Holland Ohio has set a new standard in the packaging industry with its innovative application of CNC machining technology. By creating custom CNC-machined packaging components, particularly for steel racks used in long-distance shipping, the company addresses key challenges such as durability and protection during transit. The precision and versatility of CNC machining have led to significant advancements in the design and production of packaging components, resulting in reduced risks of transit damage, enhanced structural integrity, and cost savings. These benefits are underscored by Holland Ohio's streamlined production process, which not only improves quality and functionality but also supports environmental efficiency. The company's expertise in CNC machining for the packaging industry offers tailored solutions that maintain product integrity under various shipping conditions, thus redefining the benchmark for durable and efficient packaging design. Their commitment to innovation using advanced CNC machining positions Holland Ohio as a leader in providing sustainable and cost-effective packaging solutions within the logistics sector.

In the logistics sector, the integrity of goods during long-distance shipping is paramount. Holland Ohio, a leader in the field, has innovatively leveraged CNC machining for the packaging industry to enhance the durability and performance of steel racks. This article delves into the transformative impact of custom CNC-machined packaging components, highlighting their role in fortifying steel racks for arduous shipping journeys. By exploring the advantages of CNC machining in the packaging sector, including its contributions to strength and reliability, we uncover how Holland Ohio’s precision engineering sets a new standard for secure transport solutions. Join us as we examine a case study showcasing their cutting-edge approach to steel rack durability through advanced CNC machining techniques.

- Optimizing Long-Distance Shipping with CNC Machining for Packaging Industry: Holland Ohio Leads the Way

- The Role of Custom CNC-Machined Packaging Components in Enhancing Durability for Steel Racks

- Advantages of CNC Machining in the Packaging Sector: Strength and Reliability for Shipping Operations

- Case Study: Holland Ohio's Innovative Approach to Durable Steel Racks through Precision CNC Machining

Optimizing Long-Distance Shipping with CNC Machining for Packaging Industry: Holland Ohio Leads the Way

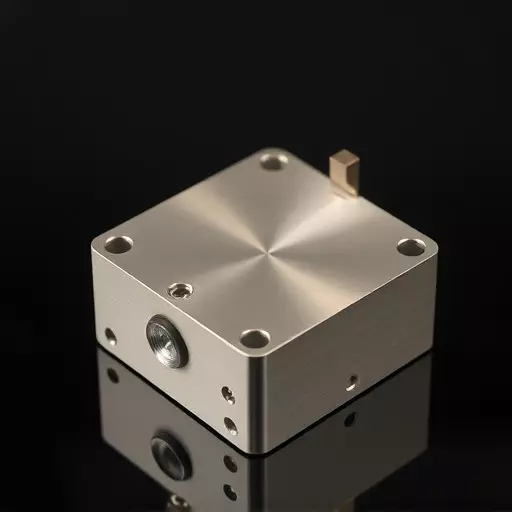

In the realm of long-distance shipping, the packaging industry faces unique challenges that require innovative solutions to ensure the safety and integrity of products during transit. Holland Ohio, a leading provider of custom CNC-machined packaging components, has set a precedent in optimizing this critical supply chain link. By leveraging computer numerical control (CNC) machining technology, Holland Ohio manufactures packaging solutions that are precise, durable, and tailored to the specific needs of their clients’ products. This advanced manufacturing process allows for the creation of custom-shaped and sized components, which can be particularly beneficial when dealing with items that require a snug fit or complex geometries. The precision of CNC machining ensures that each package is designed to protect its contents from the rigors of long-distance shipping, minimizing the risk of damage or loss.

The advantages of integrating CNC machining in the packaging industry are manifold. Holland Ohio’s commitment to this technology has not only streamlined their production process but also significantly improved the quality and functionality of the packaging components they produce. The repeatability and accuracy of CNC machining translate into consistent packaging performance, which is paramount when products are transported over vast distances. This reliability reduces waste and the need for additional materials, contributing to cost savings and a lower environmental impact. Moreover, the bespoke nature of these components means that they can be designed to withstand specific environmental conditions encountered during shipping, such as temperature fluctuations, moisture, or rough handling. As a result, Holland Ohio’s innovative approach to packaging design using CNC machining is setting a new industry standard, ensuring that goods arrive at their destination in the same condition as when they were dispatched.

