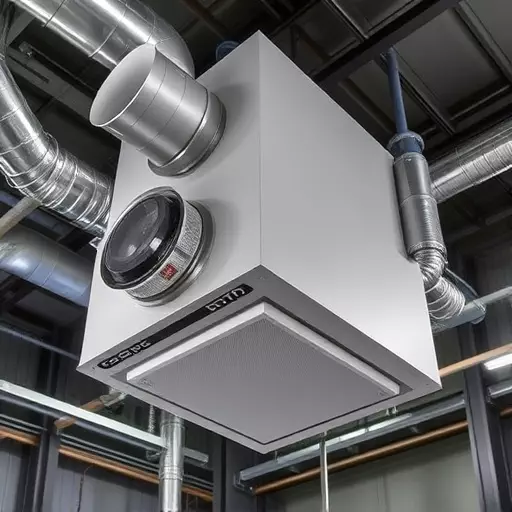

Industrial ventilation solutions, focusing on both exhaust and supply systems, are powerful tools for achieving significant energy savings in manufacturing and industrial facilities. By optimizing air movement, these solutions reduce reliance on heating and cooling systems while maintaining high indoor air quality and temperature control. Key features include advanced technologies like smart sensors, high-efficiency filters, and variable speed drives, enabling real-time adjustments to ventilation rates based on occupancy and temperature. Strategic design of supply ventilation systems ensures effective contaminant removal at source, contributing to a greener industrial landscape. Integrating these solutions can lead to substantial energy savings, improved worker productivity, and enhanced sustainability, especially in large facilities where proper ventilation management is crucial.

In today’s quest for energy efficiency, industrial ventilation plays a pivotal role. Understanding and optimizing ventilation systems can lead to significant cost savings and environmental benefits. This article explores various facets of ventilation energy efficiency, focusing on industrial applications. From industrial ventilation solutions to exhaust ventilation solutions and supply ventilation systems, each section delves into strategies to enhance air flow while minimizing energy loss. Discover how smart controls, sensors, and real-world case studies are revolutionizing the landscape of industrial ventilation solutions.

- Understanding Ventilation Energy Efficiency: The Basis for Industrial Savings

- Industrial Ventilation Solutions: Optimizing Exhaust Systems

- Exhaust Ventilation Solutions: Key to Energy-Efficient Processes

- Supply Ventilation Systems: Ensuring Adequate Air Flow with Minimal Energy Loss

- Integrating Smart Controls and Sensors for Enhanced Ventilation Efficiency

- Case Studies: Real-World Success Stories in Industrial Ventilation Energy Conservation

Understanding Ventilation Energy Efficiency: The Basis for Industrial Savings

Understanding Ventilation Energy Efficiency is a cornerstone for achieving significant energy savings in industrial settings. By optimizing air movement within buildings, organizations can reduce their reliance on heating and cooling systems, leading to substantial cost reductions. Industrial ventilation solutions play a pivotal role here; they ensure that supply ventilation systems and exhaust ventilation solutions work harmoniously to maintain optimal indoor environments while minimizing energy consumption.

Efficient ventilation systems consider the unique needs of industrial processes, managing air quality, temperature control, and safety standards. By employing advanced technologies, such as smart sensors and optimized fans, these systems can adapt to real-time demands. This adaptability results in more precise climate control, eliminating energy wastage and contributing to a greener, more sustainable industrial landscape.

Industrial Ventilation Solutions: Optimizing Exhaust Systems

Industrial ventilation solutions play a pivotal role in enhancing energy efficiency across various manufacturing and industrial facilities. Optimizing exhaust ventilation systems is a game-changer, enabling significant cost savings while improving working conditions. By employing advanced technologies, such as high-efficiency filters and variable speed drives, these systems can ensure that air is expelled effectively without compromising the interior environment.

