Electrical Hazard Analysis is a thorough process aimed at ensuring arc flash safety and adhering to industry standards (like NFPA). It involves assessing voltage, current, energy levels, and work practices to identify risks associated with arc flashes. By examining equipment, tasks, and protocols, experts can pinpoint compliance gaps, enabling targeted risk mitigation strategies and full arc flash compliance, thus safeguarding workers from electrical hazards through the arc flash study process.

An Arc Flash compliance audit is crucial for identifying and mitigating electrical hazards in the workplace. This comprehensive guide delves into the essential components of an arc flash study process, from initial risk assessment to implementing robust arc flash safety standards. By understanding these steps, you can ensure a safer environment for your employees and comply with relevant regulations. We’ll explore how thorough electrical hazard analysis reveals compliance gaps, guiding you towards effective solutions.

- Understanding Arc Flash Study Process: A Step-by-Step Guide

- Electrical Hazard Analysis: Identifying Risks and Compliance Gap

- Arc Flash Safety Standards: Ensuring Workplace Protection Through Implementation

Understanding Arc Flash Study Process: A Step-by-Step Guide

Electrical Hazard Analysis: Identifying Risks and Compliance Gap

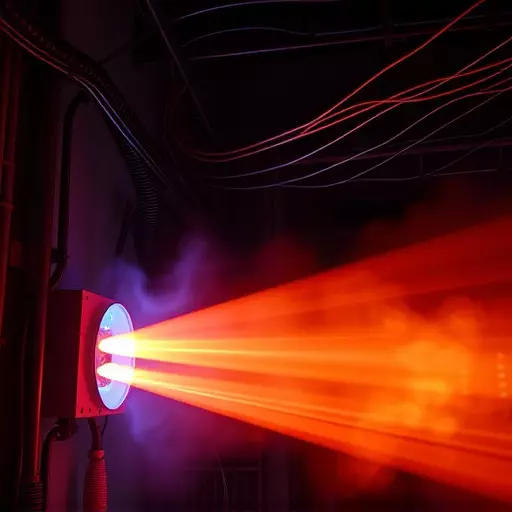

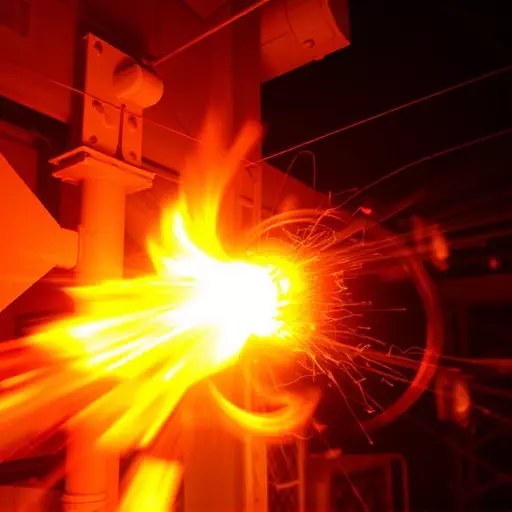

Electrical Hazard Analysis is a critical step in ensuring arc flash safety and compliance with relevant standards. It involves meticulously assessing electrical systems, equipment, and work practices to identify potential risks associated with arc flashes. By conducting a thorough analysis, organizations can uncover hidden dangers and areas where existing controls may be inadequate. This process includes evaluating factors such as voltage, current, and energy levels, as well as the proximity of personnel and their protective gear to hazardous electrical sources.

During this study, experts examine work tasks, equipment ratings, and existing safety protocols to pinpoint compliance gaps. They identify scenarios where arc flash safety standards may be overlooked or misapplied, ensuring a comprehensive understanding of risks specific to each facility. This analysis is an essential foundation for implementing effective risk mitigation strategies and making necessary upgrades to achieve full arc flash compliance.

Arc Flash Safety Standards: Ensuring Workplace Protection Through Implementation

Arc Flash Safety Standards play a pivotal role in safeguarding workers from electrical hazards and are an integral part of any comprehensive workplace safety program. These standards, often derived from organizations like the National Fire Protection Association (NFPA), provide guidelines for conducting thorough Electrical Hazard Analysis (EHA). An arc flash study process involves evaluating potential risks associated with electrical systems to determine appropriate protective measures.

Implementing these safety standards requires a systematic approach, beginning with identifying live parts exposed to the environment and assessing their energy levels. By understanding the characteristics of electrical arcs and their potential consequences, employers can ensure that personal protective equipment (PPE) is suitable and employees are trained effectively. This proactive measure not only mitigates risks but also aligns with regulatory requirements for arc flash safety standards.