Regular kitchen suppression inspections in Spring Lake are essential for fire safety, ensuring systems meet local regulations and are ready to extinguish cooking-related fires promptly. Professionals meticulously assess hoods, nozzles, piping, and installation integrity, testing the system's sensitivity through simulated fires. Post-inspection, immediate action is taken on identified issues, including repairing faulty parts, updating maintenance records, and routine maintenance like checking ventilation ducts and testing agents. These checks are vital for safety, regulatory compliance, and protection of property and occupants.

In the heart of any home, the kitchen poses unique fire hazards. This is where a robust kitchen hood suppression system steps in, crucially mitigating risks and ensuring safety. This article delves into the essential aspects of kitchen suppression systems, their significance, and why regular inspections are paramount for fire safety, especially in Spring Lake. We guide you through the process, from understanding system types to post-inspection measures, empowering homeowners with knowledge for fire suppression compliance checks.

- Understanding Kitchen Suppression Systems: Their Role and Types

- The Importance of Regular Inspection for Fire Safety

- What to Expect During a Kitchen Suppression Inspection in Spring Lake

- Ensuring Compliance: Post-Inspection Steps and Maintenance Tips

Understanding Kitchen Suppression Systems: Their Role and Types

Understanding Kitchen Suppression Systems: Their Role and Types

In any commercial kitchen, a kitchen suppression system stands as a vital safety measure, designed to quickly extinguish fires that may ignite in cooking areas. These systems are part of a comprehensive fire suppression strategy, ensuring compliance with critical fire safety regulations. Spring Lake businesses, in particular, must adhere to stringent fire suppression standards, making regular inspections of these systems paramount. A kitchen suppression system inspection involves evaluating the system’s functionality, components, and readiness to deploy during an emergency.

There are various types of kitchen suppression systems, each tailored to specific cooking methods or kitchen layouts. Wet chemical systems are prevalent, releasing a fine mist of fire-retardant chemicals upon activation. Dry chemical systems, on the other hand, use inert gases like nitrogen to smother fires. In some cases, suppressors combine these technologies for enhanced protection. Regular inspections by certified professionals ensure these systems remain operational and ready, providing peace of mind that your Spring Lake business is fire-suppression compliant.

The Importance of Regular Inspection for Fire Safety

Regular inspections of kitchen hood suppression systems in Spring Lake are non-negotiable for fire safety. These systems play a vital role in mitigating kitchen fires, which can quickly escalate and cause severe damage. A thorough inspection ensures that all components are functioning optimally, identifying any potential issues before they become hazardous. It’s akin to maintaining a life support system—a periodic check-up is essential to guarantee its reliability when it matters most.

Fire suppression compliance checks should be an integral part of your property maintenance routine. Ignoring these inspections can lead to costly repairs or worse, a fire emergency that could have been prevented. By keeping up with these checks, Spring Lake residents and business owners can rest assured their kitchen hood systems are prepared to suppress fires, protecting lives, property, and investments.

What to Expect During a Kitchen Suppression Inspection in Spring Lake

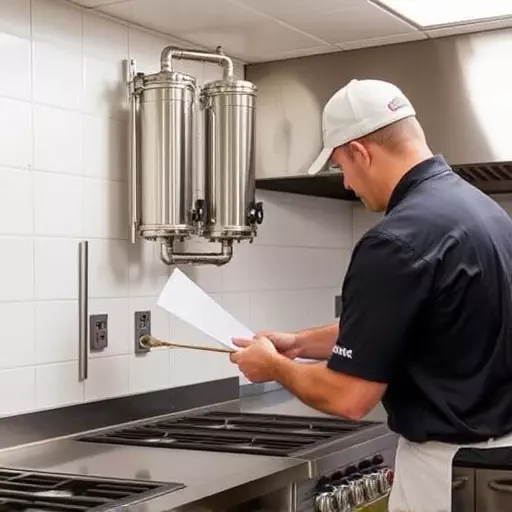

During a Kitchen Suppression Inspection in Spring Lake, you can expect a thorough evaluation of your kitchen’s fire suppression system. The inspection typically involves a professional examining the entire setup to ensure it complies with local fire safety regulations. This includes checking the condition and functionality of the hood, fire suppression nozzles, and associated piping. The inspector will verify that all components are properly installed, maintained, and up to code. They’ll also assess the system’s readiness to activate in case of a kitchen fire, ensuring rapid suppression to minimize damage and keep your Spring Lake residence safe.

Additionally, the inspection may cover testing procedures to guarantee the system’s sensitivity and reliability. This might involve simulating a fire scenario to see how the hood responds, checking for any leaks or defects, and reviewing maintenance records. The goal is to identify potential issues early on, allowing you to address them promptly and maintain optimal fire suppression compliance checks.

Ensuring Compliance: Post-Inspection Steps and Maintenance Tips

After a thorough kitchen suppression inspection in Spring Lake, it’s crucial to ensure all identified issues are addressed promptly for fire suppression compliance. The post-inspection process involves reviewing the system’s performance and functionality, repairing or replacing faulty components, and updating maintenance records. Regular, scheduled inspections are vital to maintaining optimal safety standards, as they allow for early detection of potential problems.

To keep your kitchen suppression system in top condition, implement routine maintenance tips such as inspecting ventilation ducts for leaks or blockages, testing fire suppression agents regularly, and ensuring all equipment is properly calibrated. Staying proactive not only complies with fire regulations but also safeguards your property and those within it from potential hazards.