Regular Kitchen Suppression Inspection Spring Lake services are crucial for maintaining fire safety standards in commercial kitchens. These inspections ensure the effectiveness of kitchen suppression systems by verifying nozzle alignment, checking agent distribution, and identifying potential issues. Compliance with fire suppression regulations is vital to avoid fines, disruptions, and most importantly, to protect lives. Misaligned nozzles and non-compliance with local codes are common issues addressed through routine inspections, ensuring a secure cooking environment for all.

In the heart of every commercial kitchen lies a vital life safety system: the kitchen suppression system. Ensuring optimal performance requires regular inspections and maintenance, especially in areas like Spring Lake where fire hazards are prevalent. This comprehensive guide delves into the intricacies of kitchen suppression systems, offering a detailed look at essential components, alignment checks, common issues, and best practices to maintain fire suppression compliance. By understanding these aspects, you’ll be equipped with the knowledge to conduct thorough Kitchen Suppression Inspection in Spring Lake.

- Understanding Kitchen Suppression Systems: A Basic Overview

- The Importance of Regular Inspection and Maintenance

- Identifying Components Critical for Nozzle Alignment

- Step-by-Step Guide to Performing a Nozzle Alignment Check

- Common Issues Found During Suppression System Inspections

- Ensuring Fire Suppression Compliance in Spring Lake Kitchens

- Best Practices for Maintaining Kitchen Suppression Systems

Understanding Kitchen Suppression Systems: A Basic Overview

Suppression systems are critical safety features in commercial kitchens and food preparation areas, designed to combat fires swiftly and effectively. These systems typically consist of a network of pipes, nozzles, and fire suppression agents, strategically placed throughout the kitchen. The primary goal is to suppress or extinguish fires at their inception, minimizing damage and ensuring the safety of occupants.

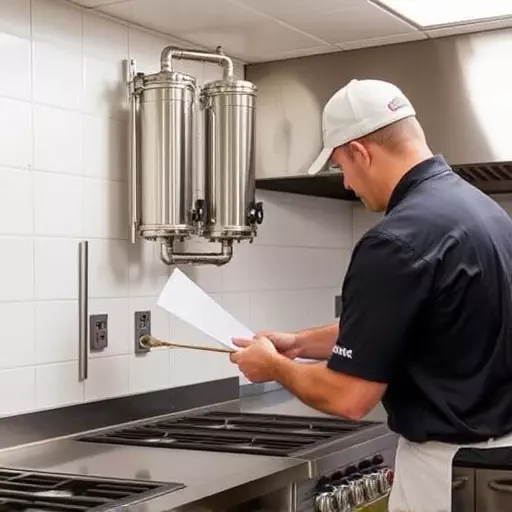

A Kitchen Suppression Inspection Spring Lake professional should have a thorough understanding of these systems to conduct efficient Fire Suppression Compliance Checks. Regular inspections are essential to verify the operational readiness of nozzles, ensure proper agent distribution, and identify any potential issues or blockages. By maintaining these systems, you adhere to local fire safety regulations and protect your establishment from devastating kitchen fires.

The Importance of Regular Inspection and Maintenance

Regular inspections and maintenance are paramount for any kitchen suppression system in Spring Lake. Fire suppression systems, like any other mechanism, require routine care to ensure optimal performance during an emergency. A kitchen suppression inspection involves a thorough check of each nozzle, ensuring they are aligned correctly and free from any blockages. This simple yet critical task can prevent costly repairs and even save lives by guaranteeing the system’s reliability when needed most.

Non-compliance with fire suppression regulations can lead to severe consequences, including fines and potential business disruptions. Property owners and managers must stay up-to-date with regular kitchen suppression system inspections to maintain compliance. By doing so, they contribute to a safer environment for staff and customers alike, ensuring that the suppression system functions as intended in case of a fire outbreak.