The Role of Custom CNC-Machined Packaging Components in Enhancing Durability for Steel Racks

In the realm of long-distance shipping, the integrity and durability of steel racks are paramount to protect goods during transit. The use of custom CNC-machined packaging components plays a pivotal role in enhancing the longevity and performance of these racks. Companies like those in Holland, Ohio, specialize in the precise art of CNC machining for packaging industry applications. These tailor-made parts are engineered to fit seamlessly with steel rack structures, providing superior support and stability. The precision afforded by CNC machining ensures that each component is crafted to exact dimensions, resulting in a more robust and reliable assembly. This meticulous approach not only minimizes the risk of damage during transit but also contributes to the overall efficiency of loading and unloading operations.

The benefits of incorporating custom CNC-machined packaging components into steel racks are manifold. For one, the material strength and fitment accuracy reduce the likelihood of in-transit mishaps, such as shifting or falling cargo. Additionally, these precision-engineered parts can be designed to withstand harsh environmental conditions, extending the usable life of the racks. The use of advanced CNC machining technology allows for rapid prototyping and iteration, enabling continuous improvement in packaging solutions. This adaptability ensures that steel rack systems can evolve alongside changing industry standards and shipping demands, guaranteeing long-term reliability and efficiency.

Advantages of CNC Machining in the Packaging Sector: Strength and Reliability for Shipping Operations

In the packaging sector, the integration of CNC machining has significantly advanced the capabilities of steel rack manufacturing, particularly for long-distance shipping applications. Holland Ohio and its industrial counterparts have harnessed the precision and efficiency of custom CNC-machined packaging components to enhance durability and reliability in shipping operations. The benefits of CNC machining in the packaging industry are manifold. Firstly, CNC machining ensures that each steel rack component is crafted with high precision and repeatability, which is crucial for creating structures that can withstand the rigors of transit without compromising the integrity of the goods being shipped. This level of accuracy translates to a robust framework, capable of securely housing items across vast distances, even under challenging conditions.

Moreover, the use of CNC machining for packaging industry applications in Holland Ohio has led to significant advancements in both strength and versatility. The ability to quickly produce custom designs allows businesses to tailor their packaging solutions to meet specific needs, whether it be for heavy-duty industrial equipment or sensitive electronics. The benefits of this technology extend beyond the immediate product; they also encompass the sustainability of operations. By minimizing waste and optimizing material usage, CNC machining contributes to a more environmentally friendly packaging process, which is increasingly important in today’s eco-conscious marketplace. This commitment to both performance and environmental responsibility positions the packaging industry as a leader in adopting innovative manufacturing techniques like CNC machining, thereby setting a new standard for shipping operations worldwide.

Case Study: Holland Ohio's Innovative Approach to Durable Steel Racks through Precision CNC Machining

Holland Ohio, a leading manufacturer in the packaging industry, has set a benchmark for excellence with its innovative approach to durable steel racks designed for long-distance shipping. Utilizing advanced CNC machining technology, Holland Ohio crafts custom cnc-machined packaging components that are both robust and precise. This strategic application of CNC machining for the packaging industry not only enhances the durability of the racks but also ensures they meet the stringent demands of handling, stacking, and securing products during transit.

The benefits of integrating CNC machining in the packaging process are manifold. It allows for precise dimensions and repeatable accuracy that are critical for the integrity of the steel racks. This precision significantly reduces waste and the need for extensive assembly, which translates to cost savings and a more sustainable production practice. Moreover, these custom components can be tailored to specific client needs, ensuring that each rack is optimized for the unique requirements of long-distance shipping. Holland Ohio’s commitment to innovation in CNC machining has set a new standard for durability, efficiency, and performance in packaging solutions.