Lightweight steel packaging is transforming industries with its unique blend of strength, sustainability, and cost-effectiveness. Using innovative manufacturing techniques, custom steel packaging reduces material waste while maintaining structural integrity, leading to lower carbon footprints and freight charges. Its recyclability, durability, and versatility make it an attractive option for brands seeking to enhance product presentations while minimizing environmental impact. Customizable designs tailored to specific products offer significant sustainability advantages, such as efficient material use and reduced waste. Industries like food manufacturing and automotive production are widely adopting sustainable steel packaging solutions to reduce their environmental footprint. Advanced production methods and digital design tools further support a circular economy, making custom steel packaging a popular choice in competitive markets. Despite initial costs, the long-term environmental benefits and potential savings make it a promising avenue toward industry sustainability.

Lightweight steel packaging is revolutionizing the way we think about containerization, offering a compelling blend of strength, durability, and sustainability. This article delves into the multifaceted world of lightweight steel packaging, exploring its benefits for environmental stewardship through sustainable steel packaging solutions. We analyze the role of customization in creating tailored steel packaging, highlighting its applications across diverse industries. Additionally, we discuss production innovations and future prospects, addressing challenges to chart a path forward for this game-changing material.

- Understanding Lightweight Steel Packaging: A Overview

- Benefits of Steel Packaging Solutions for Sustainability

- The Role of Customization in Steel Packaging

- Applications and Industries Adopting Sustainable Steel Packaging

- Production Processes and Innovations in Steel Packaging

- Challenges and Future Prospects of Lightweight Steel Packaging

Understanding Lightweight Steel Packaging: A Overview

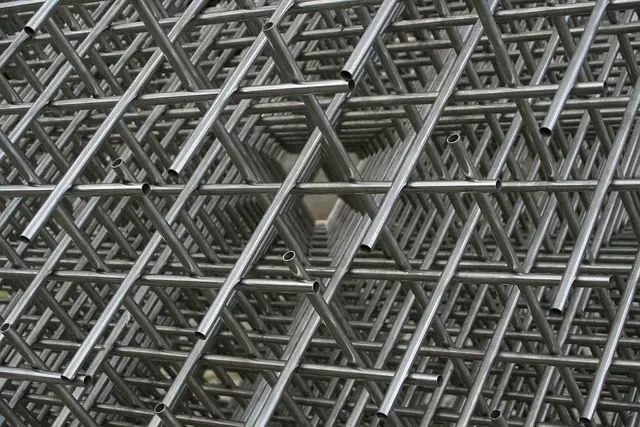

Lightweight steel packaging is revolutionizing the industry with its unique blend of strength and sustainability. In today’s eco-conscious market, consumers and businesses are seeking sustainable steel packaging alternatives that don’t compromise on quality or durability. Steel has long been a trusted material for packaging due to its excellent resistance to corrosion and impact, making it ideal for various applications. However, traditional steel packages can be heavy, leading to increased transportation costs and environmental concerns. This is where lightweight steel packaging solutions step in, offering the same robust protection with significantly reduced weight.

By utilizing innovative manufacturing techniques, custom steel packaging designed for lightness maintains its structural integrity while minimizing material usage. This approach not only benefits the environment by reducing carbon footprints but also offers cost advantages through lower freight charges and more efficient storage. Moreover, lightweight steel packages can enhance brand visibility and product appeal on store shelves, as they often stand out due to their sleek and modern design. As a result, many companies are turning towards these sustainable steel packaging options to meet the changing demands of both consumers and regulators.

Benefits of Steel Packaging Solutions for Sustainability

Steel packaging solutions offer a compelling case for sustainability in the ever-evolving landscape of eco-friendly materials. One of its key advantages lies in its recyclability; steel is an infinitely recyclable material, meaning it can be reused without loss of quality or properties. This circularity significantly reduces waste and minimizes environmental impact compared to many other packaging options. Moreover, custom steel packaging allows for precise design and size tailoring to specific product needs, leading to less material waste during production and transportation.