Identifying Components Critical for Nozzle Alignment

In the context of fire safety in commercial kitchens, especially in areas like Spring Lake, thorough kitchen suppression inspection is paramount. The process involves meticulous identification and evaluation of several critical components to ensure optimal nozzle alignment for a functional fire suppression system. Among these, the most crucial elements include the sprinkler heads (nozzles), control valves, and piping networks.

Sprinkler heads, strategically placed throughout the kitchen, are the visible indicators of the suppression system’s presence. Their proper alignment ensures that in the event of a fire, water can be directed precisely onto the flames. Control valves regulate the flow of water to these nozzles, while piping networks distribute water supply to each sprinkler head. Maintaining and aligning these components is key to ensuring fire suppression compliance checks are passed, thereby safeguarding commercial kitchens against potential hazards.

Step-by-Step Guide to Performing a Nozzle Alignment Check

Performing a nozzle alignment check is a crucial step in ensuring your kitchen suppression system’s effectiveness and Fire suppression compliance in Spring Lake. Here’s a step-by-step guide to help you through the process:

1. Safety First: Begin by shutting off the gas supply at the main valve to ensure no fuel reaches the system during inspection. Put on personal protective equipment (PPE), including safety glasses and gloves, as a precautionary measure.

2. Inspect Visual Cues: Visually examine each nozzle for any signs of damage, corrosion, or obstruction. Ensure they are free from dust, grease, or other debris that might block their openings. Look for proper alignment with the cooking surface to guarantee optimal spray distribution during an emergency.

Common Issues Found During Suppression System Inspections

During kitchen suppression inspections in Spring Lake, several common issues are frequently encountered. One of the primary concerns is misaligned or improperly installed nozzles, which can significantly impact the effectiveness of the fire suppression system. These nozzles are crucial for quickly distributing fire-retardant agents throughout the kitchen area, and even a slight misalignment can hinder their optimal performance during an emergency.

Another issue that arises often is non-compliance with local fire codes and regulations. Fire suppression systems require regular maintenance and inspections to ensure they meet safety standards. Property owners and managers in Spring Lake must be vigilant about conducting comprehensive kitchen suppression system inspections to address any deficiencies and stay up-to-date with fire suppression compliance checks. Regular attention to these details can prevent potential hazards and ensure the safety of occupants in commercial kitchens.

Ensuring Fire Suppression Compliance in Spring Lake Kitchens

In commercial kitchens, especially in areas like Spring Lake, maintaining robust fire suppression systems is non-negotiable. Regular Kitchen Suppression Inspection Spring Lake plays a pivotal role in ensuring Fire Suppression Compliance. These inspections are meticulously designed to verify that every component of the kitchen’s suppression system functions optimally and is aligned correctly. This includes checking nozzle alignment, testing fire suppression agent levels, inspecting equipment for any signs of damage or wear, and verifying the integrity of all connections.

By conducting thorough Kitchen suppression system inspection, professionals can identify potential issues early on, preventing catastrophic failures during a fire emergency. Staying up-to-date with these compliance checks is essential not only for the safety of patrons and staff but also for legal adherence. Local regulations mandate regular inspections to maintain Fire Suppression Compliance, ensuring that kitchens in Spring Lake are prepared to swiftly suppress fires, minimizing damage and loss of life.

Best Practices for Maintaining Kitchen Suppression Systems

Maintaining a kitchen suppression system is paramount for fire safety in any commercial cooking facility. Regular Kitchen Suppression Inspection Spring Lake should be part of your routine maintenance schedule to ensure optimal performance when it matters most. A comprehensive inspection includes visually examining all components, testing sprinkler heads for proper alignment and functionality, checking fire suppression agents’ levels, and verifying the integrity of control valves.

Best practices involve scheduling inspections at least annually or more frequently if your kitchen sees heavy use. Keep detailed records of each inspection, noting any repairs or maintenance required. Ensure staff are trained to recognize potential issues and report them promptly. Regular cleaning and testing of suppression system components not only maintains compliance with fire codes but also guarantees the system’s effectiveness in suppressing fires quickly and efficiently.