improvement

Pavement Milling and Grinding: An Overview of the Process and Its Benefits

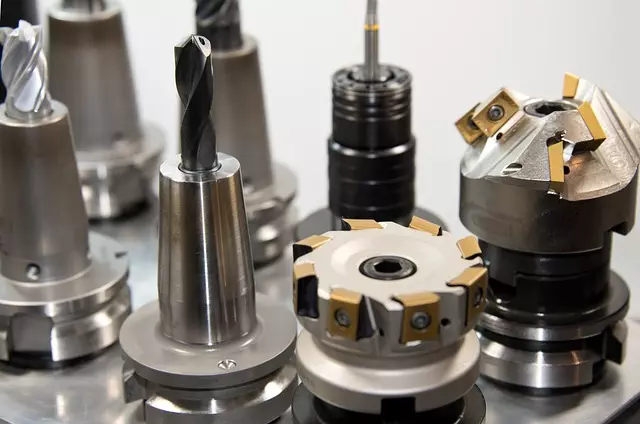

Pavement milling and grinding are essential processes in road maintenance and construction, playing a pivotal role in drainage improvement. These techniques involve the removal of the surface course of asphalt pavement to various depths using specialized machinery. The process begins with setting up traffic control measures to ensure safety for both workers and motorists. A milling machine then carefully removes the specified layer of the pavement, which can range from one inch to nearly the full depth of the pavement structure. This equipment consists of a rotating drum equipped with teeth or picks that grind the asphalt into manageable pieces, which are subsequently collected and recycled into new pavement materials.

The benefits of pavement milling and grinding in Toledo, Ohio, and elsewhere are manifold. Not only does it provide a clean and smooth surface for drivers, but it also facilitates improved water drainage. By precisely controlling the depth of milling, contractors can correct deficiencies in the pavement structure that may impede effective water flow. This process is particularly useful in preparing roadways for resurfacing or reconstruction work. It ensures that the new layers of asphalt will adhere properly and that the road will be safer and more durable over time. Moreover, the recycling aspect of pavement milling supports sustainable construction practices by reducing the need for new materials and minimizing landfill use. This makes it an environmentally friendly solution for maintaining and upgrading infrastructure while promoting longevity and safety on our roadways.

Case Study: Pavement Milling and Grinding Operations in Toledo, Ohio

In Toledo, Ohio, pavement milling and grinding operations have become a critical component in the city’s infrastructure maintenance and drainage improvement initiatives. These operations involve the precise removal of the asphalt layer from existing roadways to various depths, a process essential for both repair and resurfacing projects. The ground-down material is then processed and reused in new pavement construction, exemplifying an environmentally sustainable approach. This method not only ensures a consistent surface for vehicular traffic but also facilitates the installation of improved drainage systems beneath. In 2021 alone, Toledo’s Department of Transportation conducted extensive milling and grinding operations as part of a larger plan to overhaul its roadways, which were adversely affected by aging infrastructure and weather-related damage. The outcomes of these efforts have been multifaceted, providing not only immediate benefits in terms of drainage but also laying the groundwork for future enhancements to Toledo’s transportation network. The pavement milling and grinding activities in Toledo serve as a case study for effective urban infrastructure management, demonstrating how strategic maintenance can significantly contribute to both safety and efficiency on public roadways.

The Impact of Advanced Pavement Milling and Grinding Techniques on Drainage Improvement

Advanced pavement milling and grinding techniques have significantly enhanced the efficiency and quality of drainage improvement projects. Pavement milling and grinding, a process whereby concrete or asphalt surfaces are precisely ground down to a specified depth, plays a crucial role in preparing the substrate for new drainage systems. In Toledo, Ohio, for instance, this method has been instrumental in addressing the city’s aging infrastructure. The precision of modern milling machines allows for the removal of only the damaged or worn-out layers, preserving the structural integrity of the pavement while creating a smooth and even surface for the installation of new drainage solutions. This targeted approach minimizes disruption to traffic flow and reduces material waste, making it an environmentally friendly option. Furthermore, the accuracy of these techniques ensures that water can effectively flow into the newly installed drainage systems, significantly improving the overall drainage capacity of the area. The benefits extend beyond immediate repairs; the improved drainage contributes to the longevity of the repaired pavement and adjacent infrastructure, ensuring safer travel conditions and reducing the need for frequent maintenance.