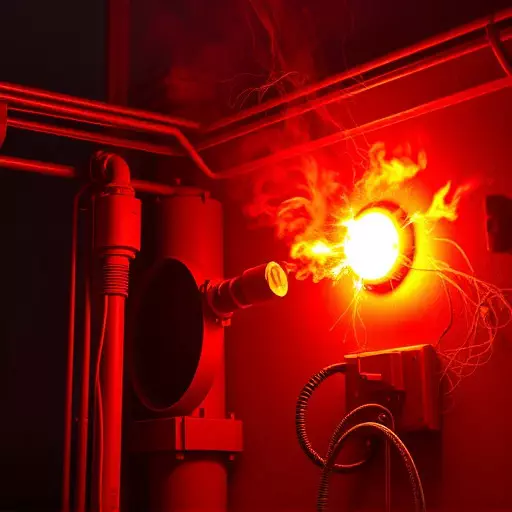

An in-depth Arc Flash Hazard Analysis (AFHA) is crucial for identifying and mitigating risks associated with electrical systems. By assessing potential hazards, organizations can implement effective strategies to reduce the risk of arc flashes, ensuring electrical safety compliance. This process involves evaluating equipment, operational procedures, and personal protective equipment (PPE), ultimately leading to a safer work environment and minimizing the impact of arc flash incidents.

In the realm of electrical safety, understanding and mitigating arc flash hazards is paramount for ensuring worker well-being and preventing catastrophic incidents. This article delves into arc flash hazard assessment tools designed to facilitate comprehensive analysis and risk reduction. By exploring these tools, professionals can identify potential sources of arc flashes, implement effective protective measures, and achieve electrical safety compliance, ultimately fostering a safer work environment.

Arc flash hazard analysis is an essential component of maintaining electrical safety compliance in industrial settings. These detailed assessments help identify potential risks associated with high-energy electrical arcs, which can cause severe injuries or even fatalities. By utilizing specialized tools and methodologies, facility managers and safety professionals can comprehensively evaluate equipment, work practices, and environmental conditions to determine the likelihood and severity of arc flash incidents. This proactive approach enables targeted strategies for arc flash risk reduction, ensuring a safer working environment.

Effective arc flash hazard assessment tools consider various factors, such as equipment rating, clearance distances, and personal protective equipment (PPE) requirements. They provide step-by-step guidelines to analyze and categorize arcs based on their energy levels, allowing for appropriate control measures. Regular assessments and updates are crucial to adapt to changing work conditions, new equipment installations, or modifications in operational procedures, thereby maintaining a robust electrical safety program.