The Double Check Valve Assembly (DCVA) is a crucial component for securing safe water supply systems in Spring Lake areas prone to pressure fluctuations. It acts as both commercial and residential backflow preventers, monitoring and controlling pressure changes and flow direction to protect drinking water from contamination. Before installation, thoroughly assess your property's water system, including pipe materials, fixture ages, and potential contamination sources, for compliance with local regulations and effective DCVA operation. The installation process involves shutting off the main valve, preparing pipes, attaching the DCVA, and testing its functionality. Regular testing and maintenance, adhering to legal requirements, and addressing common issues are vital for the DCVA's effective operation in both commercial and residential settings.

“Ensure safe water flow with a Double Check Valve Assembly (DCVA) installation in your Spring Lake property. This comprehensive guide explores the crucial role of DCVAs as backflow preventers, vital for commercial and residential properties alike. From understanding the component parts to navigating legal requirements, we demystify the process. Learn about assessment, installation best practices, testing, and troubleshooting tips. Whether you’re in a bustling commercial hub or a peaceful residence, this article equips you with insights on Spring Lake’s backflow preventer installation, highlighting key differences between commercial and residential setups.”

- Understanding Double Check Valve Assembly (DCVA): Its Role as a Backflow Preventer

- Preparing for Installation: Assessing Your Spring Lake Property for DCVA

- Commercial vs. Residential Backflow Preventer Installation: Key Differences

- Step-by-Step Guide to Installing a DCVA in Your Home or Business

- Ensuring Proper Operation: Testing and Maintenance of the Backflow Preventer

- Legal Requirements and Regulations for Backflow Preventer Installation in Spring Lake

- Common Issues and Troubleshooting Tips for Efficient DCVA Operation

Understanding Double Check Valve Assembly (DCVA): Its Role as a Backflow Preventer

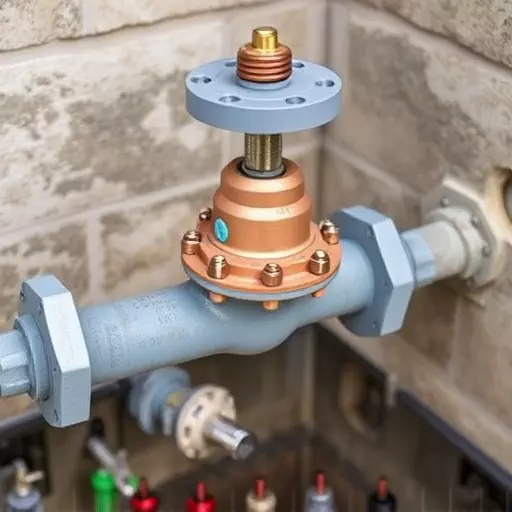

The Double Check Valve Assembly (DCVA) is a crucial component in ensuring safe water supply systems, especially when it comes to backflow prevention. As a critical device in both commercial and residential settings, its primary role is to safeguard drinking water from potential contamination. Backflow preventers are essential for Spring Lake areas where water pressure fluctuations can create conditions allowing contaminated water to flow back into the main supply line.

DCVAs work by providing two independent checks to prevent backflow. This means they ensure that any change in pressure or flow direction is safely monitored and controlled, preventing harmful substances from flowing backward into clean water sources. Whether installed in a commercial building’s complex plumbing system or as part of a residential property’s water supply, these devices are game-changers in maintaining water quality and safety standards.

Preparing for Installation: Assessing Your Spring Lake Property for DCVA

Before diving into the installation process of a Double Check Valve Assembly (DCVA), it’s crucial to assess your Spring Lake property and understand its water system. This step is vital for both commercial backflow preventer installation and residential backflow preventer installation, ensuring the DCVA operates effectively and complies with local regulations. Begin by inspecting your property’s water supply lines, identifying potential hazards, and checking for any existing backflow prevention devices.

Consider factors like pipe materials, ages of fixtures, and the proximity to known contamination sources. These evaluations will help determine if any pre-installation modifications are necessary. Understanding your property’s unique characteristics enables you to navigate the backflow preventer installation process smoothly and guarantees the safety and integrity of your water supply.

