Lockout/Tagout (L/T) is a critical safety procedure mandated by OSHA for maintaining high-risk industrial areas during maintenance. Effective L/T practices involve comprehensive training on energy control procedures, including lock and tag application, worker communication, and controlled removal. This ensures safe isolation of hydraulic systems and reduces workplace accidents related to energy hazards. Key aspects include compliance with OSHA standards and regular lockout tagout compliance training, emphasizing knowledge and skills in energy control. By implementing proper L/T protocols, organizations can significantly minimize accidents, injuries, and fatalities, adhering to industry advancements and best practices while fostering a safer work environment.

In today’s industrial landscape, proper lockout/tagout (L/T) procedures are paramount for worker safety. This comprehensive guide explores the critical aspects of hydraulic system lockout training, essential for maintaining compliance with OSHA’s stringent lockout tagout standards. From understanding L/T principles to practical application and common pitfalls, we delve into an effective training program that ensures energy control procedure proficiency. Stay ahead with this crucial resource for safety-conscious organizations.

- Understanding Lockout/Tagout: A Brief Overview

- OSHA's Role and Lockout Tagout Standards

- The Importance of Hydraulic System Lockout Training

- Key Components of an Effective Training Program

- Practical Application and Scenario-Based Learning

- Common Mistakes and How to Avoid Them

- Continuous Improvement and Staying Compliant

Understanding Lockout/Tagout: A Brief Overview

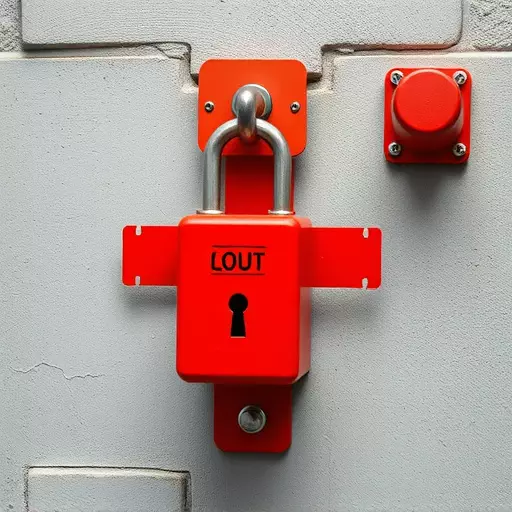

Lockout/Tagout (L/T) is a critical safety procedure designed to prevent accidental activation of energy sources during maintenance or repair activities. This process involves securing machinery or equipment by physically locking out access and tagging out the system, ensuring no one can inadvertently start it up. Compliance with OSHA’s lockout tagout standards is mandatory for all workplaces dealing with potential energy hazards.

Effective L/T practices involve comprehensive training on energy control procedures. This includes understanding when and how to apply locks and tags, proper communication among workers, and safe removal of locks under controlled conditions. Lockout tagout compliance training equips employees with the knowledge and skills to work safely in areas where energy sources could pose a risk, ultimately reducing workplace accidents and injuries.

OSHA's Role and Lockout Tagout Standards

OSHA plays a pivotal role in ensuring workplace safety, particularly when it comes to hydraulic systems and energy control procedures. The organization has established comprehensive lockout/tagout standards to safeguard workers from unexpected equipment activation during maintenance or repair processes. These standards are designed to prevent accidents and injuries by implementing controlled shutdowns and de-energization of machinery.

Lockout tagout compliance training is essential for organizations handling hydraulic systems, as it equips employees with the knowledge and skills to follow safe energy control procedures. By learning these protocols, workers can effectively isolate equipment from its power sources, ensuring a secure environment for maintenance activities. OSHA’s lockout/tagout standards provide a structured framework, guiding businesses on proper techniques and best practices to maintain compliance, thereby fostering a safer work environment.

