OSHA workplace safety inspections rely on thorough hazard assessment protocols to identify and mitigate risks, ensuring compliance with Safety Data Sheet (SDS) regulations. These inspections involve meticulous reviews of physical conditions, equipment, chemical exposures, and employee training records. By adhering to strict SDS management practices, companies can empower employees to make informed decisions about hazardous substances, significantly reducing workplace accidents, injuries, and illnesses. Effective hazard assessment protocols begin with identifying all potential hazards through site inspections, record reviews, and employee consultations, then evaluating their severity and likelihood. Proper documentation and communication throughout this process are crucial for aligning with OSHA standards and fostering a proactive culture of safety.

Hazard assessment protocols are a cornerstone of workplace safety, enabling organizations to proactively identify and mitigate risks. This article delves into the essential components of OSHA workplace safety inspections, highlighting their role as a foundation for comprehensive hazard assessment. We explore how these protocols enhance employee safety, focusing on critical aspects such as Safety Data Sheet (SDS) compliance. Additionally, we provide practical steps, common mistakes to avoid, and best practices for documenting and communicating findings, ensuring a thorough understanding of effective hazard assessment methodologies.

- Understanding OSHA Workplace Safety Inspections: A Foundation for Hazard Assessment

- The Role of Hazard Assessment Protocols in Ensuring Employee Safety

- Unlocking the Importance of Safety Data Sheet (SDS) Compliance

- Comprehensive Steps for Conducting a Successful Hazard Assessment

- Common Mistakes to Avoid During Hazard Identification and Risk Evaluation

- Best Practices for Documenting and Communicating Hazard Assessment Findings

Understanding OSHA Workplace Safety Inspections: A Foundation for Hazard Assessment

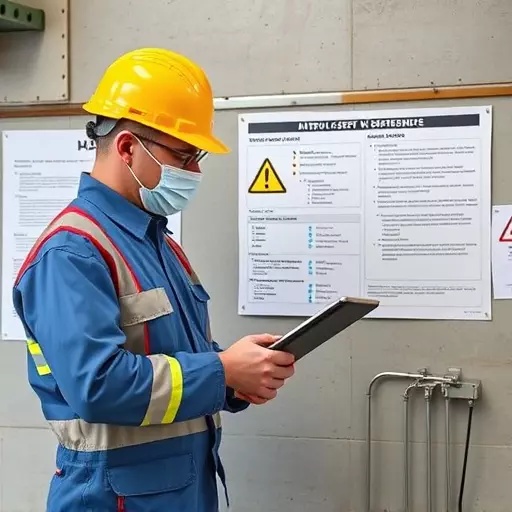

OSHA (Occupational Safety and Health Administration) workplace safety inspections are a cornerstone in establishing robust hazard assessment protocols. These inspections provide a systematic framework for identifying potential risks within a work environment, ensuring compliance with safety regulations. During an OSHA inspection, trained professionals meticulously examine various aspects of the workplace, including physical conditions, equipment, machinery, chemical exposure, and employee training records.

By adhering to these rigorous standards, companies can better understand their obligations regarding safety data sheet (SDS) management and hazard communication. The insights gained from such inspections enable businesses to implement effective risk mitigation strategies, fostering a safer working atmosphere. Regular assessments based on OSHA guidelines serve as a proactive measure, ultimately reducing the likelihood of workplace accidents and injuries.

The Role of Hazard Assessment Protocols in Ensuring Employee Safety

Hazard assessment protocols play a pivotal role in OSHA workplace safety inspections and ensuring comprehensive employee safety. These structured processes are designed to identify potential risks within a work environment, enabling employers to take proactive measures for mitigation. By adhering to rigorous hazard assessment protocols, organizations can maintain a safe and healthy workplace, thereby reducing the likelihood of accidents, injuries, and illnesses.

One of the key aspects of effective hazard assessment is the systematic review and analysis of safety data sheets (SDSs). SDS compliance ensures that employees are equipped with essential information about hazardous substances, their proper handling, and associated safety precautions. This knowledge empowers workers to make informed decisions, significantly contributing to a culture of safety and responsibility in the workplace.

Unlocking the Importance of Safety Data Sheet (SDS) Compliance

In the realm of OSHA workplace safety inspections, adhering to hazard assessment protocols is paramount. One critical aspect often overlooked but immensely significant is Safety Data Sheet (SDS) compliance. SDS provide detailed information about chemical compounds, including their hazards, handling procedures, and first-aid measures. Ensuring that these sheets are up-to-date, easily accessible, and understood by all employees can significantly enhance workplace safety.

During inspections, compliance with SDS requirements serves as a strong indicator of an organization’s commitment to workplace safety. Proper SDS management enables workers to make informed decisions when encountering hazardous materials, thus reducing the risk of accidents or exposure. It’s not just about ticking boxes; it’s about fostering a culture where safety is a shared responsibility, guided by comprehensive and accessible hazard assessment tools like the Safety Data Sheet.

Comprehensive Steps for Conducting a Successful Hazard Assessment

Conducting a thorough hazard assessment is a critical step in ensuring OSHA workplace safety inspections and maintaining compliance with safety data sheet (SDS) requirements. The process involves several comprehensive steps to identify, evaluate, and mitigate potential risks within any work environment.

First, identify all possible hazards present in the workplace, including physical, chemical, biological, and ergonomic factors. This step requires a detailed inspection of the site, reviewing relevant records, and consulting with employees who can provide valuable insights. Once identified, each hazard should be evaluated based on its potential severity and likelihood of occurrence. This evaluation considers exposure scenarios, employee vulnerability, and existing control measures to determine the level of risk. Effective communication is vital; ensuring that all personnel understand the assessment process and any associated risks empowers them to actively participate in maintaining a safe workplace.

Common Mistakes to Avoid During Hazard Identification and Risk Evaluation

During hazard identification and risk evaluation, many organizations inadvertently make common mistakes that can hinder effective OSHA workplace safety inspections and lead to non-compliance with safety data sheet (SDS) regulations. One of the most frequent errors is overlooking obvious hazards due to a lack of thoroughness or experience. Every workplace has potential risks, and neglecting to identify even the most apparent dangers can have severe consequences during an inspection. For instance, forgetting to assess chemical exposure or inadequate ventilation in confined spaces could result in serious health risks for employees.

Another mistake is failing to consider cumulative or long-term hazards. While immediate dangers are easy to spot, chronic issues that develop over time may go unnoticed. These can include repetitive strain injuries from incorrect workstation setup, noise exposure leading to hearing loss, or even stress-related illnesses. To ensure comprehensive hazard assessment protocols, organizations must adopt a holistic approach, examining both immediate and potential long-term risks. This meticulous process will not only enhance workplace safety but also facilitate better SDS compliance.

Best Practices for Documenting and Communicating Hazard Assessment Findings

Effective communication and clear documentation are vital components of successful hazard assessment protocols. When conducting OSHA workplace safety inspections, it’s crucial to meticulously record all findings in a structured manner. This includes detailing identified hazards, their potential impact, and recommended mitigation strategies. A well-organized report facilitates better understanding and promotes proactive measures to enhance workplace safety.

To ensure compliance with safety data sheet (SDS) requirements, hazard assessment documentation should align with industry standards and regulations. Clearly defining and categorizing risks allows for targeted interventions. Effective communication of these findings to all relevant stakeholders—from management to employees—is key to fostering a culture of safety awareness. This inclusive approach empowers everyone to take responsibility for identifying and addressing potential hazards promptly.