The durability of sustainable steel packaging is another significant plus. It provides robust protection for goods, reducing the need for excessive packaging to compensate for fragility. This longevity translates into cost savings for businesses and a lower environmental footprint, as fewer resources are consumed in replacing damaged or discarded packaging. With its versatility, steel packaging can be transformed into various innovative formats, catering to different product types and industries while maintaining its commitment to sustainability.

The Role of Customization in Steel Packaging

In today’s competitive market, customization plays a pivotal role in setting steel packaging apart as a leading solution for brands seeking to enhance their product presentations. Custom steel packaging allows manufacturers and businesses to create unique designs, sizes, and shapes tailored to specific products, ensuring an optimal fit and visual appeal. This level of customization not only adds value to the overall brand experience but also offers numerous advantages in terms of sustainability.

By embracing custom steel packaging, companies can efficiently utilize materials, reducing waste and contributing to a more sustainable approach to steel packaging solutions. The versatility of steel allows for creative designs that can include intricate patterns, vibrant colors, or innovative structural elements, all while maintaining the material’s renowned durability and recyclability. This balance between aesthetics and sustainability makes custom steel packaging an attractive option for businesses aiming to leave a positive environmental footprint.

Applications and Industries Adopting Sustainable Steel Packaging

Lightweight steel packaging is transforming industries across various sectors, offering a compelling blend of durability and sustainability. Its applications are diverse, ranging from food and beverage cans to automotive components and even consumer electronics. This versatility makes steel packaging an attractive option for businesses seeking environmentally friendly alternatives without compromising quality or performance.

The adoption of sustainable steel packaging is particularly prominent in industries committed to reducing their environmental footprint. Food and beverage manufacturers, for instance, are embracing steel for its ability to extend product shelf life and preserve freshness. Custom steel packaging allows brands to design unique shapes and sizes tailored to specific products, enhancing market appeal while ensuring resource efficiency. Similarly, the automotive industry is leveraging lightweight steel packaging to reduce vehicle weight, leading to better fuel economy and lower carbon emissions.

Production Processes and Innovations in Steel Packaging

The production processes for lightweight steel packaging have evolved significantly, driving innovations in both material composition and manufacturing techniques. Today, steel packaging manufacturers employ advanced technologies to create custom steel packaging solutions that are not only durable but also environmentally friendly. One notable trend is the adoption of thinner gauge steels while maintaining structural integrity, thereby reducing weight without compromising quality. This approach aligns with the growing demand for sustainable steel packaging among consumers and businesses alike.

Additionally, industry players are leveraging digital design tools to offer unparalleled customization options, ensuring that every piece of steel packaging meets specific client needs. These innovations not only cater to the diverse requirements of various industries but also contribute to a more circular economy by extending the lifespan of materials and reducing waste. As such, custom steel packaging is fast becoming a preferred choice for those seeking robust, eco-conscious, and tailored solutions in an increasingly competitive market.

Challenges and Future Prospects of Lightweight Steel Packaging

Lightweight steel packaging offers a promising path towards sustainability in the industry, but it’s not without its challenges. One of the primary hurdles is the initial cost; implementing lightweight solutions can be more expensive than traditional methods. This is especially true for smaller businesses that might struggle to invest in custom steel packaging designs optimized for reduced weight and material usage. However, long-term environmental benefits and potential cost savings through recycling and waste reduction make these challenges surmountable.

Looking ahead, the future of lightweight steel packaging seems bright. Advancements in manufacturing technology enable more efficient production of custom steel packaging solutions, tailored to specific product needs. Increased awareness about sustainable steel packaging and government incentives for eco-friendly practices will further drive its adoption. As consumer demands for environmentally conscious products grow, so too will the market’s response, paving the way for a greener and more sustainable future in packaging.