Effective exhaust ventilation solutions involve strategic design and implementation of supply ventilation systems. This includes carefully considering factors like building layout, equipment placement, and environmental regulations. Modern industrial ventilation systems are designed to capture and remove contaminants at their source, reducing the overall energy load required for ventilation. As a result, organizations can achieve better indoor air quality, enhance worker productivity, and contribute to a more sustainable operational footprint.

Exhaust Ventilation Solutions: Key to Energy-Efficient Processes

In the pursuit of energy efficiency, exhaust ventilation solutions play a pivotal role in industrial settings. By effectively removing stale air and extracting heat, these systems contribute significantly to reduced energy consumption. Modern industrial ventilation solutions often incorporate advanced technologies like high-efficiency filters and optimized fans, ensuring optimal airflow while minimizing power usage. This is particularly crucial in processes that generate significant heat or require precise environmental conditions.

Exhaust ventilation systems are not just about removal; they form a critical component of overall building or facility management. Integrating these solutions with supply ventilation systems creates a balanced exchange of air, maintaining indoor air quality and comfort without unnecessary energy expenditure. This strategic approach to industrial ventilation not only enhances operational efficiency but also aligns with sustainability goals by reducing the carbon footprint associated with energy-intensive processes.

Supply Ventilation Systems: Ensuring Adequate Air Flow with Minimal Energy Loss

Supply ventilation systems play a vital role in maintaining indoor air quality and comfort while optimizing energy efficiency. These industrial ventilation solutions ensure that fresh air is delivered to occupied spaces, replacing stale or contaminated air with minimal energy loss. Unlike exhaust ventilation solutions that focus on removing warm air and pollutants, supply systems prioritize the introduction of cool, clean air from external sources or recycled indoor air after filtering.

By carefully designing and implementing these systems, buildings can achieve better thermal comfort and reduced energy consumption. Advanced technologies, such as variable-speed fans and smart control systems, enable precise control over airflow rates, ensuring optimal performance during different occupancy levels and environmental conditions. This results in significant energy savings without compromising on the health and well-being of occupants, making supply ventilation systems a key component in modern, sustainable building design.

Integrating Smart Controls and Sensors for Enhanced Ventilation Efficiency

Integrating smart controls and sensors into ventilation systems is a game-changer for improving energy efficiency in industrial settings. These advanced technologies enable precise control over air movement, ensuring optimal performance across various types of ventilation solutions, including exhaust and supply systems. By utilizing real-time data from sensors, smart controls can automatically adjust ventilation rates based on occupancy, temperature, and other environmental factors, eliminating wasteful energy consumption.

For instance, in industrial facilities with dynamic workloads, smart sensors detect changes in room conditions and respond accordingly by optimizing air extraction or distribution. This proactive approach reduces the reliance on manual adjustments, minimizing human errors and maximizing energy savings. Moreover, integrating these intelligent systems with existing supply ventilation systems can create a more balanced and efficient indoor environment, contributing to overall cost reduction and sustainability goals.

Case Studies: Real-World Success Stories in Industrial Ventilation Energy Conservation

In the pursuit of energy efficiency, case studies from real-world industrial settings offer valuable insights and successful models for ventilation energy conservation. These stories highlight innovative approaches to optimizing air movement in manufacturing plants and other industrial facilities, leading to significant cost savings and environmental benefits. For instance, many plants have adopted advanced exhaust ventilation solutions that not only improve productivity by ensuring optimal working conditions but also reduce energy consumption. By carefully designing these systems, engineers can create a more efficient flow of air, minimizing the energy required for ventilation.

Another common strategy involves integrating supply ventilation systems with smart controls and sensors. These systems adjust airflow based on real-time occupancy and environmental conditions, preventing unnecessary energy usage during off-peak or unoccupied periods. Case studies have shown that implementing such industrial ventilation solutions can result in substantial energy savings while maintaining a safe and comfortable work environment. This approach is particularly effective in large facilities where proper ventilation management can significantly impact overall energy costs.