Arc Flash Hazard Analysis (EFHA) is a critical process for electrical safety compliance, focusing on identifying and mitigating risks from arc flash events. By evaluating voltage, current, protective equipment, and energy release (cal/cs), organizations can implement targeted strategies to reduce arc flash risk. This includes system design modifications, maintenance protocols, proper labeling, employee training, and providing appropriate personal protective equipment (PPE). Regular electrical safety assessments, adherence to standards like NFPA 70E, and strategic action plans ensure ongoing compliance and mitigate potential hazards, fostering a safe work environment.

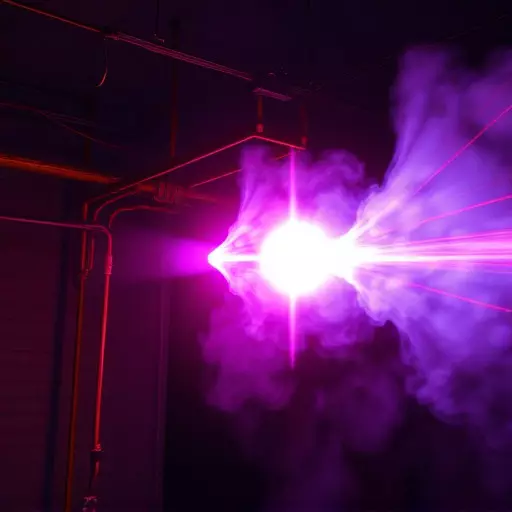

Electrical hazards pose significant risks in industrial settings, with arc flashes being a particularly dangerous phenomenon. This comprehensive guide delves into the intricacies of Arc Flash Hazard Analysis, a critical process for ensuring electrical safety compliance. We explore key factors in identifying risks, effective strategies to mitigate arc flash risk, and best practices for regular assessments. By understanding these aspects, organizations can enhance workplace safety through proactive measures and continuous improvement post-assessment.

- Understanding Arc Flash Hazard Analysis: A Comprehensive Guide

- Identifying Risks: Key Factors in Electrical Safety Compliance

- Implementing Effective Strategies for Arc Flash Risk Reduction

- Best Practices for Conducting Regular Electrical Safety Assessments

- Enhancing Workplace Safety: Post-Assessment Action Plan and Continuous Improvement

Understanding Arc Flash Hazard Analysis: A Comprehensive Guide

Arc Flash Hazard Analysis is a critical component of electrical safety compliance, offering a comprehensive guide to identifying and mitigating risks associated with arc flash events. This process involves a thorough evaluation of an electrical system’s potential for creating an arc flash, which can result in severe injuries or even fatalities. By systematically examining factors such as voltage, current, and protective equipment, organizations can implement targeted strategies to reduce arc flash risk.

A key aspect of this analysis is understanding the energy released during an arc flash incident. This energy, measured in calories per centi-second (cal/cs), determines the severity of potential injuries. The higher the cal/cs value, the greater the hazard. Armed with this knowledge, safety professionals can make informed decisions about personal protective equipment (PPE) requirements, system design modifications, and maintenance protocols to ensure electrical safety compliance and protect workers from arc flash hazards.

Identifying Risks: Key Factors in Electrical Safety Compliance

Identifying risks is a fundamental step in ensuring electrical safety compliance. A thorough assessment begins with understanding the key factors that contribute to potential hazards. One significant concern is the arc flash hazard analysis, which involves evaluating the likelihood and consequences of an arc flash event. This includes examining equipment design, voltage levels, and protective devices to determine the level of risk associated with each piece of electrical infrastructure. By conducting such analyses, organizations can implement targeted strategies for arc flash risk reduction.

Various factors influence electrical safety compliance. Proper labeling and signage, for instance, play a crucial role in alerting workers to potential dangers. Additionally, regular maintenance and inspection are essential to identify aging or faulty equipment that may pose increased risks. Training employees on safe work practices and providing them with personal protective equipment (PPE) tailored to their tasks further enhances electrical safety measures. Integrating these elements into a comprehensive risk management plan enables businesses to stay compliant and foster a culture of electrical safety awareness.

Implementing Effective Strategies for Arc Flash Risk Reduction

Implementing effective strategies for arc flash risk reduction is crucial for ensuring electrical safety compliance and minimizing potential hazards in industrial settings. An arc flash hazard analysis (EFHA) serves as a critical first step, identifying vulnerable areas and equipment prone to arcing events. By systematically evaluating factors like system design, maintenance practices, and personnel training, organizations can pinpoint specific risks associated with their electrical systems.

Once identified, targeted interventions can be implemented to mitigate these risks. This includes upgrading outdated equipment, installing advanced protective devices such as surge protection devices (SPDs), and enforcing rigorous maintenance routines to prevent insulator degradation. Additionally, proper personal protective equipment (PPE) and training programs should be provided to employees, empowering them with the knowledge and tools necessary to work safely around high-risk electrical systems.

Best Practices for Conducting Regular Electrical Safety Assessments

Regular electrical safety assessments are non-negotiable for any facility or business dealing with electrical systems and equipment. These evaluations go beyond simple visual inspections, delving into a comprehensive analysis of potential risks and hazards. A key component is conducting an arc flash hazard analysis, which identifies and quantifies the risks associated with electric arcs. This involves assessing factors like voltage, current, and the proximity of personnel to live parts during fault conditions. By understanding these variables, facilities can implement targeted strategies for arc flash risk reduction.

Best practices dictate that assessments should be conducted by qualified professionals who adhere to industry standards such as NFPA 70E. Regular inspections ensure ongoing electrical safety compliance, allowing for prompt identification and mitigation of potential issues. Additionally, implementing a robust maintenance program, keeping records of findings, and training employees on recognized safety protocols are essential steps in managing and minimizing electrical hazards.

Enhancing Workplace Safety: Post-Assessment Action Plan and Continuous Improvement

After conducting a thorough electrical hazard assessment, the next step is to develop a comprehensive action plan to mitigate risks and enhance workplace safety. This involves prioritizing identified hazards based on their potential severity and likelihood of occurrence, and implementing targeted strategies to reduce or eliminate them. A structured approach can include immediate corrective actions, short-term mitigations, and long-term solutions tailored to the facility’s unique electrical landscape.

Continuous improvement is integral to maintaining a safe working environment. Regular audits, employee training on new protocols, and staying updated with industry standards and best practices ensure that safety measures remain effective. By fostering a culture of awareness and proactivity, organizations can significantly reduce the risk of arc flash incidents, promote electrical safety compliance, and foster an environment where everyone returns home safely at the end of their shift.