The Importance of Hydraulic System Lockout Training

In today’s industrial landscape, safety is paramount, especially when dealing with powerful hydraulic systems. Lockout/tagout (L/T) compliance training is an essential component of ensuring worker safety and preventing catastrophic failures. The OSHA lockout tagout standards provide a framework for employers to protect their employees from energy-related hazards during maintenance or repair. By implementing proper energy control procedures through comprehensive L/T training, organizations can significantly reduce the risk of accidents, injuries, and even fatalities.

This training equips workers with the knowledge and skills to safely isolate hydraulic systems, ensuring no residual energy remains before initiating work. It involves understanding various lockout devices, tagout procedures, and the critical importance of proper communication and accountability. With ongoing industry advancements and complex machinery, regular energy control procedures training is crucial to keeping up with best practices and maintaining a safe working environment.

Key Components of an Effective Training Program

An effective hydraulic system lockout training program is integral to ensuring safety in industrial settings, aligning with OSHA’s lockout/tagout standards. The core components of such a program include comprehensive curriculum covering energy control procedures, hazard identification, and proper lockout/tagout techniques specific to hydraulic equipment. Hands-on exercises and realistic scenario simulations are essential, allowing trainees to apply theoretical knowledge in practical situations.

Moreover, training should emphasize the importance of consistent adherence to safety protocols, proper labeling and documentation practices, and regular maintenance of lockout devices. Incorporating ongoing refresher courses and fostering a culture of open communication about safety concerns further strengthens lockout/tagout compliance, minimizing risks associated with energy-related hazards in hydraulic systems.

Practical Application and Scenario-Based Learning

Practical application and scenario-based learning are integral components of effective hydraulic system lockout training. This hands-on approach allows trainees to gain real-world experience while adhering to OSHA lockout/tagout standards, a crucial aspect of ensuring safety in industrial settings. Through interactive simulations, participants learn to identify potential hazards, implement energy control procedures, and properly apply lockout devices.

Scenario-based learning provides a dynamic environment where trainees can navigate complex situations. By confronting realistic scenarios, they develop critical thinking skills and enhance their understanding of OSHA’s guidelines for lockout tagout compliance. This practical experience not only reinforces knowledge but also prepares them to handle emergency situations confidently, ultimately contributing to a safer workplace culture.

Common Mistakes and How to Avoid Them

Many workplace accidents involving machinery and equipment can be attributed to mistakes made during hydraulic system lockout procedures. A common blunder is failing to properly identify and isolate energy sources, leading to unexpected activation during testing or maintenance. This often occurs when workers rush the process, overlooking critical steps like verifying all controls are in the off position and disabling power sources such as electricity, hydraulics, and compressed air. Adhering strictly to OSHA lockout/tagout standards is essential; these guidelines provide a structured framework for ensuring energy control procedures are carried out safely.

To avoid these pitfalls, comprehensive lockout tagout compliance training is imperative. Employees should be taught to meticulously document each step of the process, from tagging out equipment to verifying the effectiveness of the lockout. Regular practice sessions and mock scenarios can help familiarize workers with the procedure, ensuring they react swiftly and accurately in real-time situations. By prioritizing safety through rigorous energy control procedures training, companies can significantly reduce risks and create a more secure work environment.

Continuous Improvement and Staying Compliant

In the ever-evolving landscape of industrial safety, continuous improvement and staying compliant with regulations like OSHA’s lockout/tagout standards are non-negotiable. Lockout tagout compliance training plays a pivotal role in this regard, equipping employees with the knowledge and skills to implement energy control procedures safely and effectively. By regularly conducting such training, organizations not only ensure adherence to legal mandates but also foster a culture of proactive safety measures.

This ongoing education empowers workers to identify potential hazards, understand the importance of proper locking out equipment, and adhere to standardized protocols. It encourages a mindset shift from reactive safety practices to proactive risk management, where every employee takes ownership of their role in preventing accidents. As industrial processes become more complex, staying updated with energy control procedures training is essential to maintain a safe working environment and avoid costly compliance issues.