Commercial vs. Residential Backflow Preventer Installation: Key Differences

When it comes to installing a backflow preventer in Spring Lake, whether for commercial or residential purposes, there are notable differences to consider. Commercial backflow preventer installations often involve more complex systems due to higher water pressure and flow rates typical in commercial settings. This complexity necessitates specialized knowledge and equipment to ensure the valve assembly functions correctly and meets safety standards.

In contrast, residential backflow preventer installation focuses on individual homes, where lower water pressures and flows demand a different approach. The process is generally simpler but no less crucial for protecting drinking water supplies from contamination. Residential installations require precise sizing and configuration tailored to each home’s unique plumbing setup.

Step-by-Step Guide to Installing a DCVA in Your Home or Business

Installing a Double Check Valve Assembly (DCVA) is an essential step in ensuring the safety of your water supply, whether it’s for residential or commercial purposes. Here’s a straightforward guide to help you navigate the process. Start by turning off the main water supply valve located near your meter. This prevents any unintended water flow during installation. Next, locate the pipes connected to the fixture or appliance where the DCVA will be installed. Prepare the area by shutting off the relevant valves and draining any excess water from the affected lines.

With the pipes exposed, attach the DCVA by connecting the inlet and outlet ports to the respective pipes using suitable fittings. Ensure all connections are secure and leak-free. The valve should be installed with its flow direction aligned correctly to allow water to pass through in one direction while preventing backflow. Once the physical installation is complete, test the DCVA’s functionality by activating the handle to ensure it operates smoothly and effectively stops water flow in the reverse direction. This step is crucial for confirming proper backflow preventer installation Spring Lake and ensuring your water system’s integrity.

Ensuring Proper Operation: Testing and Maintenance of the Backflow Preventer

After completing the DCVA installation in Spring Lake, ensuring proper operation is paramount to maintain water quality and safety. One critical component of this process involves rigorous testing and ongoing maintenance of the backflow preventer. This includes conducting regular checks to verify its integrity and functionality, especially in commercial and residential settings where backflow prevention is mandatory.

Testing should encompass a comprehensive evaluation of the backflow preventer’s ability to stop backflow, ensuring it operates as designed. Regular maintenance routines, such as inspecting for any signs of damage or corrosion and replacing worn-out parts, are essential. Commercial and residential property owners alike must stay proactive in these tasks to safeguard their water systems from potential contaminants and ensure compliance with local regulations, enhancing overall water safety in Spring Lake.

Legal Requirements and Regulations for Backflow Preventer Installation in Spring Lake

In Spring Lake, the installation of a backflow preventer is subject to specific legal requirements and regulations designed to ensure water safety. Both commercial and residential properties must adhere to these standards, which govern the type, placement, and maintenance of backflow devices. For instance, the local health department oversees the installation process, ensuring that all backflow preventers meet the necessary specifications and are correctly fitted to stop any potential contamination of the public water supply.

When undertaking a backflow preventer installation in Spring Lake, it’s crucial to consult these regulations. This includes understanding the requirements for testing, certification, and record-keeping. Proper documentation and compliance are vital to avoid legal issues and ensure the safety of the community’s water system. Whether for commercial or residential use, adhering to these guidelines is essential for a seamless installation process.

Common Issues and Troubleshooting Tips for Efficient DCVA Operation

The successful operation of a Double Check Valve Assembly (DCVA) relies on meticulous installation and ongoing maintenance. Common issues often arise from improper assembly, inadequate backflow prevention, or neglect of regular checks. During or after backflow preventer installation Spring Lake or in any commercial/residential setting, it’s crucial to address potential problems proactively. One frequent issue is a faulty spring within the DCVA, which can lead to inadequate sealing or failure to engage the check valves properly. Regular visual inspections and replacement of worn-out parts are essential to prevent such complications.

Another common challenge involves improper piping or connections, which may result in water pressure imbalances and cause the DCVA to malfunction. Ensuring all components are securely fastened and aligned during commercial backflow preventer installation or residential backflow preventer installation is vital. Additionally, keeping records of maintenance activities and promptly addressing any unusual noises, leaks, or changes in water pressure will contribute to efficient DCVA operation and help avoid more serious backflow issues.