Custom-molded EPP foam from Holland, Ohio, offers innovative and sustainable packaging for diverse industries. With superior shock absorption, lightweight design, and cost-effectiveness, it's ideal for protecting fragile items while reducing shipping costs. Its versatility allows for intricate shapes, ensuring perfect product security. Choose this eco-friendly solution for optimal protection and market alignment.

Custom-molded foam inserts are revolutionizing product packaging, offering unparalleled protection and versatility. This article delves into the world of these innovative solutions, highlighting the benefits of expanded polypropylene (EPP) foam packaging. We explore how lightweight EPP molded foam packaging from Holland, Ohio, provides efficient and sustainable alternatives. Learn about choosing the right insert for your needs, ensuring optimal product security and customer satisfaction. Discover why these custom foams are gaining popularity across various industries as top-tier packing materials.

- What are Custom-Molded Foam Inserts?

- Benefits of Using Expanded Polypropylene (EPP) Foam Packaging

- Lightweight EPP Molded Foam Packaging: A Solution from Holland, Ohio

- How to Choose the Right Foam Insert for Your Product Packaging

What are Custom-Molded Foam Inserts?

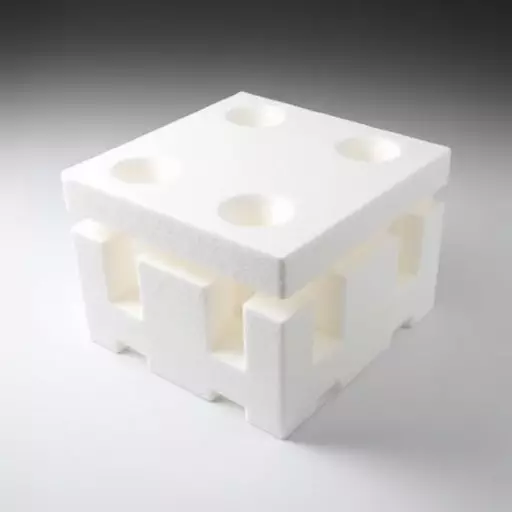

Custom-molded foam inserts are innovative packaging solutions that offer a multitude of benefits for various industries. These inserts are created by molding lightweight Expanded Polypropylene (EPP) foam into unique shapes and sizes to fit specific product requirements. With a base in Holland, Ohio, manufacturers produce these custom-molded foam inserts using advanced techniques, ensuring precise dimensions and superior protection for delicate items.

The advantages of EPP foam packaging are numerous. It provides excellent shock absorption, making it ideal for protecting fragile goods during transit. Moreover, its lightweight nature reduces shipping costs and environmental impact, a significant factor in today’s eco-conscious market. Customized foam inserts can be designed to perfectly accommodate products, maximizing space utilization while minimizing material waste, thus offering both economic and ecological benefits.

Benefits of Using Expanded Polypropylene (EPP) Foam Packaging

Custom-molded foam inserts made from Expanded Polypropylene (EPP) offer a plethora of benefits for packaging and protection, making them a popular choice among many industries. One of the key advantages is their lightweight nature; EPP is approximately 95% air, which makes it an ideal material for reducing overall package weight without compromising structural integrity. This feature is particularly valuable in shipping and transportation, where minimizing cargo weight can lead to significant cost savings.

Additionally, EPP foam provides exceptional shock absorption and impact resistance, making it excellent for protecting fragile items during transit. Its rigid yet flexible structure allows it to conform to the shape of various products, ensuring they remain secure and undamaged. Moreover, EPP is known for its durability and long-lasting performance, making it a sustainable choice as it can withstand harsh handling conditions without breaking down easily.

Lightweight EPP Molded Foam Packaging: A Solution from Holland, Ohio

Lightweight EPP Molded Foam Packaging, originating from Holland, Ohio, is a revolutionary solution in the realm of packaging and protection. This innovative product is crafted from expanded polypropylene (EPP), a versatile and sustainable material known for its exceptional strength-to-weight ratio. In terms of benefits, EPP foam offers unparalleled shock absorption, making it an ideal choice for delicate items that require careful handling during transit.

The lightweight nature of this molded foam packaging is not just environmentally friendly but also significantly reduces shipping costs by minimizing overall weight and bulk. This makes it a game-changer for industries seeking efficient, cost-effective, and reliable protection for their products. Moreover, its customizable design ensures perfect fitting around various shapes and sizes, providing the ultimate solution for unique packaging challenges.

How to Choose the Right Foam Insert for Your Product Packaging

When selecting a custom-molded foam insert for your product packaging, consider the unique needs of your item and brand. Lightweight Epp molded foam packaging from Holland, Ohio offers numerous benefits for various industries. Expanded polypropylene (EPP) is known for its superior shock absorption properties, making it ideal for fragile or delicate items. This versatile material can be molded into intricate shapes to perfectly fit and secure products within the packaging.

The right foam insert should provide ample protection while also considering cost-effectiveness and environmental impact. EPP foam solutions are often recycled and biodegradable, aligning with eco-conscious consumer preferences. Additionally, its lightweight nature reduces shipping weights, potentially lowering freight costs. By carefully evaluating these factors, you can choose an Epp molded foam packaging solution that enhances the overall unboxing experience for your customers while staying true to your brand’s values.