Arc flashes pose significant risks in industrial settings, requiring proactive mitigation through an arc flash study process. This involves a detailed Electrical Hazard Analysis (EHA) to identify arcing potential and assess energy release, adhering to NFPA 70E guidelines. Data from the EHA guides safety standards for equipment design, maintenance, and employee training. By integrating this analysis, industries can implement robust arc flash safety protocols, minimizing force, heat, and fire hazards associated with arcing events. Regular updates ensure dynamic risk management and worker safety.

In the realm of industrial safety, understanding and mitigating arc flash risks are paramount. This comprehensive guide delves into best practices for arc flash prevention, focusing on crucial aspects like recognizing potential hazards, conducting an in-depth arc flash study process, and adhering to established electrical hazard analysis methods. By implementing these strategies, organizations can effectively navigate and minimize the impact of arc flashes, ensuring a safer working environment in compliance with arc flash safety standards.

- Understanding Arc Flash Risks and Their Impact

- The Arc Flash Study Process: A Comprehensive Guide

- Implementing Electrical Hazard Analysis for Effective Risk Mitigation

- Adhering to Arc Flash Safety Standards: Best Practices

Understanding Arc Flash Risks and Their Impact

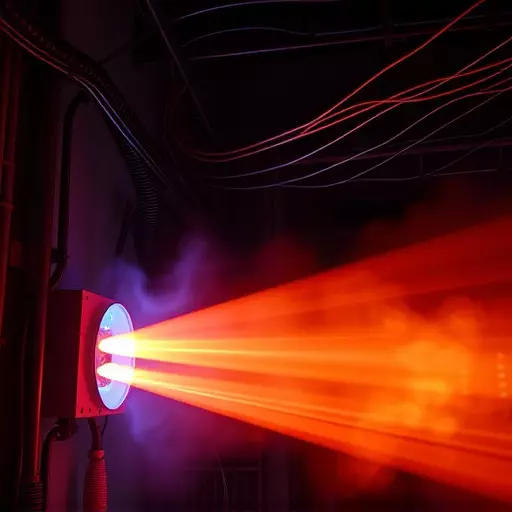

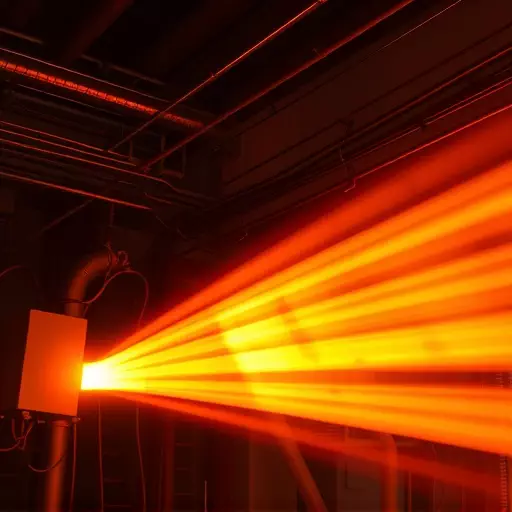

Arc flashes are a significant electrical hazard in industrial settings, capable of causing severe injuries and damage. Understanding arc flash risks is crucial to implementing effective prevention strategies. The arc flash study process involves a thorough analysis of electrical systems to identify potential sources of arcing, assess their energy release potential, and evaluate the vulnerability of nearby personnel and equipment. This data-driven approach, informed by an electrical hazard analysis, forms the backbone of robust arc flash safety standards.

By understanding the impact of arc flashes—including the force they exert, the heat they generate, and the subsequent fire hazards—facilities can implement targeted measures to mitigate risks. Arc flash safety standards, such as those established by organizations like NFPA 70E, provide guidelines for equipment design, installation, maintenance, and employee training, ensuring a safer working environment for electrical personnel.

The Arc Flash Study Process: A Comprehensive Guide

The Arc Flash Study Process serves as a comprehensive guide for identifying and mitigating electrical hazards, aligning with arc flash safety standards. It begins with a thorough Electrical Hazard Analysis (EHA), where professionals meticulously assess every electrical system within a facility. This involves scrutinizing equipment, wiring, and components to pinpoint potential arc flash points. Data collection includes recording voltage, current, power, and frequency, along with equipment ratings and clearances.

Once the EHA is complete, the information is used to perform detailed calculations for each identified hazard. These calculations determine arcing events’ characteristics, such as energy release and duration. Based on these results, a risk assessment is conducted to evaluate the likelihood and severity of potential arc flash incidents. This data guides the implementation of safety measures, like appropriate personal protective equipment (PPE), system upgrades, and work practices designed to prevent or minimize arc flash risks.

Implementing Electrical Hazard Analysis for Effective Risk Mitigation

Implementing Electrical Hazard Analysis is a comprehensive and systematic approach to identifying and mitigating risks associated with arc flashes in industrial settings. This process involves a detailed arc flash study, which evaluates the electrical system’s design, operation, and potential failure modes. By examining equipment ratings, insulation, clearances, and fault conditions, professionals can determine the likelihood and magnitude of an arc flash event.

The results of this analysis guide the development of robust safety strategies, ensuring compliance with arc flash safety standards. It allows for the selection of appropriate personal protective equipment (PPE), the implementation of control measures like overcurrent protection and grounding systems, and the design of safe work practices to minimize exposure during maintenance or repair tasks. Regular updates to the analysis are crucial as electrical systems evolve, ensuring ongoing risk management and enhanced worker safety.

Adhering to Arc Flash Safety Standards: Best Practices

Adhering to Arc Flash Safety Standards is a multifaceted approach that begins with a comprehensive arc flash study process. This involves a thorough evaluation of electrical systems and equipment to identify potential hazards. An arc flash is a powerful, often devastating electrical event that can cause severe injuries or even fatalities. By conducting a detailed analysis, which includes identifying high-risk areas, determining appropriate protective measures, and implementing proper labeling and training protocols, organizations can significantly mitigate these risks.

Best practices dictate regular updates to this analysis, as electrical systems evolve over time. This dynamic nature ensures that safety standards remain relevant and effective. Incorporating an electrical hazard analysis into the study process allows for a systematic approach to identifying and addressing vulnerabilities. It’s not just about compliance; it’s about fostering a culture of safety where every employee understands their role in preventing arc flash incidents, leading to safer work environments and more robust operational continuity.