TL;DR:

Chemical exposure risk management hinges on robust industrial hygiene protocols, encompassing regular inspections, air quality testing, and biological monitoring. Core to this process is hazardous material identification, utilizing tools like safety data sheets (SDS) and spectral analysis. Once identified, materials are categorized based on toxicity, reactivity, and exposure potential to develop targeted risk mitigation strategies. Training employees on chemical safety practices, including hazardous material identification and proper handling, storage, and disposal, is vital for fostering a culture of safety and ensuring compliance with occupational health standards, ultimately enhancing operational efficiency.

In today’s industrial landscape, effective chemical exposure control plans (ECCPs) are paramount for worker safety. This comprehensive guide delves into essential aspects of managing chemical risks, including hazardous material identification and robust industrial hygiene protocols. We explore best practices for implementing control measures, monitoring employee safety, training staff, and regularly updating ECCPs to ensure compliance and mitigate potential dangers. By embracing these strategies, organizations can create a safer, healthier work environment.

- Understanding Chemical Exposure Risk Management

- Identifying Hazardous Materials in the Workplace

- Developing Comprehensive Industrial Hygiene Protocols

- Implementing Effective Control Measures for Chemical Exposure

- Monitoring and Evaluating Employee Safety

- Training Employees on Chemical Safety Practices

- Regular Review and Updates to Exposure Control Plans

Understanding Chemical Exposure Risk Management

Identifying Hazardous Materials in the Workplace

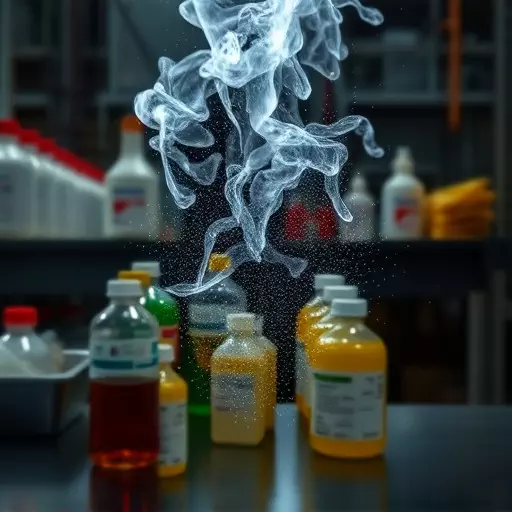

Identifying hazardous materials in the workplace is a critical step in managing chemical exposure risk and implementing effective industrial hygiene protocols. This process involves thoroughly evaluating all substances present, from raw materials to finished products, to determine potential health hazards. By conducting comprehensive assessments, organizations can create a detailed inventory of hazardous materials, enabling them to take proactive measures for control and mitigation.

Effective hazard identification requires utilizing various resources and methods. This includes reviewing safety data sheets (SDS), which provide essential information about chemical properties, exposure limits, and necessary precautions. Additionally, employing advanced technologies like spectral analysis or conducting material tests can aid in positive hazardous material identification. Once identified, these substances should be categorized based on their toxicity, reactivity, and potential for exposure, allowing for targeted risk management strategies to be developed and implemented.

Developing Comprehensive Industrial Hygiene Protocols

Implementing Effective Control Measures for Chemical Exposure

Monitoring and Evaluating Employee Safety

Effective chemical exposure control begins with thorough monitoring and evaluating employee safety. Industrial hygiene protocols are essential tools in identifying and mitigating hazardous material risks. Regular inspections, air quality testing, and biological monitoring help organizations understand the extent of chemical exposure among their workforce. By implementing these industrial hygiene protocols, companies can identify hidden dangers and ensure compliance with occupational health standards.

Additionally, proper training is vital to empower employees to recognize potential hazards and take proactive measures. This includes education on hazardous material identification, safe handling procedures, and emergency response plans. Continuous monitoring and evaluation foster a culture of safety where everyone understands their role in managing chemical exposure risks, ultimately creating a healthier work environment.

Training Employees on Chemical Safety Practices

Training employees on chemical safety practices is a cornerstone of effective chemical exposure risk management. It ensures that workers are equipped to handle hazardous materials responsibly, minimizing potential risks to their health and the environment. Industrial hygiene protocols should be integrated into regular training sessions to educate employees about proper use, storage, and disposal methods for various chemicals. This includes recognizing potential hazards, understanding safety data sheets (SDS), and using personal protective equipment (PPE) appropriately.

By mastering these skills, employees can actively contribute to a safer work environment. They’ll be able to identify hazardous materials quickly, implement relevant control measures, and respond effectively in case of an emergency. Regular refreshers and specific training for new substances or processes ensure continuous adherence to industrial hygiene standards and promote a culture of chemical safety across the organization.

Regular Review and Updates to Exposure Control Plans