The article discusses Toledo, Ohio's innovative approach to urban infrastructure maintenance through advanced pavement milling and grinding techniques. These methods are key for extending road longevity, improving performance, and promoting environmental sustainability by reducing waste and conserving resources. Toledo has effectively utilized these techniques to manage its road network efficiently, with minimal disruptions and high accuracy in repairs, positioning itself as a regional leader in sustainable road maintenance. The city's commitment to innovation is evident in its proactive adoption of pavement milling and grinding practices, which facilitate early detection and correction of issues, leading to smoother, more durable roads and serving as a cost-effective solution for municipalities. Toledo's initiative underscores the importance of these techniques, known locally as pavement milling and grinding Toledo Ohio, in enhancing infrastructure and contributing to a greener environment. The city's success in this area demonstrates the significant benefits of employing pavement milling and grinding for road maintenance and rehabilitation.

21st-century urban infrastructure demands resilient and sustainable maintenance practices. This article delves into the intricacies of pavement milling and grinding, highlighting innovative techniques that ensure roadways endure the test of time. We explore Toledo, Ohio’s proactive approach to maintaining its network of streets through this process, showcasing a case study that underscores the benefits of a comprehensive maintenance strategy. Advanced equipment plays a pivotal role in modern operations, and we examine how these technologies enhance efficiency and effectiveness. Additionally, we discuss best practices for implementing milling and grinding projects, ensuring optimal outcomes for urban roadways, as exemplified by Toledo’s initiatives.

- Efficient Pavement Milling and Grinding Techniques for Urban Infrastructure

- Case Study: Pavement Milling and Grinding in Toledo, Ohio – A Comprehensive Approach to Road Maintenance

- The Role of Advanced Equipment in Modern Pavement Milling and Grinding Operations

- Best Practices for Implementing Pavement Milling and Grinding Projects

- Evaluating the Outcomes of Pavement Milling and Grinding on Toledo's Roadways

Efficient Pavement Milling and Grinding Techniques for Urban Infrastructure

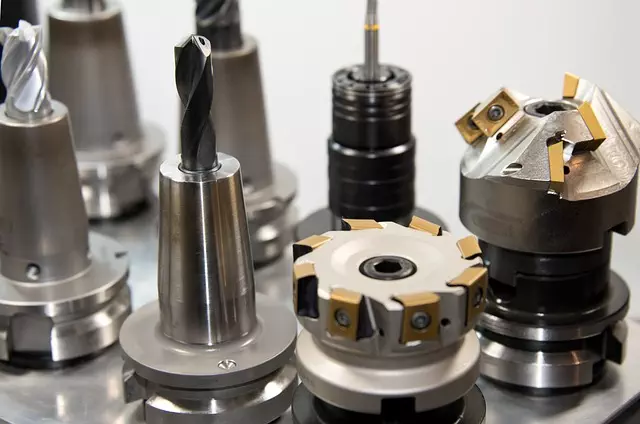

In modern urban infrastructure development and maintenance, efficient pavement milling and grinding techniques play a pivotal role in extending the lifespan and performance of roadways. Pavement milling and grinding are processes that remove the top layer or surface of asphalt or concrete pavements to repair or resurface roads. These techniques not only facilitate the removal of damaged material but also recycle it, leading to environmental sustainability by reducing waste and conserving natural resources. The precision and efficiency of these methods can minimize disruptions in urban areas, allowing for timely maintenance without significant inconvenience to motorists and pedestrians. In Toledo, Ohio, for instance, the deployment of advanced pavement milling and grinding equipment has been instrumental in maintaining the city’s road network. The use of such machinery ensures that the work is conducted with high accuracy and speed, utilizing cutting-edge technology to optimize material recovery and repurposing. This commitment to innovation and efficiency in pavement milling and grinding not only contributes to the longevity and safety of urban infrastructure but also positions Toledo as a leader in sustainable road maintenance practices within its region.

Case Study: Pavement Milling and Grinding in Toledo, Ohio – A Comprehensive Approach to Road Maintenance

Toledo, Ohio, has implemented a strategic approach to pavement rehabilitation by adopting milling and grinding techniques as part of its road maintenance program. This process involves the precise removal of the surface course of an existing roadway, allowing for the inspection and repair of underlying layers. The city’s initiative to incorporate pavement milling and grinding not only extends the lifespan of its roadways but also enhances safety by addressing issues such as potholes and rutting.

The process begins with the precise removal of the top layer of asphalt using specialized equipment. This equipment efficiently mills away the worn surface, exposing the underlying layers for inspection. Any necessary repairs are then carried out before the area is prepared to receive a fresh overlay. The benefits of this method are manifold: it reduces traffic disruptions by minimizing the time needed for repair; it provides a smoother and more durable road surface; and it facilitates the detection and rectification of underlying problems that could lead to future maintenance issues. Toledo’s use of pavement milling and grinding is indicative of a comprehensive, proactive strategy in roadway infrastructure maintenance, setting a precedent for other municipalities to follow.

The Role of Advanced Equipment in Modern Pavement Milling and Grinding Operations

Best Practices for Implementing Pavement Milling and Grinding Projects

Pavement milling and grinding are critical processes in road maintenance and rehabilitation, offering a cost-effective solution for profile removal, surface texture, and pavement preservation. When implementing pavement milling and grinding projects, adherence to best practices ensures the longevity and quality of the pavement surface. One of the key best practices is meticulous planning, which includes a thorough assessment of the project scope, material requirements, and environmental considerations. This phase also involves scheduling the work during optimal conditions to minimize disruptions and maximize efficiency.

In Toledo, Ohio, as with other regions, the success of pavement milling and grinding projects hinges on the use of advanced equipment and trained personnel. The selection of appropriate machinery, such as milling machines and grinding machines, is crucial for achieving precise cuts and smooth finishes. Operators must be skilled in handling these machines to ensure safety and efficiency throughout the project. Additionally, incorporating technology like GPS-guided systems enhances precision and reduces the likelihood of human error. Best practices also emphasize the importance of regular maintenance checks on the equipment to prevent malfunctions and extend the lifespan of the machinery. This proactive approach contributes to a high-quality end product and upholds Toledo’s infrastructure standards.

Evaluating the Outcomes of Pavement Milling and Grinding on Toledo's Roadways

The city of Toledo, Ohio, has undertaken a series of initiatives aimed at enhancing its roadway infrastructure through pavement milling and grinding processes. These techniques are employed to prepare roads for resurfacing or to extend the lifespan of existing pavements by removing surface irregularities and providing a smooth base for overlay applications. The outcomes of these operations have been subject to rigorous evaluation, with focus on their impact on traffic flow, durability, and overall road performance. Data collected post-milling and grinding shows a marked improvement in the ride quality of Toledo’s streets, as evidenced by reduced noise levels and improved skid resistance. These enhancements not only contribute to a safer driving environment but also extend the pavement’s service life, potentially reducing long-term maintenance costs.

Furthermore, the city has leveraged advanced technologies in pavement milling and grinding, ensuring that the debris generated during the process is minimized and efficiently managed. This approach not only supports Toledo’s environmental sustainability goals but also facilitates faster roadway reopenings, as milling operations can be performed quickly with minimal disruption to traffic. The evaluation of these outcomes has been positive, with the city noting a significant reduction in pavement distresses and an overall increase in the structural integrity of its roadways. These results underscore the effectiveness of pavement milling and grinding in Toledo, Ohio, as a cost-effective solution for pavement rehabilitation, contributing to a more reliable and durable transportation network.